Mold and method for ring hoop tension tests of small polymer pipes

A technology of hoop stretching and testing molds, which is applied in the field of medical devices and can solve problems such as difficult to apply, few, and difficult stretching tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

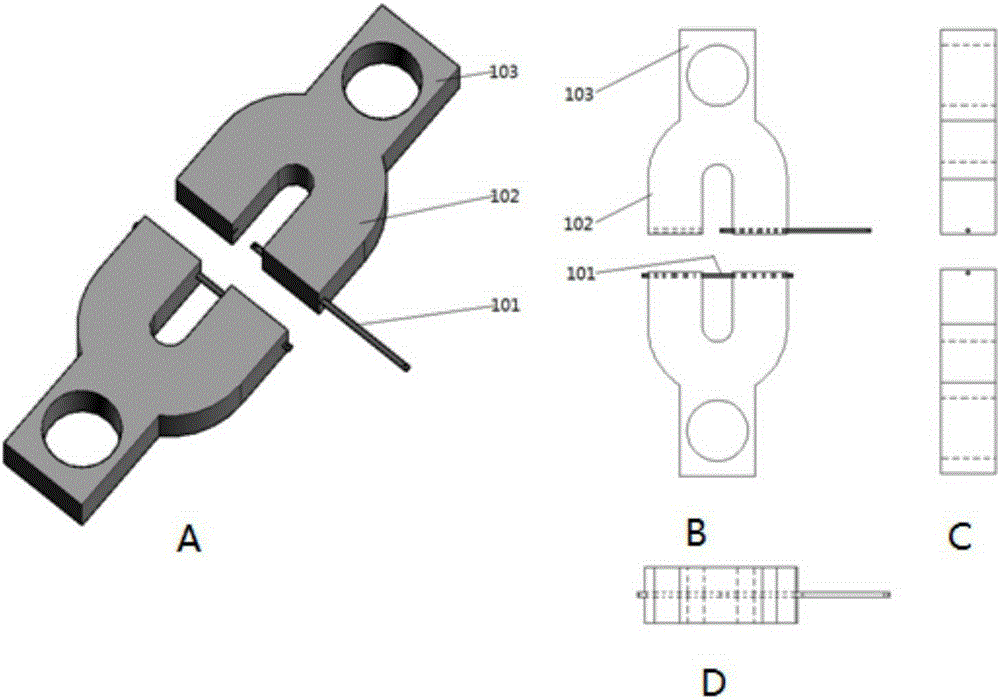

[0111] refer to figure 1 As shown, a mold for the tensile test of the hoop performance of small polymer pipes includes: a stressed bar 101, a main body device 102, and a connecting part 103; wherein the stressed bar 101 is installed on one side of the main body device 102, and can be Pass through the inside of the small polymer pipe along the axial direction of the small polymer pipe; the connecting parts 103 are arranged on the left and right sides of the main device 102 and are used to connect the mold and the stretching module. The force bar 101 is a regular hexagonal prism with a bottom side length of 0.70 mm and a length of 10 mm. It is made of high-strength steel with a roughness of 0.05 and a distance of 0.50 mm from the top of the main device 102. Among them, the force bar 101 uses two ends Both ends are detachable, and both ends are fixed on the main device 102 with sheaths; the left and right sides of the main device 102 are cubes, with a length of 18.00 mm, a width ...

Embodiment 2

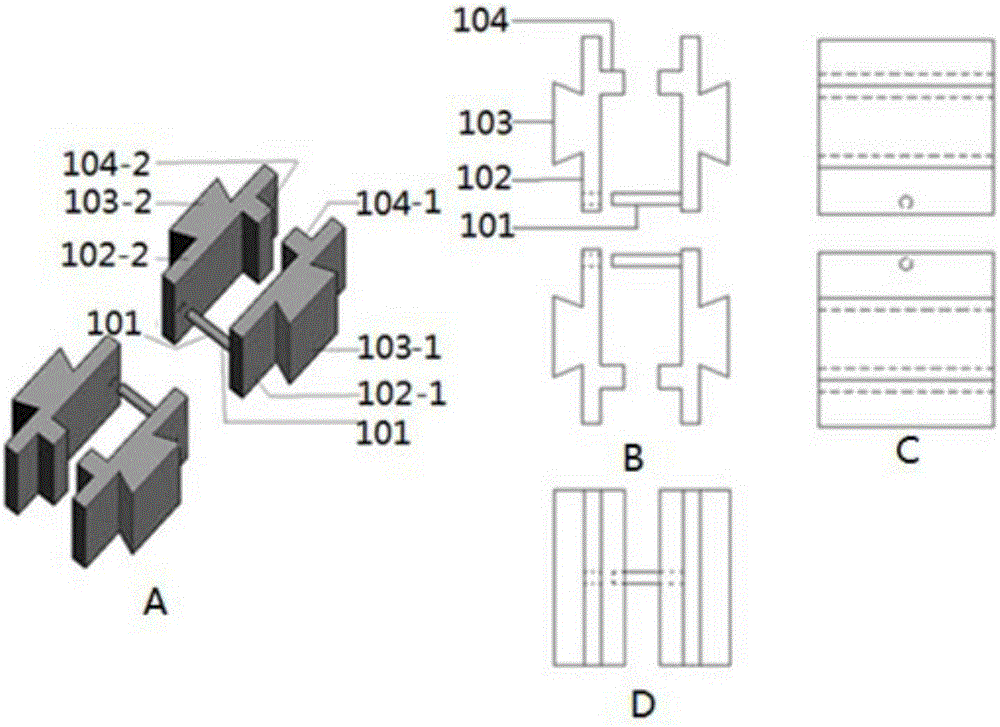

[0114] refer to figure 2 As shown, a mold for the tensile test of the hoop performance of small polymer pipes includes: a stressed bar 101, a main body device 102, and a connecting part 103; wherein the stressed bar 101 is installed on one side of the main body device 102, and can be The small polymer tube passes through the lumen of the small polymer tube along the axial direction; the connecting parts 103 are arranged on the left and right sides of the main device 102 and are used to connect the mold and the stretching module. The main device 102 is further subdivided into a distal fixing part 104 and a proximal top, and the distance between the force bar 101 and the proximal top of the main device 102 is 0.50 mm. The force bar 101 is a cylinder with a diameter of 1.00mm and a length of 10mm, made of No. 45 steel with a roughness of 0.008; the main device 102 (102-1 and 102-2), the connecting parts 103 (103-1 and 103- 2), the fixing parts 104 (104-1 and 104-2) are composed...

Embodiment 3

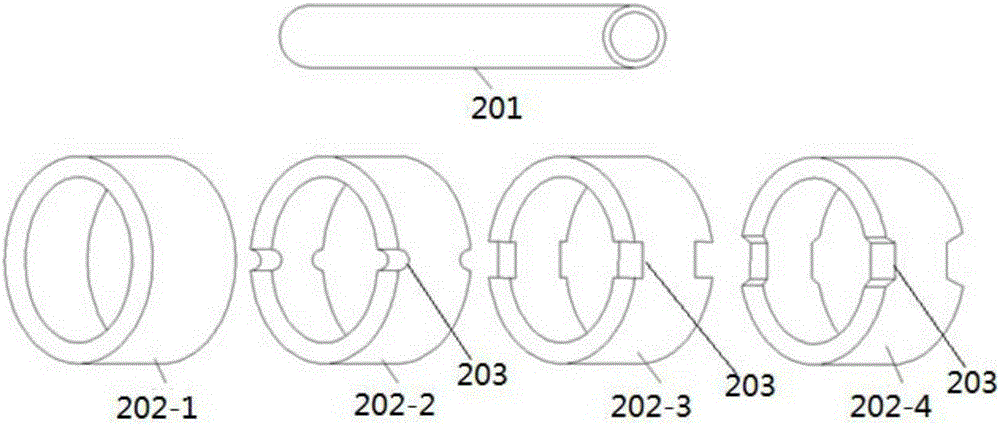

[0117] refer to Figure 6 As shown, a mold for the tensile test of the hoop performance of small polymer pipes includes: a stressed bar 101, a main body device 102, and a connecting part 103; wherein the stressed bar 101 is installed on one side of the main body device 102, and can be The small polymer tube passes through the lumen of the small polymer tube along the axial direction; the connecting parts 103 are arranged on the left and right sides of the main device 102 and are used to connect the mold and the stretching module. The main device 102 is further subdivided into a distal fixing part 104 and a proximal top, and the distance between the force bar 101 and the proximal top of the main device 102 is 0.50 mm. The force bar 101 is a half cylinder with a diameter of 1.00mm and a length of 10mm, made of No. 45 steel with a roughness of 0.8; the main device 102 is composed of two symmetrical parts, wherein the main device 102 is a cuboid with a length of 50.00mm , with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com