Process of producing ethylene diamine through liquid ammonia method

A technology of ethylenediamine and liquid ammonia, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of amino hydroxyl compounds, etc. It can solve the problems that it is difficult to obtain high-purity piperazine and triethylenediamine products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

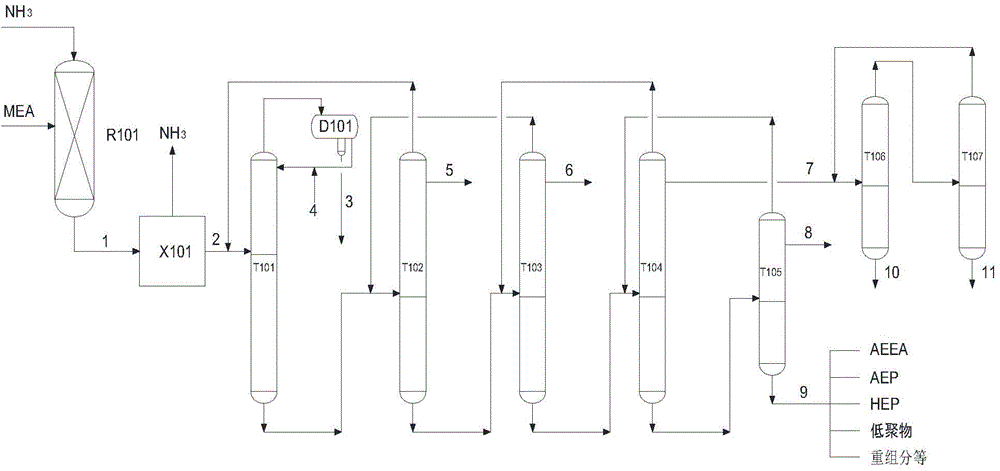

[0054] Liquid ammonia and MEA enter R101 after heating, reaction product 1 enters ammonia recovery system X101 to recover ammonia, and after ammonia is recovered, the mixture containing MEA enters dehydration tower T101 for azeotropic distillation and dehydration, waste water 3 enters post-treatment, and tower still liquid enters EDA tower T102 EDA product 5 is obtained by separation, the tower bottom liquid enters the PIP tower T103, and the PIP product is obtained by separation. Separation by pressure swing rectification in column T107, the liquid in high-pressure tower T107 is TEDA product 11, the liquid in low-pressure tower T106 is unreacted MEA10, which is recycled to reactor R101, and the liquid in heavy component separation tower T104 enters DETA tower T105 for separation to obtain DETA The product 8 and the still liquid 9, and the still liquid 9 can be further separated to obtain AEEA, AEP, HEP, oligomers, and heavy component mixed amines.

[0055] T101~T107 are all f...

Embodiment 2

[0062] Embodiment is identical with embodiment 1.

[0063] T101~T107 are all filled with 450m 2 / m 3 Metal mesh corrugated packing with specific surface area.

[0064] The operating pressure of the EDA tower T102 is 0.04MPaA, and the extraction from the top of the tower returns to the dehydration tower T101. The EDA product is extracted from the fifth theoretical plate below the top of the tower. The purity of the EDA product is ≥99.6wt%, the organic impurities are ≤0.4wt%, and the water content ≤0.4wt%, APHA≤15.

[0065] The operating pressure of the PIP tower T103 is 0.04MPaA, and the extraction from the top of the tower returns to the EDA tower T102, and the PIP product is extracted from the fourth theoretical plate below the top of the tower. The purity of the PIP product is ≥99.8wt%, the organic impurities are ≤0.2wt%, and the water content ≤0.2wt%, chroma, APHA≤30.

[0066] The operating pressure of the heavy component separation tower T104 is 20kPaA, the output from...

Embodiment 3

[0070] Embodiment is identical with embodiment 1.

[0071] T101~T107 are all filled with 550m 2 / m 3 Metal mesh corrugated packing with specific surface area.

[0072] The operating pressure of EDA tower T102 is 0.06MPaA, and the extraction from the top of the tower returns to the dehydration tower T101. The EDA product is extracted from the third theoretical plate below the top of the tower. The purity of the EDA product is ≥99.9wt%, the organic impurities are ≤0.1wt%, and the water content ≤0.1wt%, APHA≤15.

[0073] The operating pressure of the PIP tower T103 is 0.05MPaA, and the extraction from the top of the tower returns to the EDA tower T102, and the PIP product is extracted from the third theoretical plate below the top of the tower. The purity of the PIP product is ≥99.8wt%, the organic impurities are ≤0.1wt%, and the water content ≤0.1wt%, chroma, APHA≤30.

[0074] The operating pressure of the heavy component separation tower T104 is 30kPaA, the output from the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap