Tool holder for cutting insert

A technology for cutting blades and tool holders, which is applied to cutting blades, tools for lathes, accessories for tool holders, etc., and can solve problems such as high bending strength, uneven clamping characteristics of clamping segments, and complicated tool holder manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

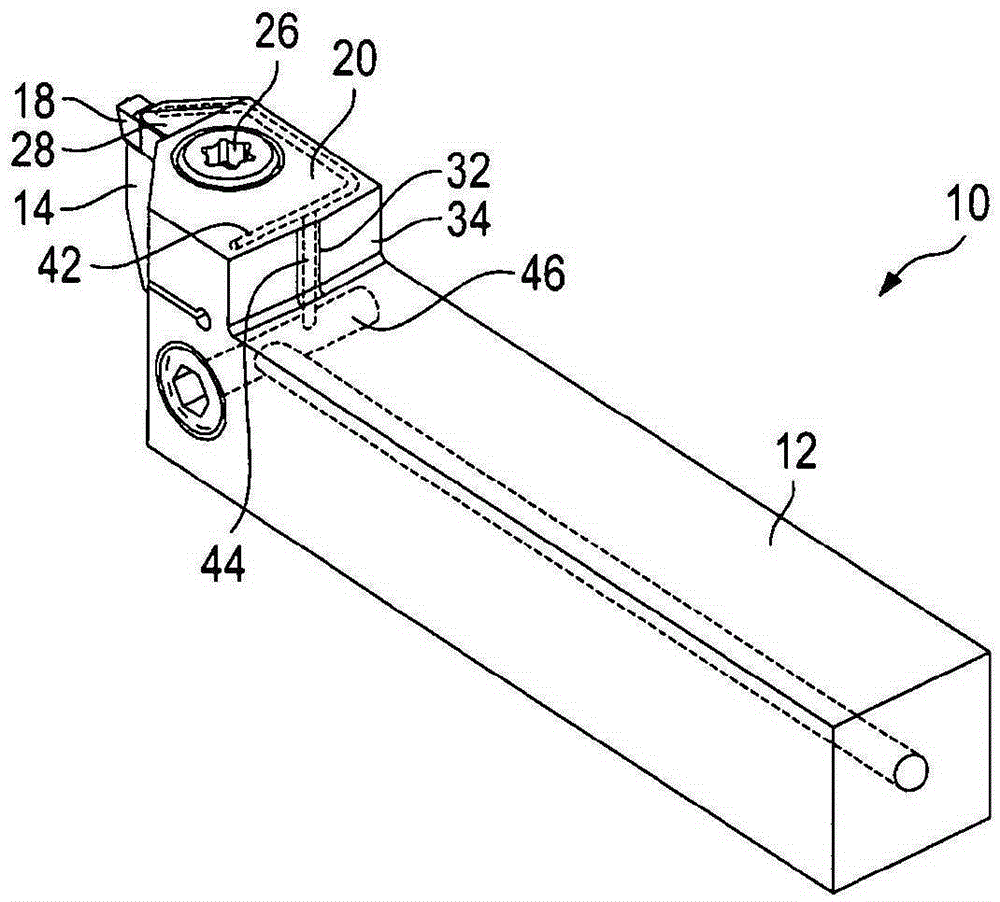

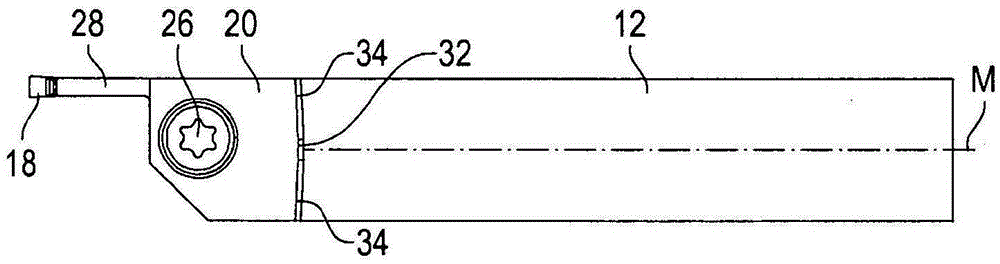

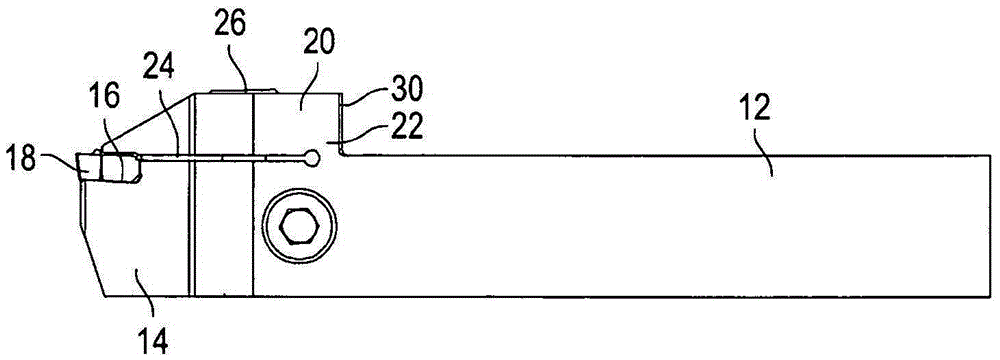

[0021] Figure 1 to Figure 5 A tool holder 10 having a handle 12 is shown. The tool holder 10 can be clamped into a machine tool (such as a lathe) by the handle 12.

[0022] At one end of the shank, referred to herein as the "front end", the shank is provided with a support section 14 on which a mounting seat 16 for the cutting insert 18 is provided. The cutting insert 18 is of the type that can be used especially for turning grooves and notches.

[0023] It is set here above the plane defined by the top side of the handle 12 (see image 3 The clamping section 20 of) is configured to clamp the cutting insert 18 into the mounting seat 16. The clamping section 20 is integrally joined to the handle 12 via the bending section 22. On the side of the curved section 22 facing the shank 12 (ie “upstream” thereof), the support section 14 and the clamping section 20 are separated by a gap 24.

[0024] A clamping element 26 is provided on the clamping section 20, and the clamping section 20 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap