Rubber-coated structure of high-speed food processor drive gear

A technology of driving gear and rubber-encapsulated structure, applied in the field of cooking machines, can solve the problems of large vibration and noise in the connection structure between the cup body and the base, and achieve the effects of improving the crushing effect, improving the fit, and reducing the transmission vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0026] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

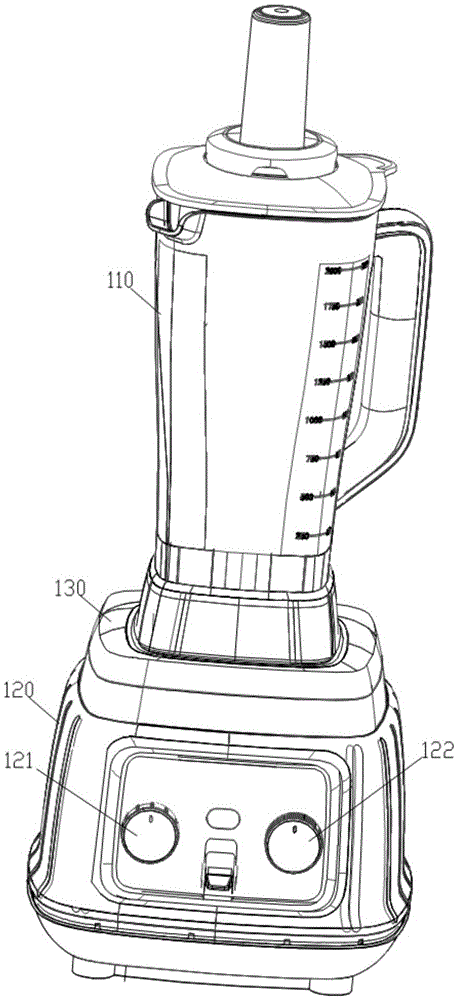

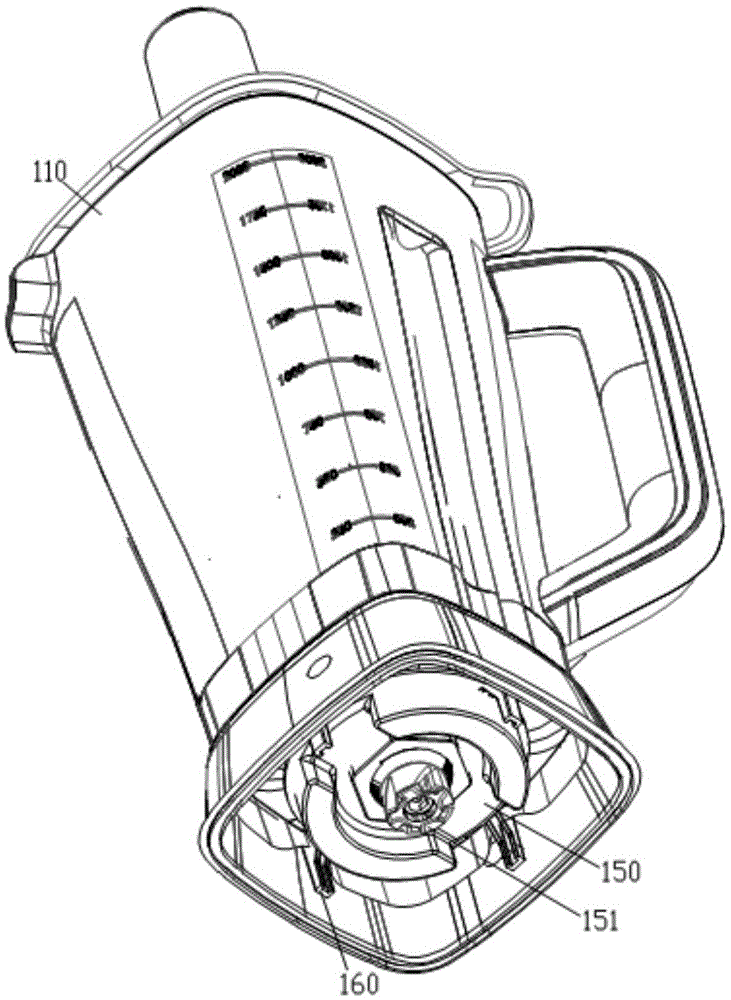

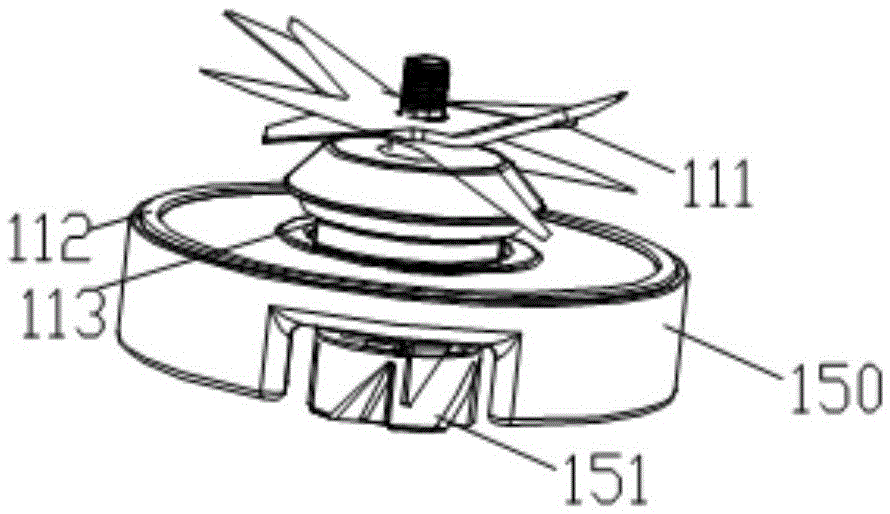

[0027] Such as Figure 1-6 As shown, the present invention provides a rubber-encapsulated structure for the driving gear of a high-speed cooking machine, including: a base 120, a cup body 110, a blade 111 and a motor installed in the base, and the blade 111 is driven by a soft rubber sleeve 172 The seat 170 is drivingly connected with the motor, so as to realize the driving connection between the blade and the motor, and the motor drives the blade to rotate at a high speed in the cup body to crush the food in the cup body.

[0028] The rubber-encapsulated structure of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com