Novel water seal adjustment valve

A technology of regulating valve and water seal, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of wasting working time, prolonging working cycle, reducing working efficiency, etc., and achieving short working cycle and high efficiency Adjustable, easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

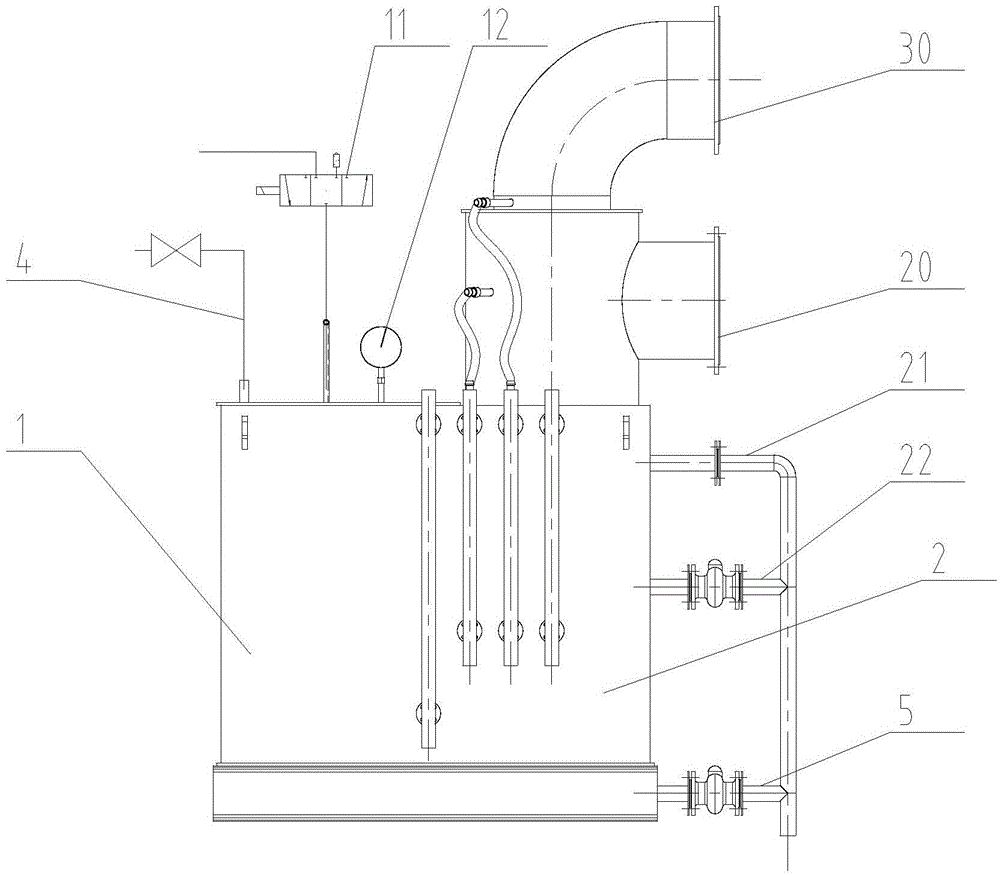

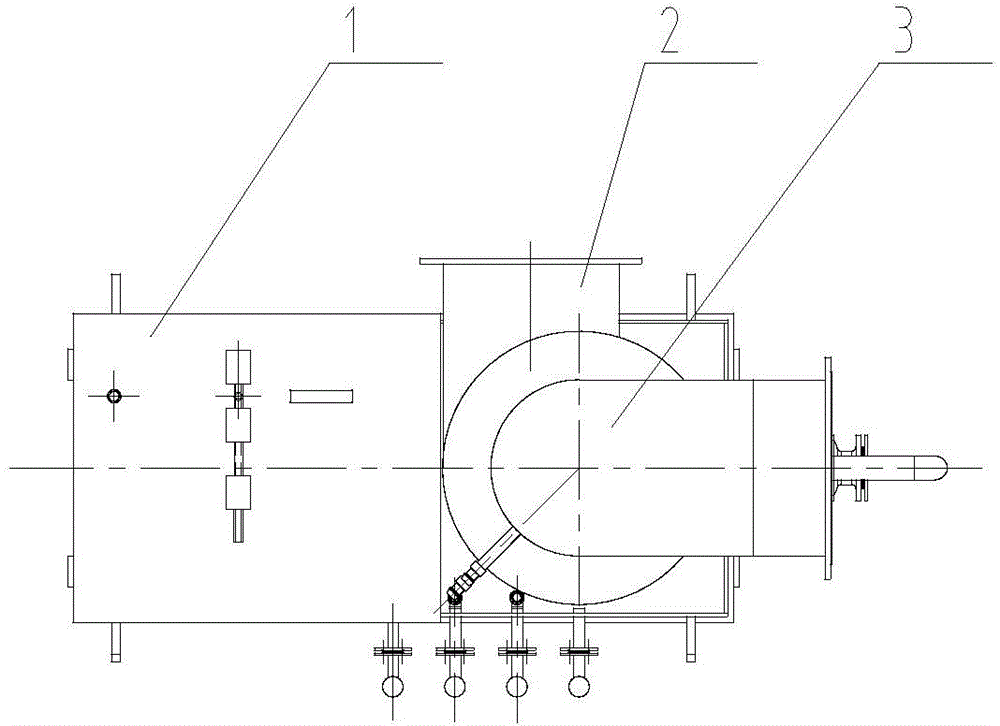

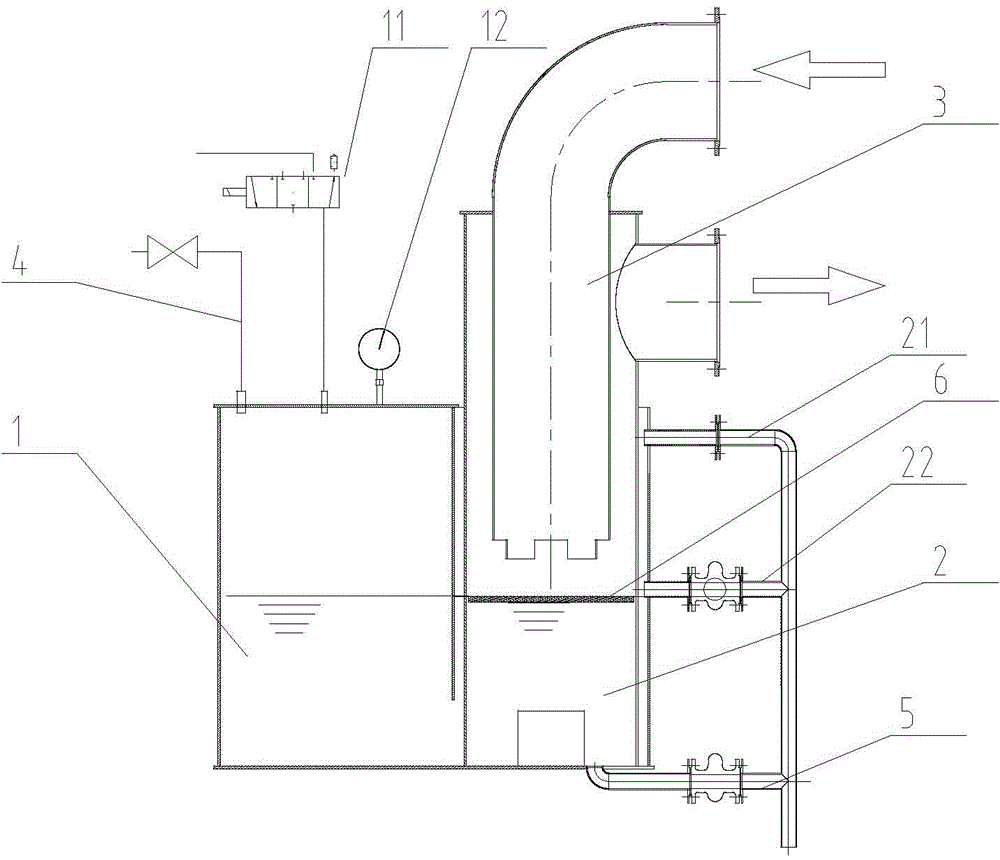

[0031] The present invention as Figure 1-5 As shown, it includes an airtight box 1, a water tank 2 and a central pipe 3, the water tank is fixed on the mounting frame, the airtight box 1 is placed on one side of the water tank 2, and the bottom of the two is connected, and the airtight The top of the tank 1 is connected to the water inlet pipe 4, and the bottom of the water tank 2 is connected to the water outlet pipe 5 (when used on a gas pipeline containing tar, waste water, solid particles, etc., the solid matter in the gas will melt into the water after passing through the water tank (commonly known in the industry as In water seal water), through regular water change and cleaning, the valve will not be unable to open and close normally, and the stability and service life of the valve will be improved. Therefore, the outlet pipe is also used for drainage, sewage, and cleaning pipes ); the center pipe 3 is vertically arranged in the water tank 2, and the top of the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com