Method for mounting larger injection mold on smaller injection molding machine

An injection mold and injection molding machine technology, which is applied in the field of injection molds, can solve the problems of high operating costs, large supporting molds, and large energy consumption, and achieve the effect of reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

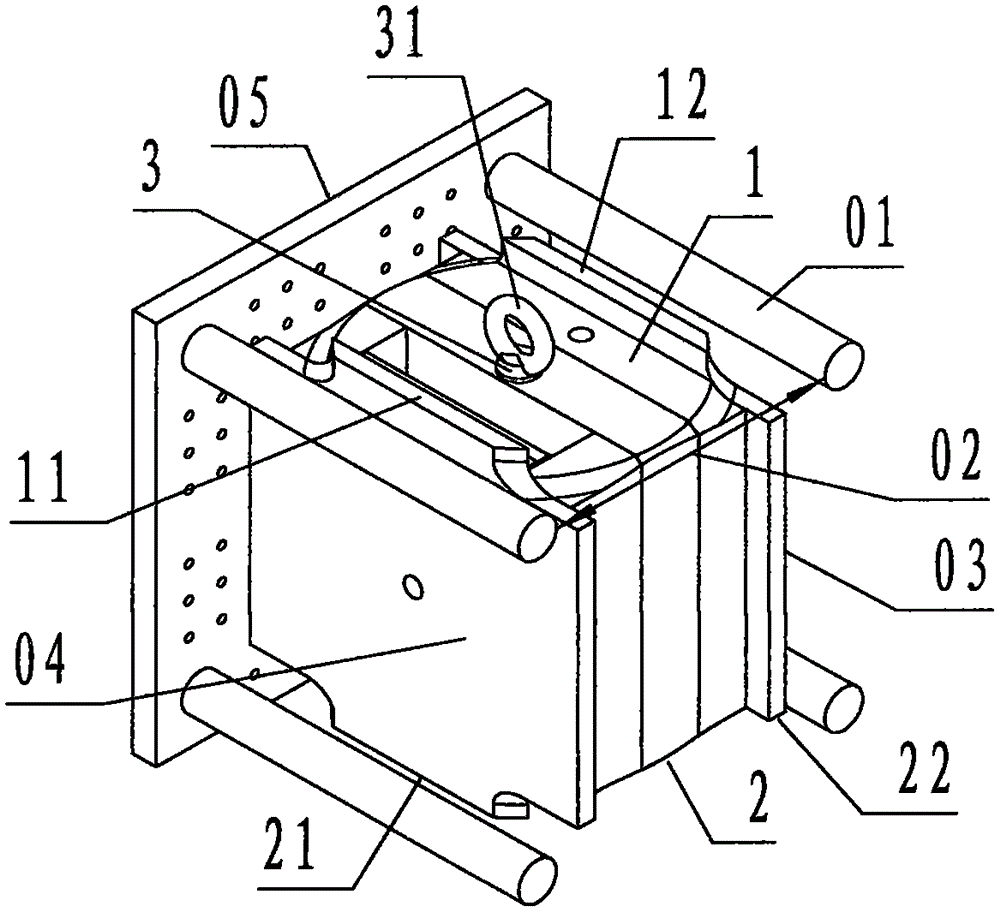

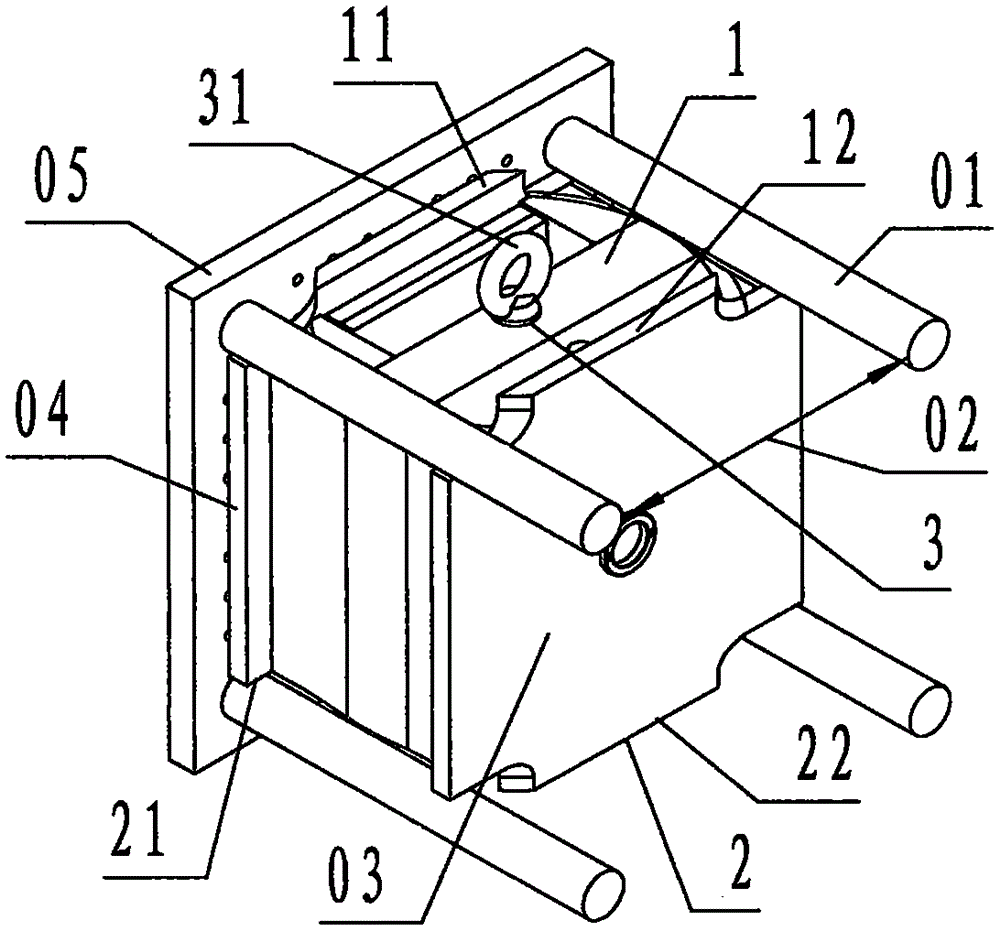

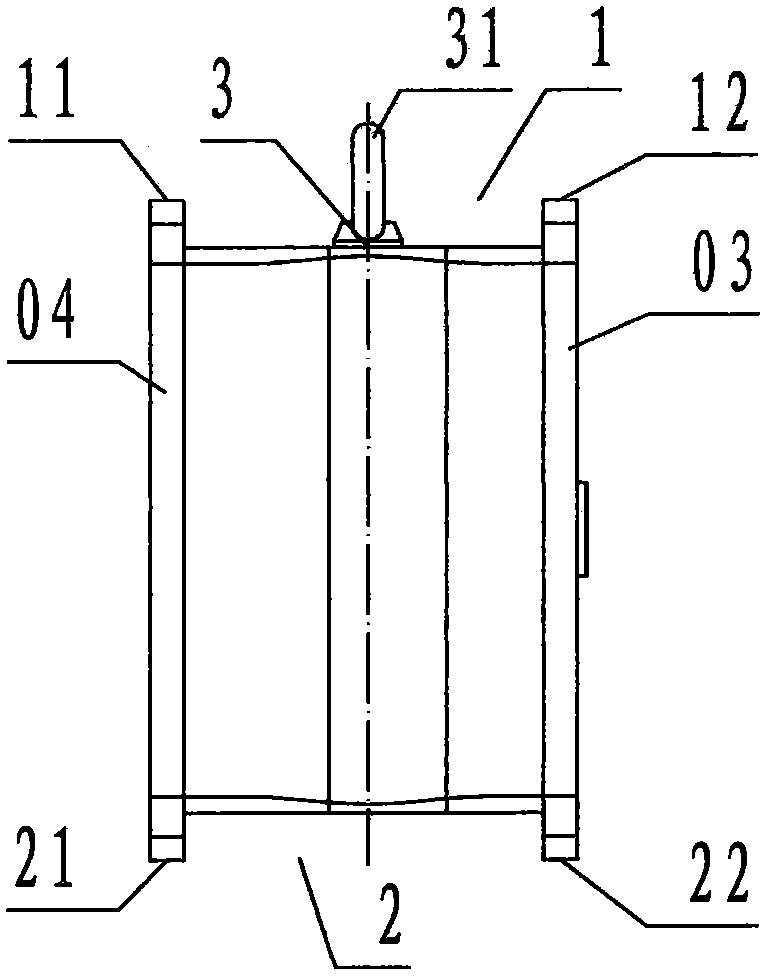

[0028] refer to Figure 1 ~ Figure 2 , a method of installing a larger injection mold on a smaller injection molding machine of the present invention, the method is as follows:

[0029] Step 1. Milling corners

[0030] Take the lifting center 3 of the mold as the center of the circle, and take the length several centimeters shorter than the mold spacing 02 of the injection molding machine as the diameter, and use a milling machine to mill the front and rear corners 06 of the bottom plate side 11 of the mold side 1 and the front and rear corners of the panel side 12 Removal, milling and removing the front and rear corners 06 of the base plate ground side 21 and the panel ground side 22 of the mold ground side 2;

[0031] Step 2. Hoisting the mold

[0032] When installing the mold, the panel 03 of the mold faces the fixed working plate of the injection molding machine, and the bottom plate 04 of the mold faces the movable working plate of the injection molding machine. When li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap