Auxiliary mechanism for stretching steel rope

An auxiliary mechanism and steel rope technology, which is applied in the field of auxiliary mechanisms for drawing steel ropes, can solve the problems of low production efficiency, increased production cost, hidden safety hazards, etc., and achieves the effects of improving production efficiency, reducing labor costs, and avoiding disordered materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

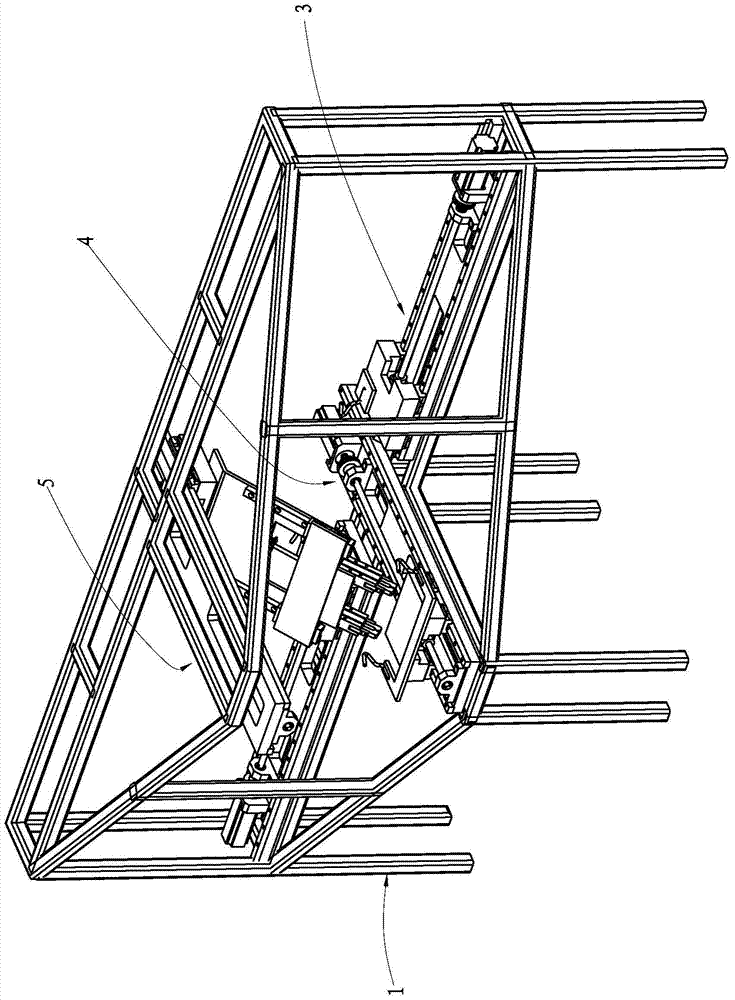

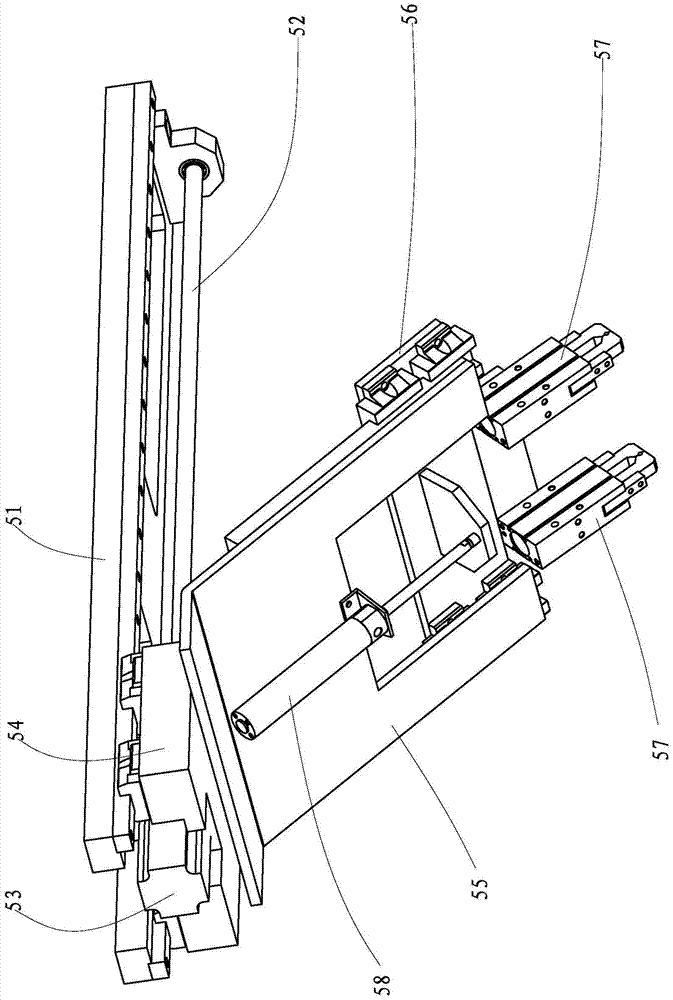

[0023] Such as figure 1 As shown, the present invention is an auxiliary mechanism for stretching steel ropes, including a frame 1, and the left and right sides of the frame 1 are provided with X-axis stretchers for straightening the steel rope 2 along the X-axis direction. Mechanism 3, on the frame 1 and between the two X-axis stretching mechanisms 3 is provided with a Y-axis stretching mechanism 4 for straightening the steel rope 2 along the Y-axis direction, on the frame 1 and located A catch mechanism 5 for clamping the middle of the steel rope 2 is provided above the Y-axis stretching mechanism 4 when the steel rope 2 is straightened. By controlling two sets of X-axis stretching mechanisms 3 and Y-axis stretching mechanisms 4, the steel rope 2 is straightened along the X-axis and Y-axis directions, and the two sets of X-axis stretching mechanisms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com