Aluminum profile frame corner code pressure angle mechanism

An aluminum profile and frame technology, which is applied in the field of angle pressing mechanism, can solve the problems of high labor intensity of manual work, change of frame seam gap, and high product production cost, so as to save manpower, ensure consistency, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

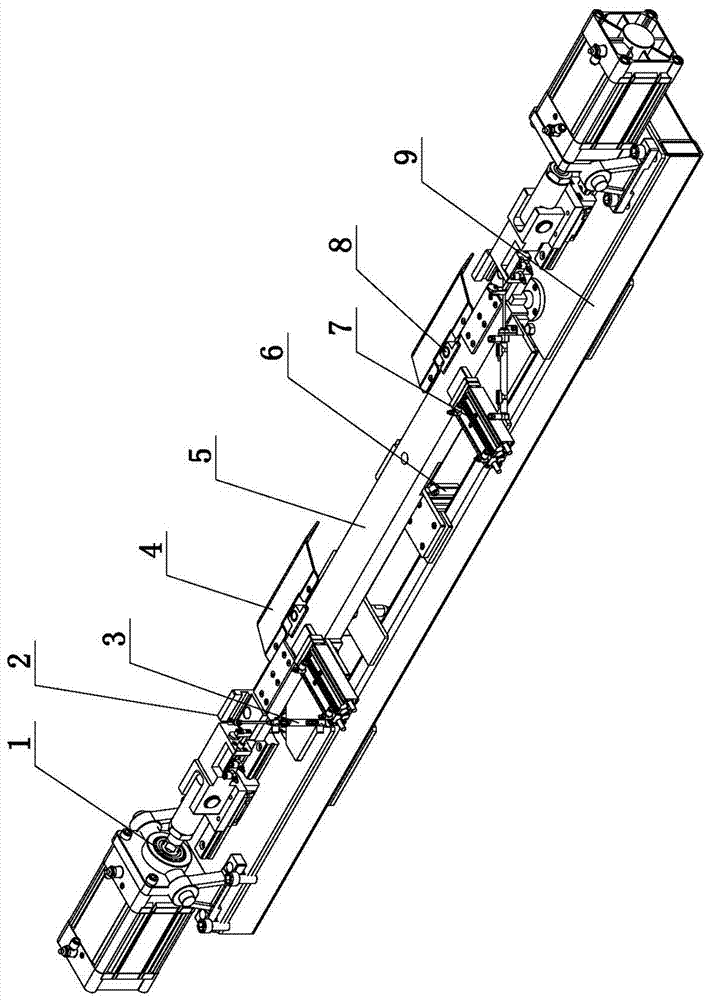

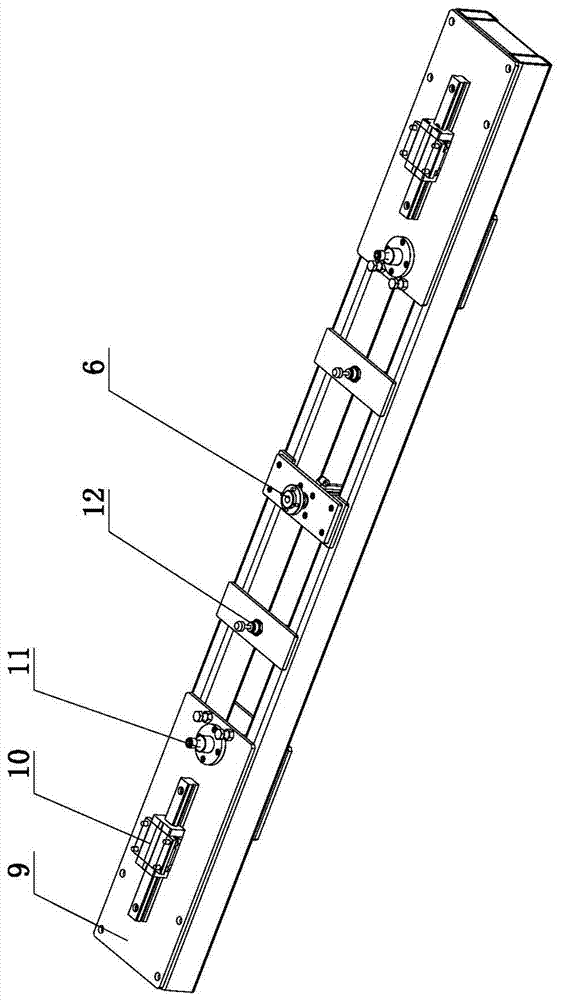

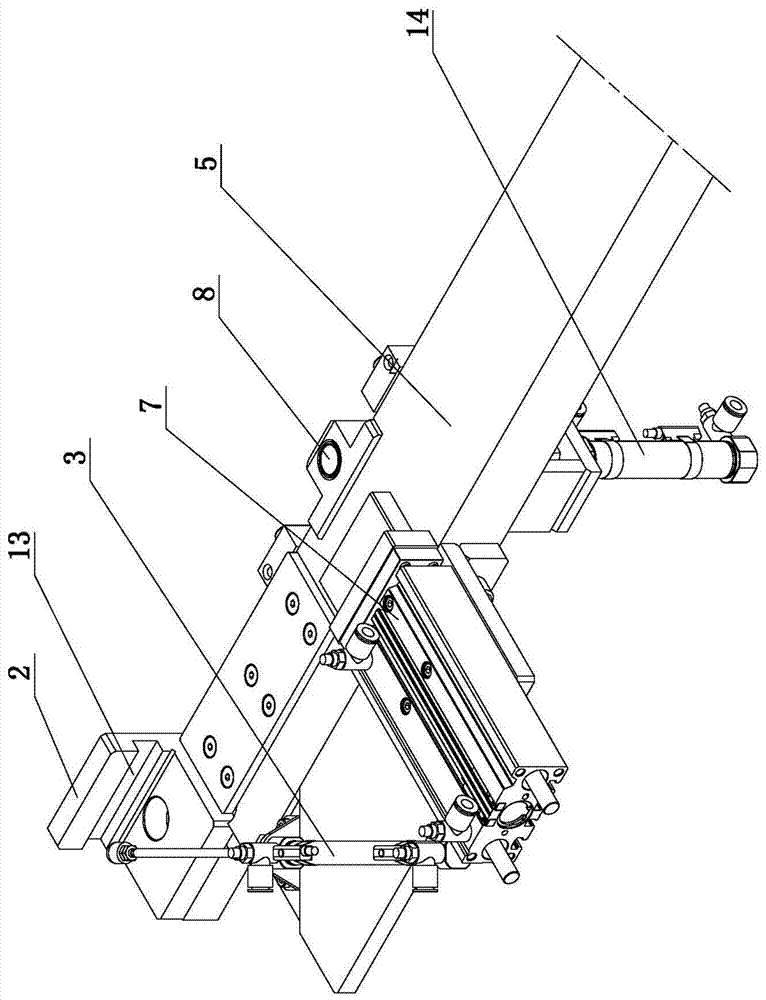

[0024] The present invention includes a frame body 9, on which a frame support 5 is arranged, and is characterized in that: one side of the frame support 5 is provided with a frame side clamping cylinder 7, and the other side of the frame support 5 positions the cylinder through the frame 14 is provided with the front positioning shaft 8 of the frame; the two ends of the frame body 9 located at the frame support 5 are respectively provided with crimping angle devices 1 .

[0025] As a preferred solution of the present invention, the crimping device 1 includes a crimping cylinder 18 arranged at both ends of the frame body 9, a crimping block 17 is arranged on the piston rod of the crimping cylinder 18, and the side of the frame support 5 Angle code positioning baffle plate 2 is provided on the side corresponding to angle code block 17; Angle code oblique push positioning cylinder 3 is provided on the frame support 5 corresponding to angle code positioning baffle plate 2 and angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com