Toilet pipe root blocking structure and construction process thereof

A construction technology, toilet technology, applied in the direction of pipes, pipes/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problem that the combination of concrete and cast-in-place slabs or floors cannot be guaranteed, water seepage or leakage at the root of the pipe, and waterproof layers are installed. Uneven sticking and other problems, to achieve the effect of ensuring the anti-leakage effect, improving the waterproof effect and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

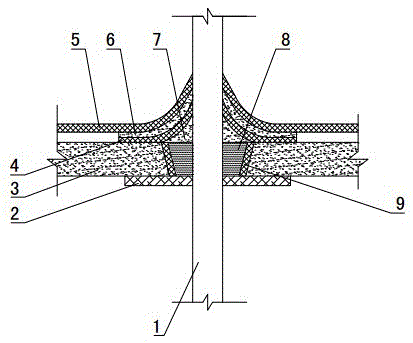

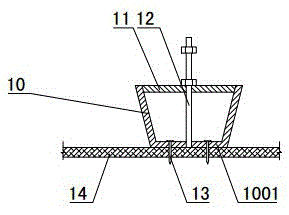

[0034] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0035] A toilet pipe root plugging structure, comprising a reserved hole arranged on the cast-in-place plate 3 of the bathroom, a pipe 1 passing through the reserved hole, and a post-casting plate 8 arranged in the reserved hole. With waterproof structure layer;

[0036] The reserved hole gradually shrinks inward from top to bottom, and the outer surface of the rear pouring plate 8 presses the inner wall of the reserved hole under the action of gravity.

[0037] The reserved holes of the pipe root plugging structure of this toilet gradually shrink inward from top to bottom, which increases the combined area of the post-casting plate 8 and the reserved holes, and the outer surface of the post-casting plate 8 is compressed under the action of gravity. The inner wall of the hole is reserved, so that the combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com