Centrifugal force pendulum having an impact damper

A centrifugal force pendulum and shock absorber technology, applied in the field of centrifugal force pendulum, can solve the problems of wear, damage and unpleasantness of the pendulum mass, and achieve the effect of prolonging the service life and uniform wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

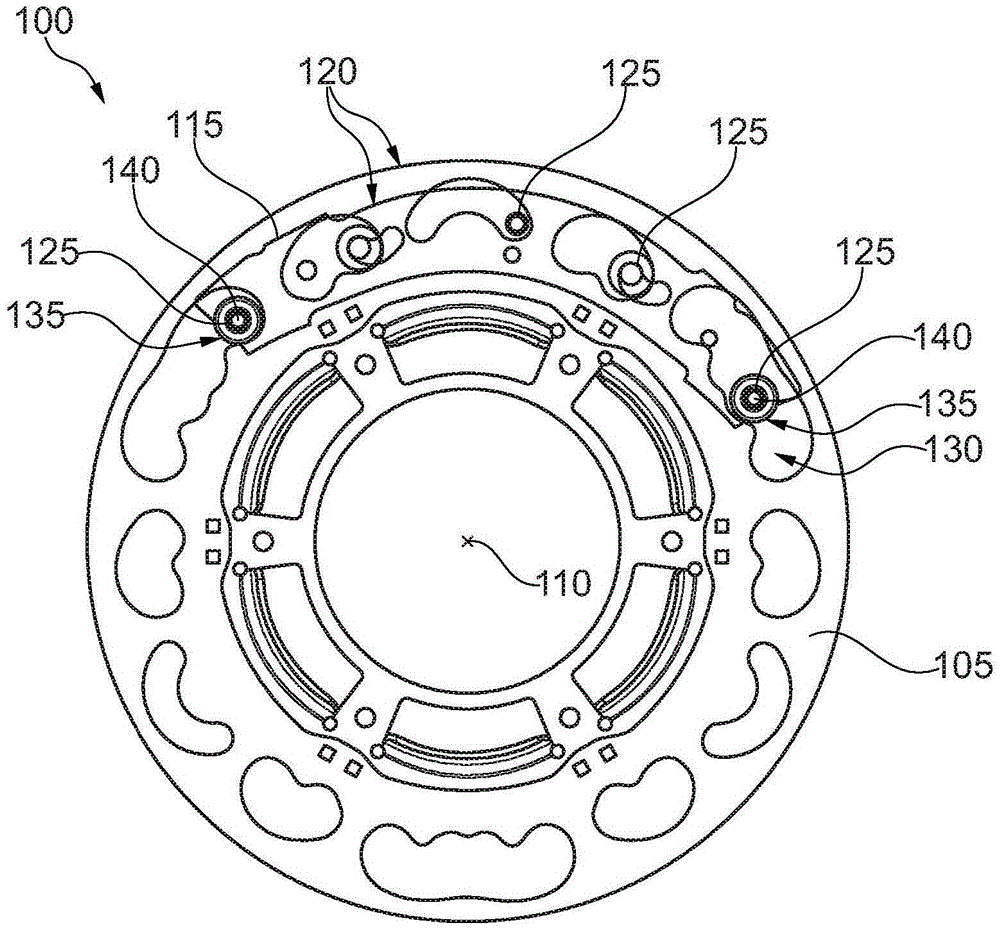

[0020] figure 1 Shown is a centrifugal pendulum 100 which is provided in particular for use in a drive train of a motor vehicle. Centrifugal pendulum 100 comprises a pendulum flange 105 , which is mounted rotatably about an axis of rotation 110 , and a pendulum mass 115 mounted on the pendulum so that it can move in a plane of rotation about the axis of rotation 110 . on flange 105. Pendulum mass 115 is shown transparently to better illustrate its support on pendulum flange 105 . In the illustrated embodiment, the pendulum mass 115 comprises two pendulum elements 120 which are mounted on different axial sides of the pendulum flange 105, but other embodiments are also possible, for example with respect to the pendulum method Lan 105 is an asymmetrical embodiment.

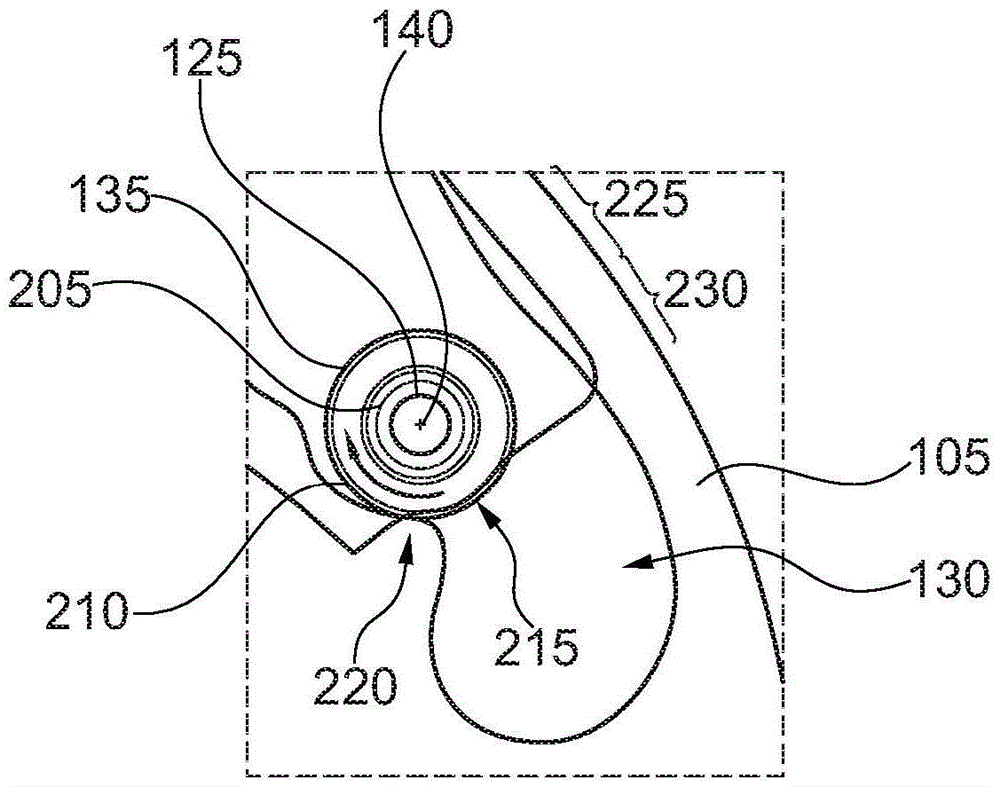

[0021] The pendulum elements 120 are connected to one another by means of one or more pins 125 . Each pin 125 extends axially through a corresponding recess 130 of the pendulum flange 105 . In this case, the del...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com