Taper magnetic bearing switched reluctance motor and control method thereof

A technology of switched reluctance motor and reluctance motor, which is applied in the direction of electrical components, holding devices with magnetic attraction or thrust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

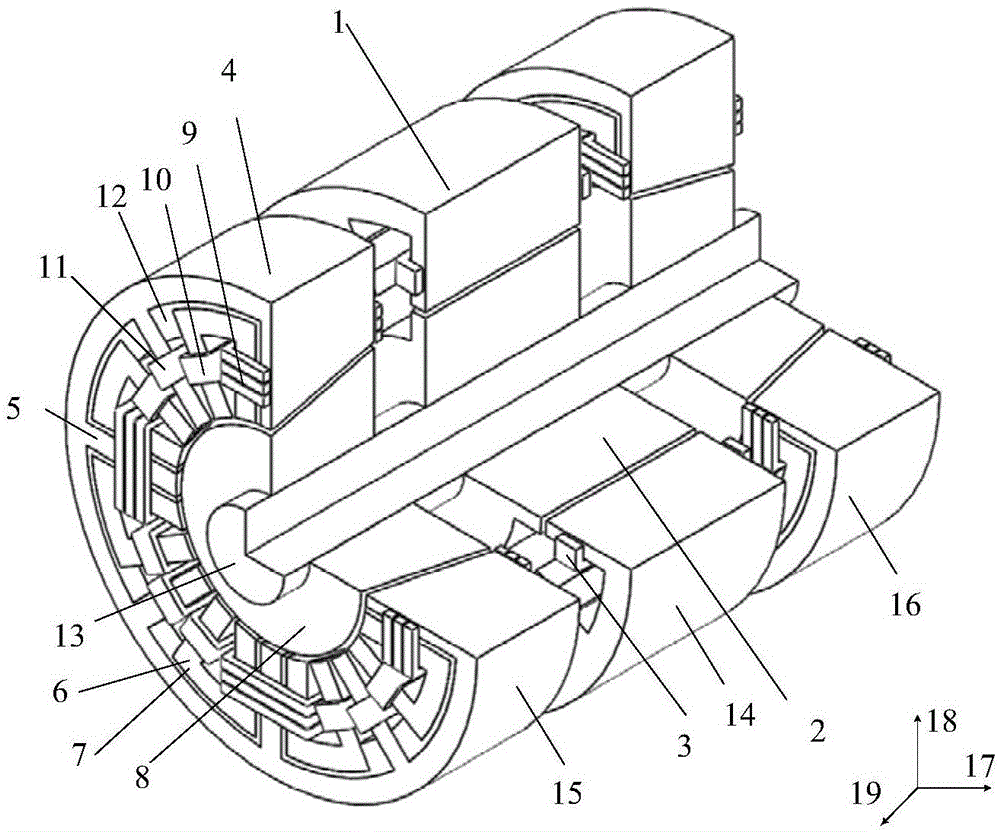

[0082] The technical scheme of a tapered magnetic bearing switched reluctance motor and its control method of the present invention will be described in detail below in conjunction with the accompanying drawings:

[0083] Such as figure 1 Shown is a three-dimensional structural schematic diagram of embodiment 1 of the tapered magnetic bearing switched reluctance motor of the present invention, wherein, 1 is the stator of the reluctance motor, 2 is the rotor of the reluctance motor, 3 is the winding of the reluctance motor, and 4 is the tapered stator , 5 is axial force stator, 6 is radial force stator, 7 is C-shaped structure, 8 is conical rotor, 9 is bias winding, 10 is radial suspension winding, 11 is axial suspension winding, 12 is non-conductive Magnetic components, 13 is a rotating shaft, 14 is a 12 / 8-pole switched reluctance motor, 15 is a tapered magnetic bearing I, and 16 is a tapered magnetic bearing II.

[0084] The tapered magnetic bearing switched reluctance motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com