Clamp and anode hanger with application of clamps

A fixture and anode technology, applied in anodic oxidation, electrolytic process, electrolytic components, etc., can solve the problems of workpiece scratches and lower production yield, and achieve the effect of protecting workpiece and improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

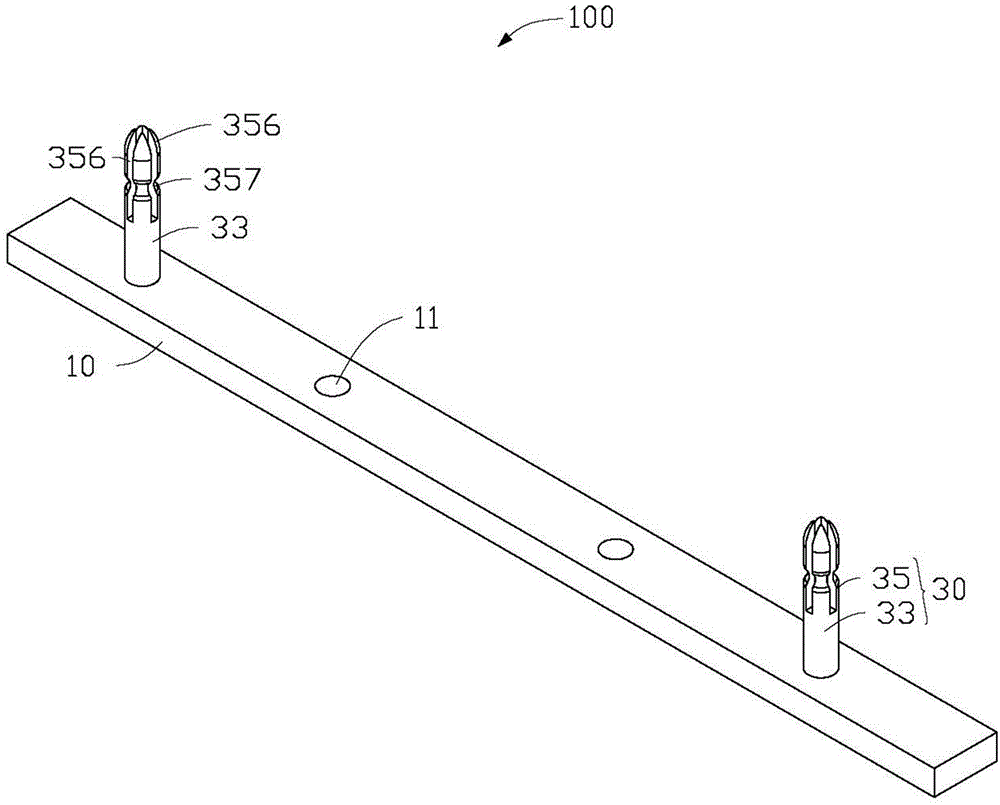

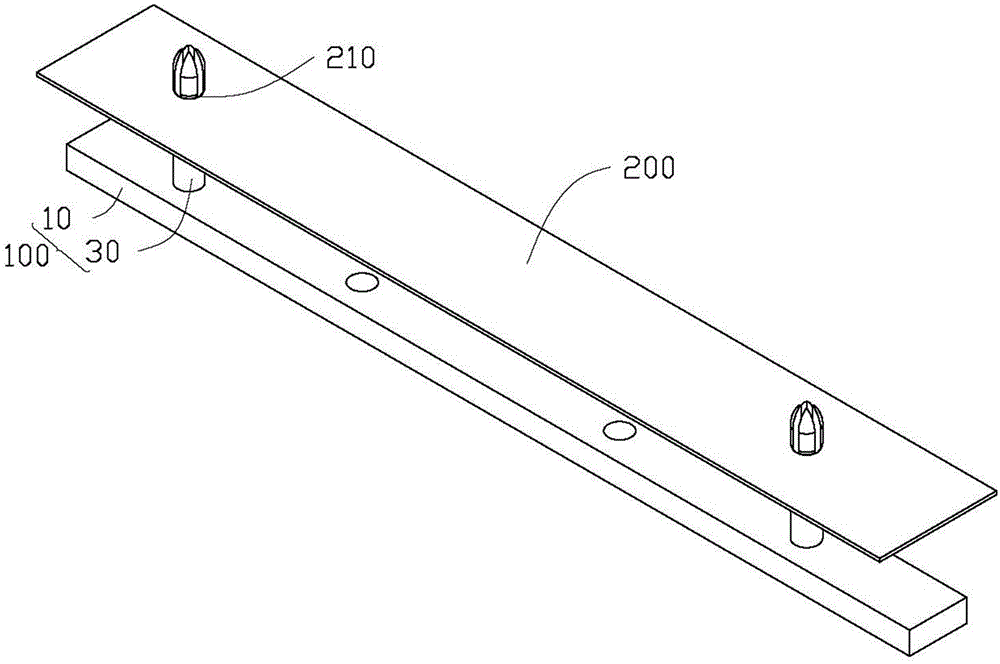

[0027] see figure 1 and figure 2 , the anode hanger 100 provided by the embodiment of the present invention is an anode anode hanger, which is used to hold the workpiece 200 (such as image 3 shown). Such as image 3 As shown, the workpiece 200 has two positioning holes 210 arranged at intervals. The positioning hole 210 is substantially a circular hole. The anode hanger 100 includes a support 10 and two clamps 30 installed on the support 10 .

[0028] see again figure 1 , the support member 10 is roughly in the shape of a bar, and a plurality of mounting holes 11 are spaced apart on it for mounting the clamp 30 . The distance between the installation holes 11 can be designed according to actual needs, so that the arrangement position of the fixture 30 can be adjusted according to the size of the workpiece 200 .

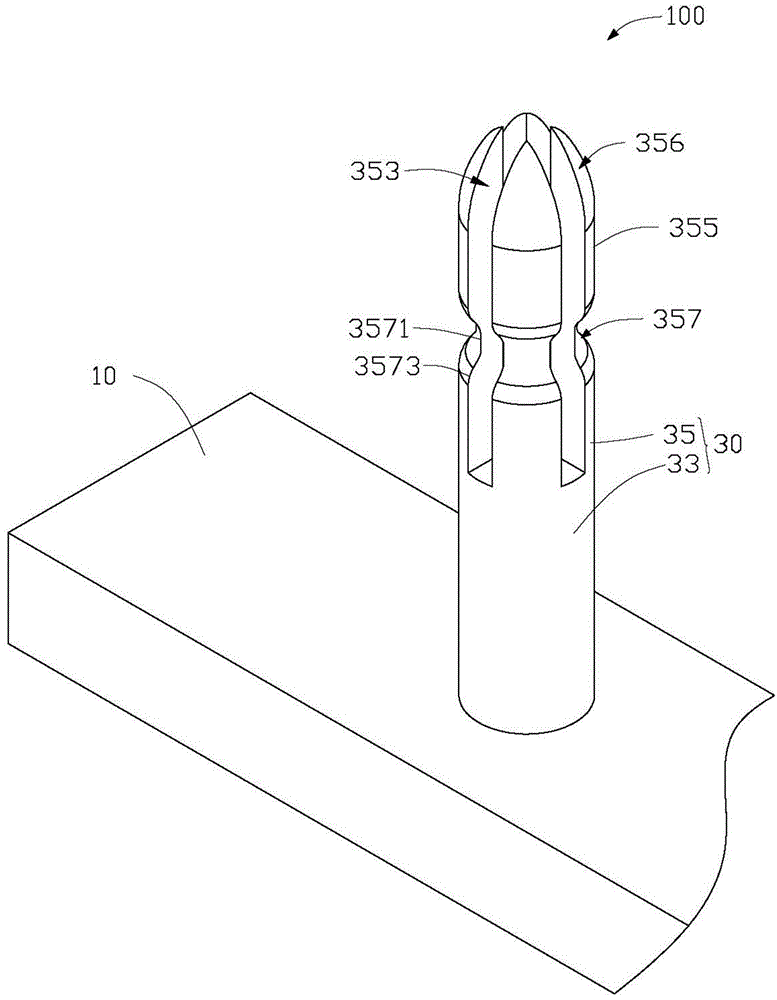

[0029] The two clamps 30 are respectively fixed on the two installation holes 11 of the support member 10 . Please also refer to figure 2 , each clamp 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com