Light-sensitive SMT detecting assembly

A technology for detecting components and patches, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low detection efficiency of stencil templates, etc., and achieve the effect of reducing the workload of workers and reducing the error rate of inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

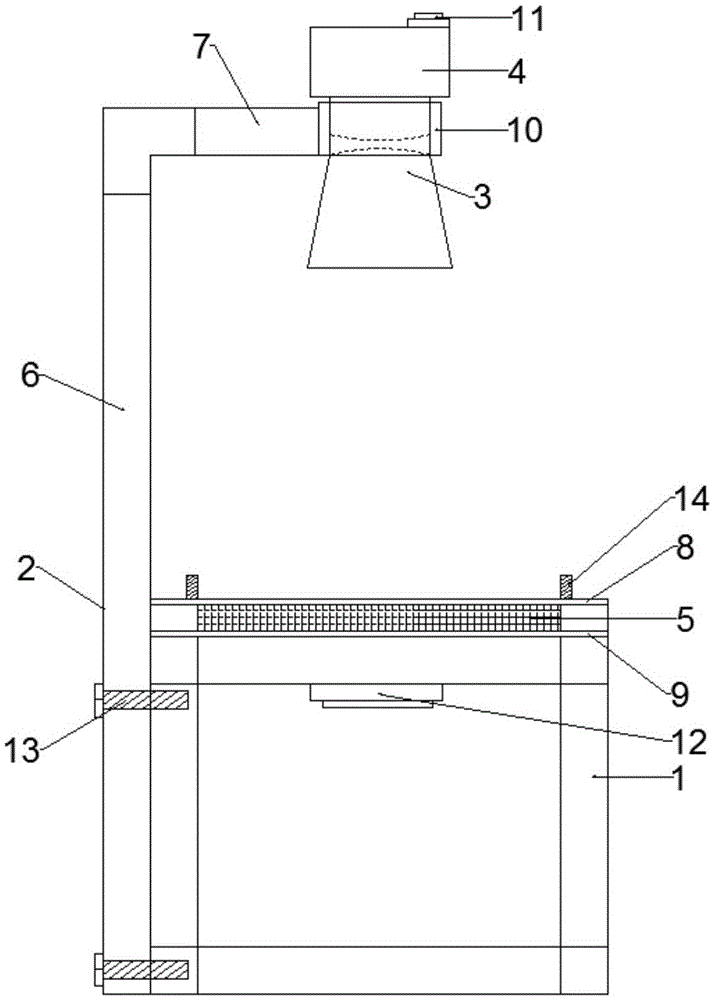

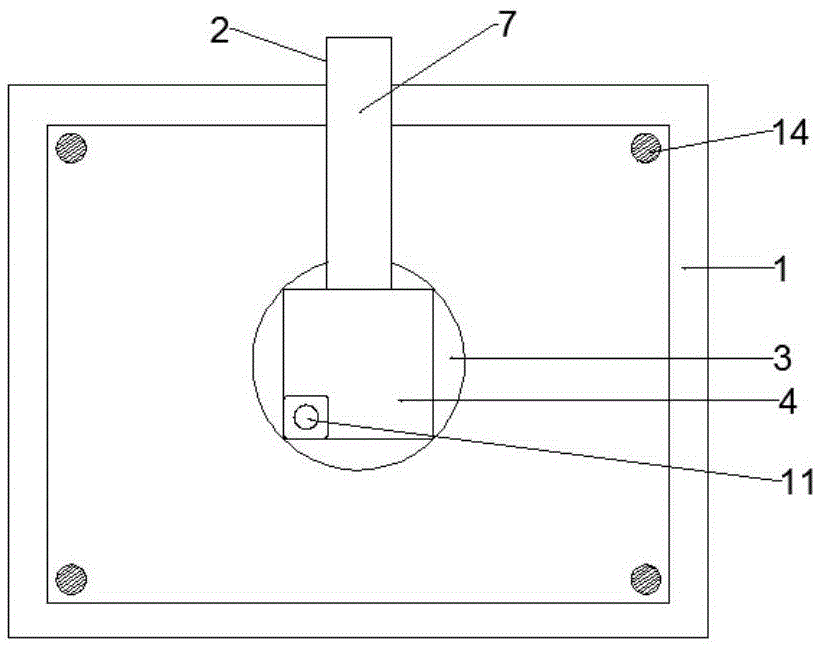

[0019] Embodiment 1: During inspection, a light-sensitive patch detection assembly includes a base 1, a bracket 2, a light source 4, a lens 3 and a photosensitive device 5, the bracket 2 includes a vertical bracket 6 and a horizontal bracket 7, and the top of the vertical bracket 6 is fixed Connect the horizontal bracket 7, the other end of the horizontal bracket 7 is fixedly connected to the lens holder 10, the lens holder 10 is fixedly provided with a lens 3, the upper surface of the lens 3 is fixedly provided with a light source 4, and the upper surface of the light source 4 is fixedly provided with a switch for controlling the light source 4 Device 11, the bottom end of the vertical support 6 is fixedly connected to the side wall of the base 1, the base 1 is a cuboid structure, the upper surface of the base 1 is respectively provided with a first loading platform 8 and a second loading platform 9, and the first loading platform 8 is located on Above the second stage 9, the ...

Embodiment 2

[0022] Embodiment 2: When not in use, a light-sensitive patch detection assembly includes a base 1, a bracket 2, a light source 4, a lens 3 and a photosensitive device 5, the bracket 2 includes a vertical bracket 6 and a horizontal bracket 7, and the top of the vertical bracket 6 Fixedly connected to the horizontal bracket 7, the other end of the horizontal bracket 7 is fixedly connected to the lens holder 10, the lens holder 10 is fixedly provided with a lens 3, the upper surface of the lens 3 is fixedly provided with a light source 4, and the upper surface of the light source 4 is fixedly provided with a control light source 4 The switch device 11, the bottom end of the vertical support 6 is fixedly connected to the side wall of the base 1, the base 1 is a cuboid structure, the upper surface of the base 1 is respectively provided with a first loading platform 8 and a second loading platform 9, the first loading platform 8 Located above the second stage 9, the first stage 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com