Shoe with shoe lace tightness capable of being automatically adjusted

An automatic adjustment and shoelace technology, applied in footwear, fasteners, clothing, etc., can solve the problems of cumbersome time-consuming, troublesome, pain, etc., and achieve the effect of reasonable design, convenient wearing and taking off, and improved comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

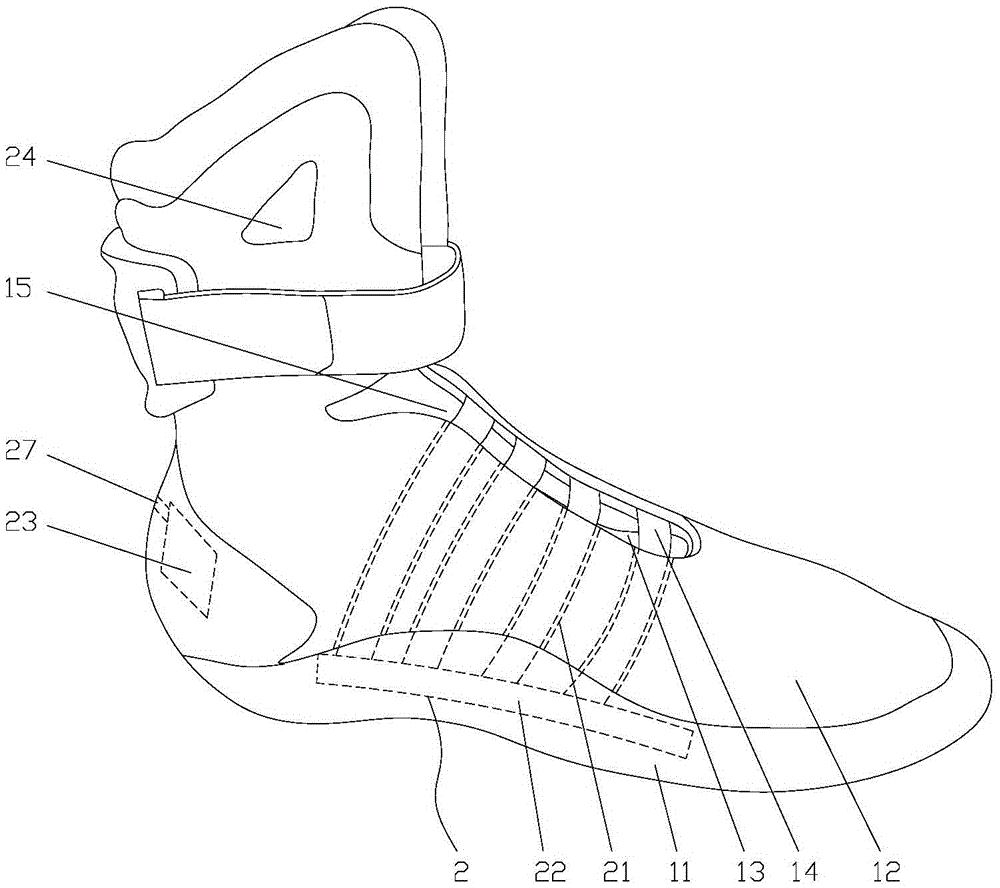

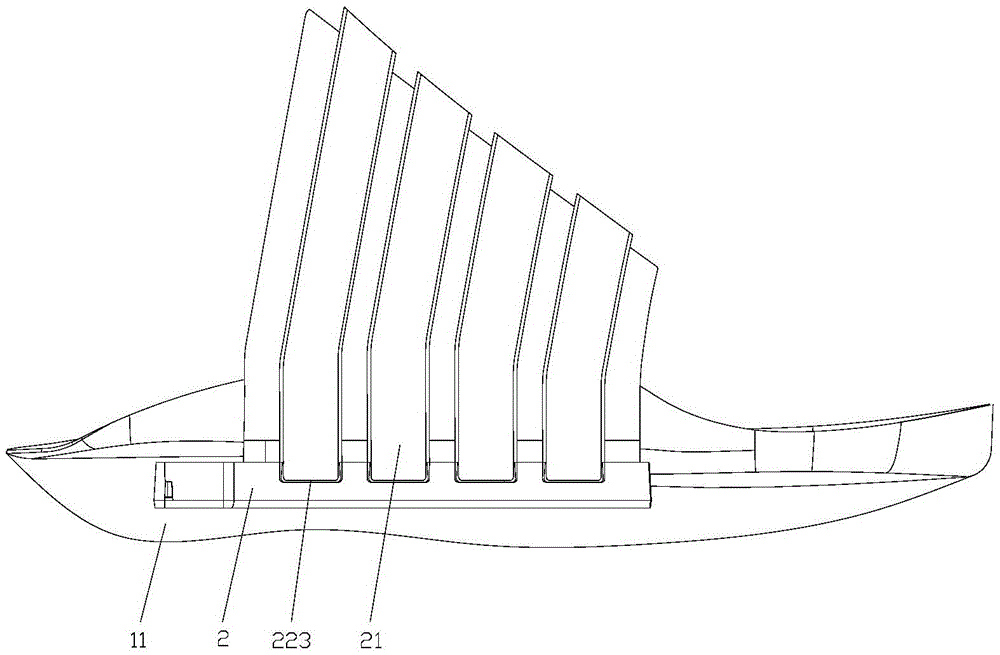

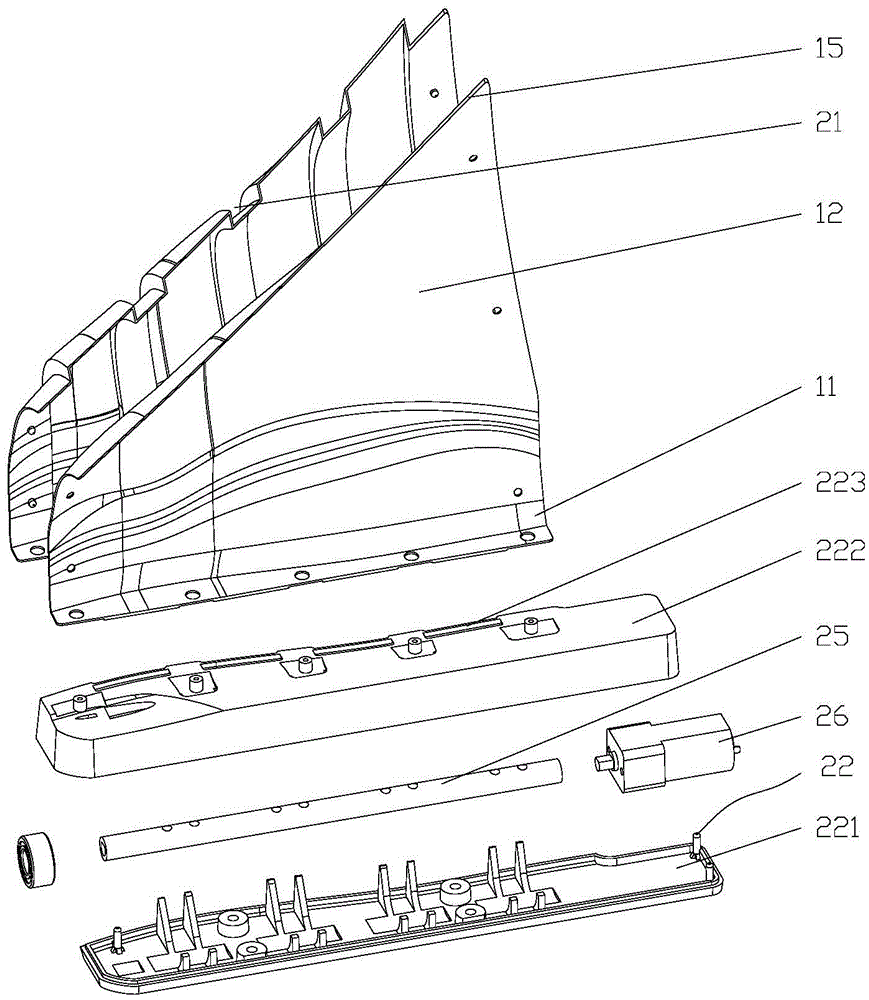

[0026] Such as Figure 1-3 As shown in one of them, the present invention comprises sole 11, vamp 12, shoe tongue 13 and several shoelaces 14, and vamp 12 is fixedly connected on the upper surface of sole 11, and the middle part of vamp 12 is provided with U-shaped opening 15, and shoe tongue 13 It is fixedly connected to the front end of the opening 15, and it also includes a hidden electric shoelace tying device 2. The hidden electric shoelace tying device 2 includes several guide rails 21, a protective case 22, a power supply 23 and a controller 24. The guide rails 21 are all arranged in the shoe upper 13 on one side of the opening 15, and extend from the side edge of the opening 15 to the direction of the sole 11. The protective shell 22 is arranged in the sole 11 on the same side as the guide rail 21. There is a shaft 25 and a motor 26 for driving the shaft 25 to rotate, the motor 26 is electrically connected to the power supply 23 arranged in the sole 11, and the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com