Centrally-installed switchgear intelligent maintenance dolly

A technology of central cabinets and trolleys, applied to switchgear, electrical components, etc., to achieve the effects of shortening power outage time, preventing circuit breakers from falling, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

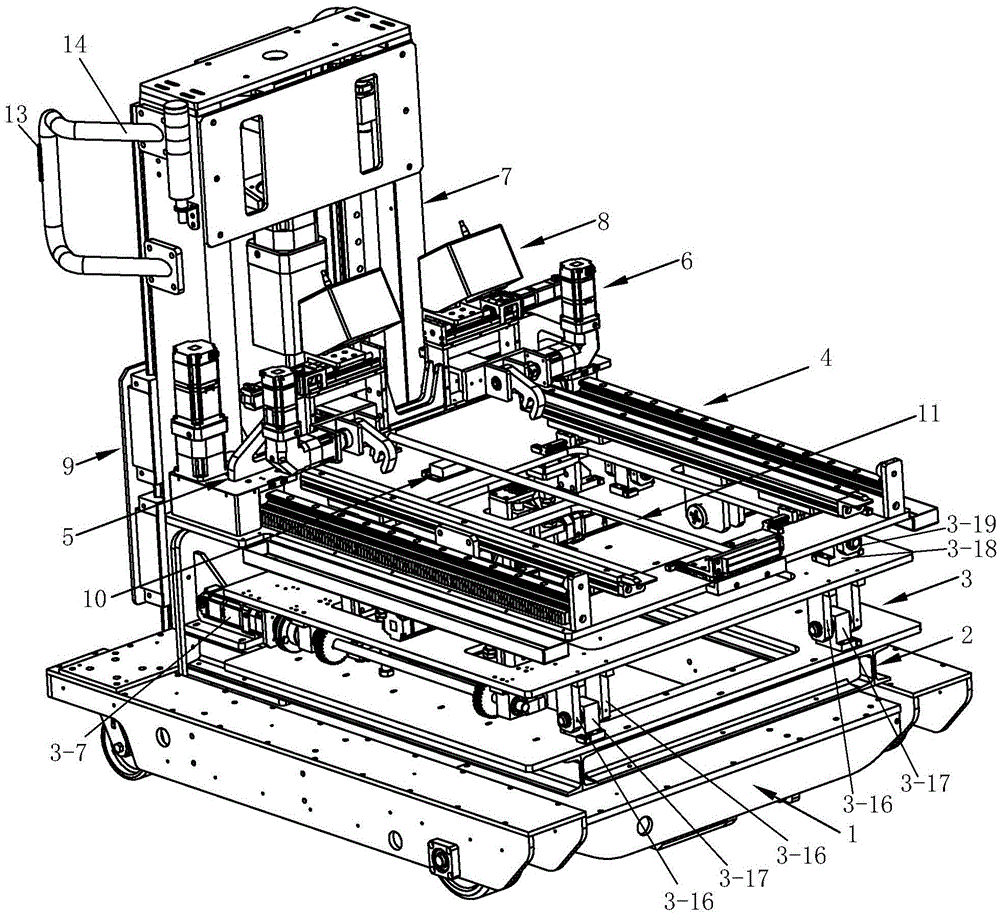

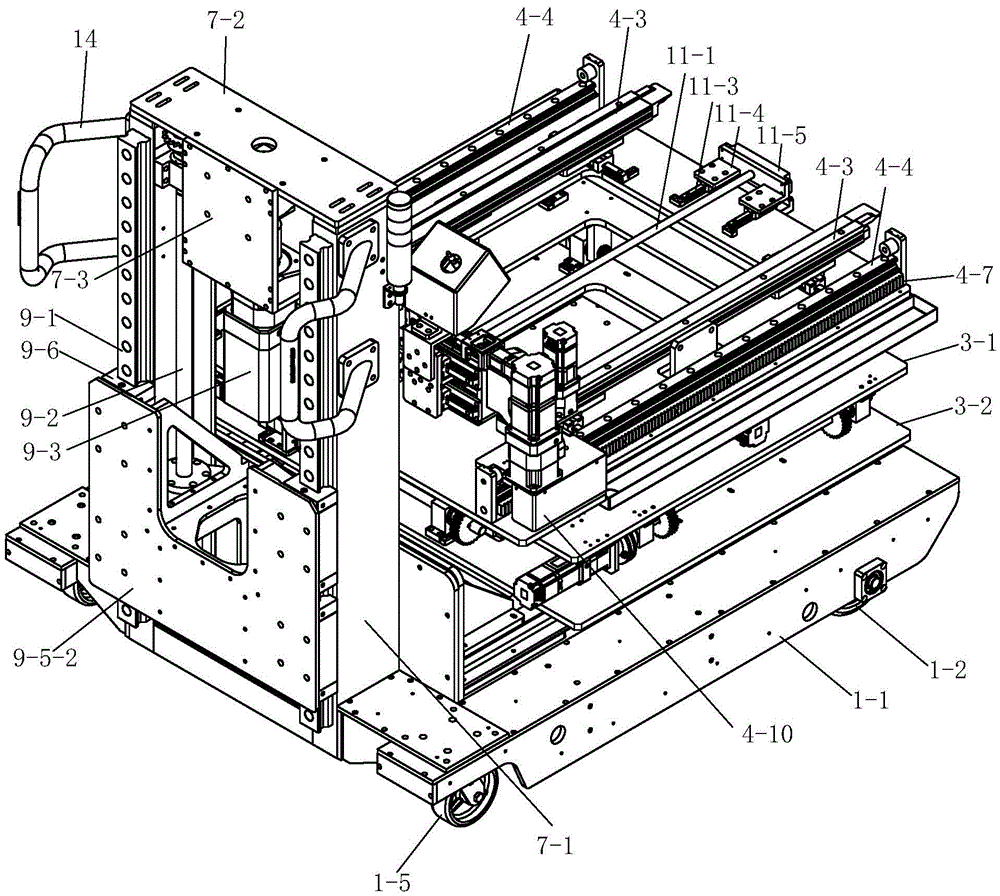

[0039] See figure 1 and figure 2 , this embodiment includes a chassis 1 , a load-bearing tray 2 , a horizontal adjustment platform 3 , a carrying platform 4 , a top frame 5 and two grabbing devices 6 .

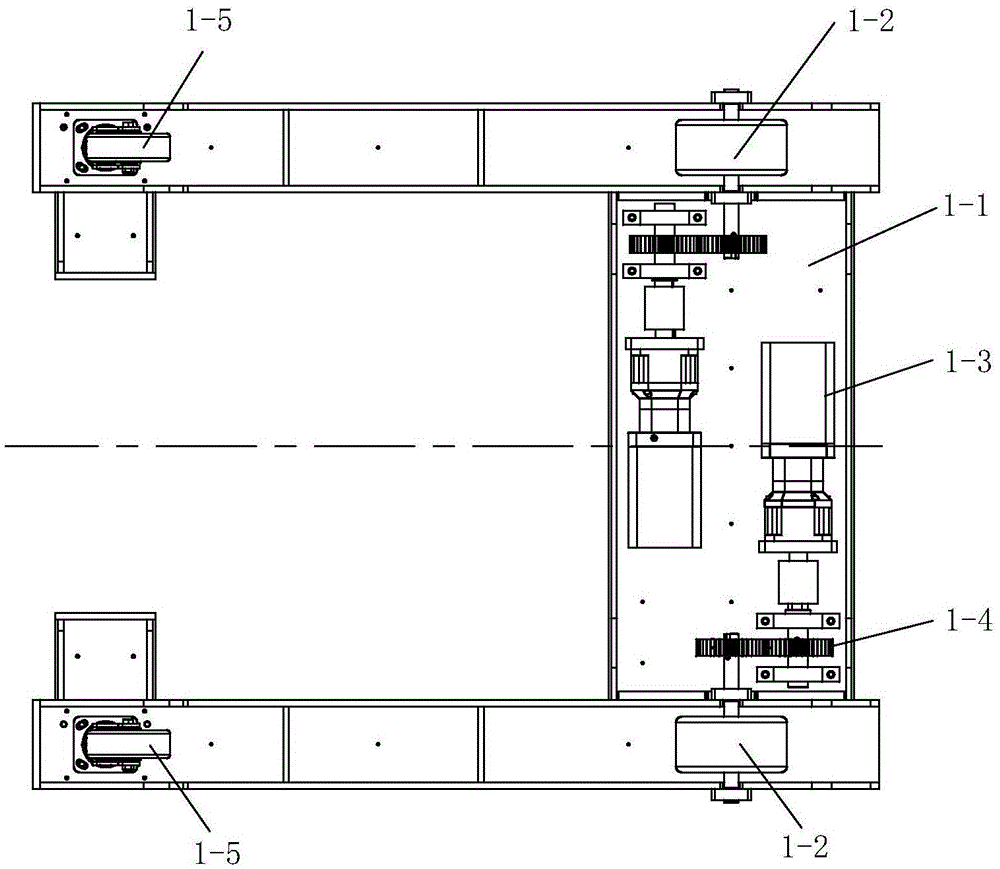

[0040] See image 3 and Figure 5, the chassis 1 has a chassis 1-1, a pair of driving wheels 1-2 and a pair of universal wheels 1-5 respectively connected to the front and rear sides of the chassis 1-1, and the driving wheels 1-2 are respectively composed of The driving servo motor 1-3 is driven by a gear transmission pair 1-4.

[0041] See figure 1 , figure 2 , Figure 4 to Figure 6 , the rear side of the chassis 1 is fixed with a support frame 7, and the support frame 7 includes a pillar 7-1 arranged on the left and right sides and a top plate 7-2 fixed on the two pillars 7-1, and the top plate 7 with the top plate 7. -2 phase fixed motor brackets 7-3. The support frame 7 is provided with a lifting mechanism 9, and the lifting mechanism 9 includes two lifting guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com