Klystron base

A technology of klystrons and tube holders, which is applied in the direction of discharge tubes, shells/containers of time-of-flight electron tubes, time-of-flight electron tubes, etc., and can solve the problem of cooling, placement of klystrons and magnets, and connection with power supplies Problems that cannot be solved quickly and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

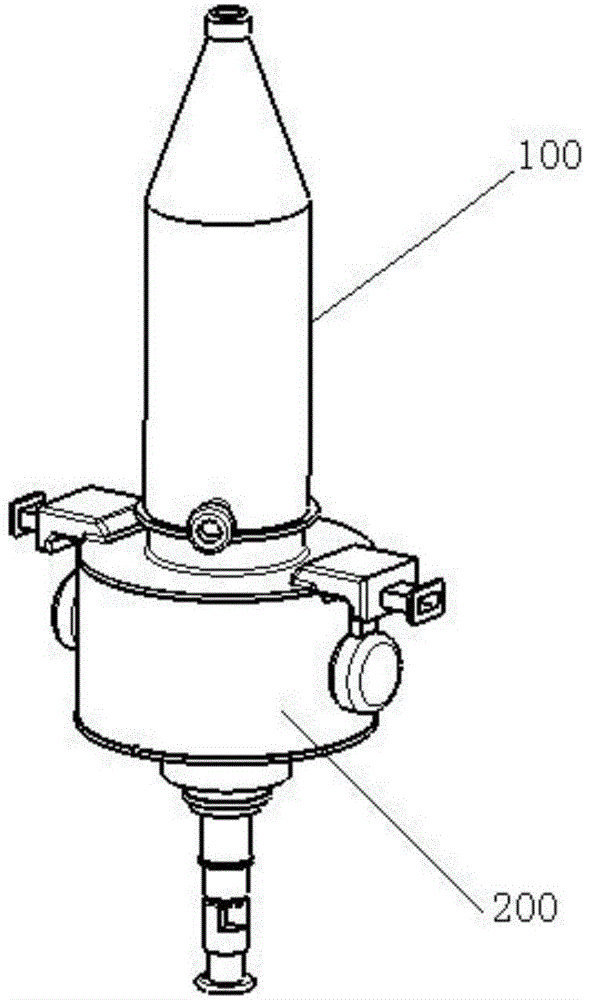

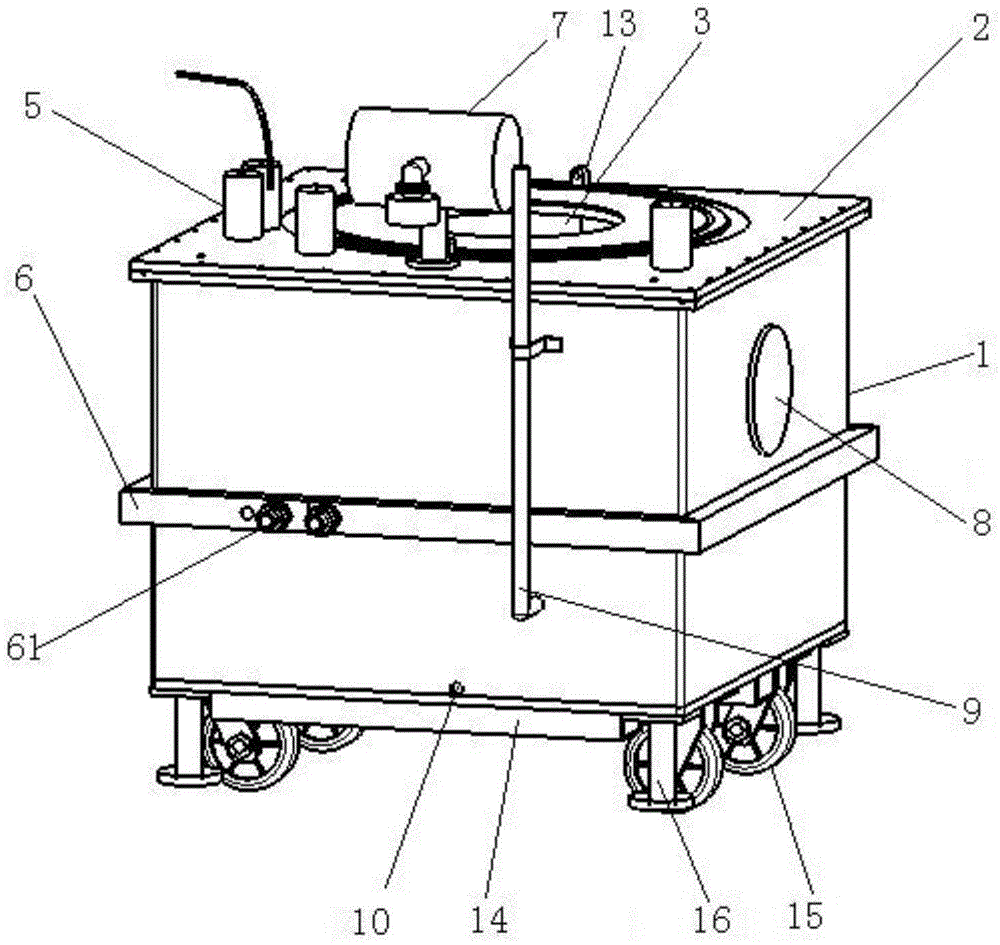

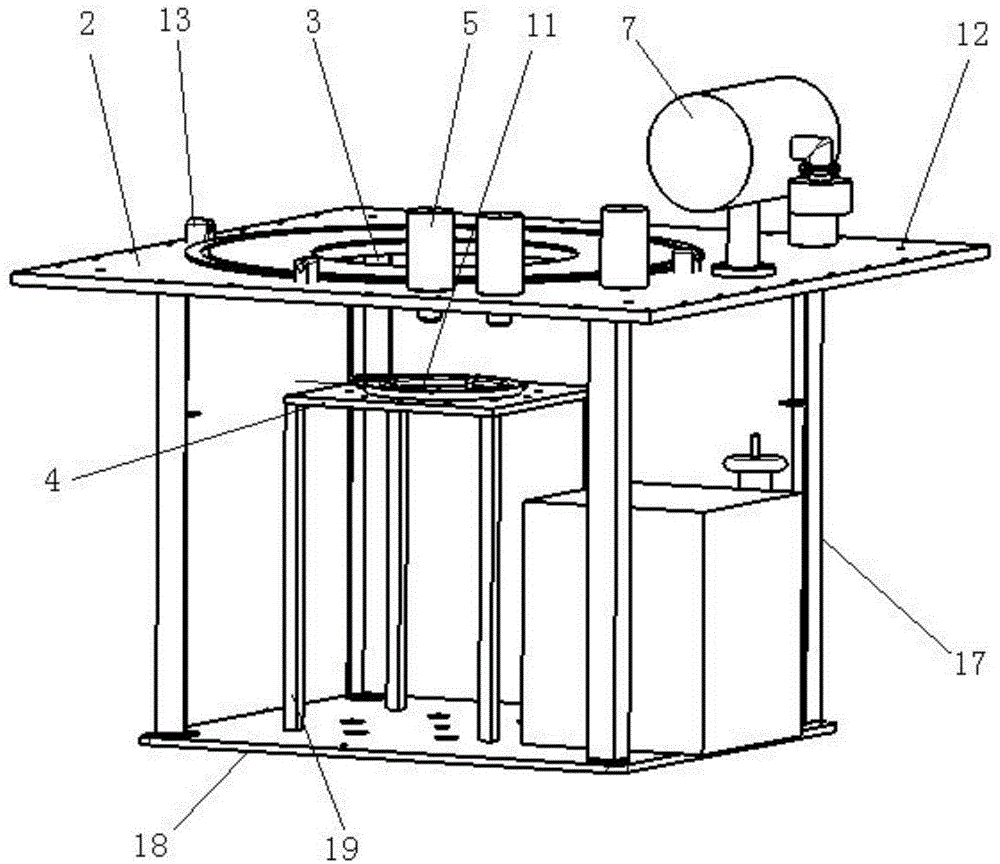

[0025] See attached figure 2 to attach Figure 5 , the klystron socket of the present invention includes an oil tank 1 for accommodating cooling oil, a top plate 2 is installed in a detachable seal on the top of the oil tank 1, and the end of the anode and cathode of the klystron 100 on the top plate 2 passes through Thereby the through hole 3 immersed in the cooling oil, the side wall of the through hole 3 can support the magnet 200 matched with the klystron 100, and the position of the anode after the klystron 100 is inserted into the oil tank 1 at the bottom of the top plate 2 is fixedly connected with the top plate 2 A klystron anode connector 4 is provided, and the position of the cathode corresponding to the klystron 100 inserted into the fuel tank 1 is fixedly connected to the top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com