Automatic production line for medical supplies

A technology for automated production lines and medical supplies, applied in the field of automated production lines for medical supplies, can solve problems such as product defect rate, large labor input, and increase production costs, and achieve the effects of reducing labor input, reducing labor costs, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

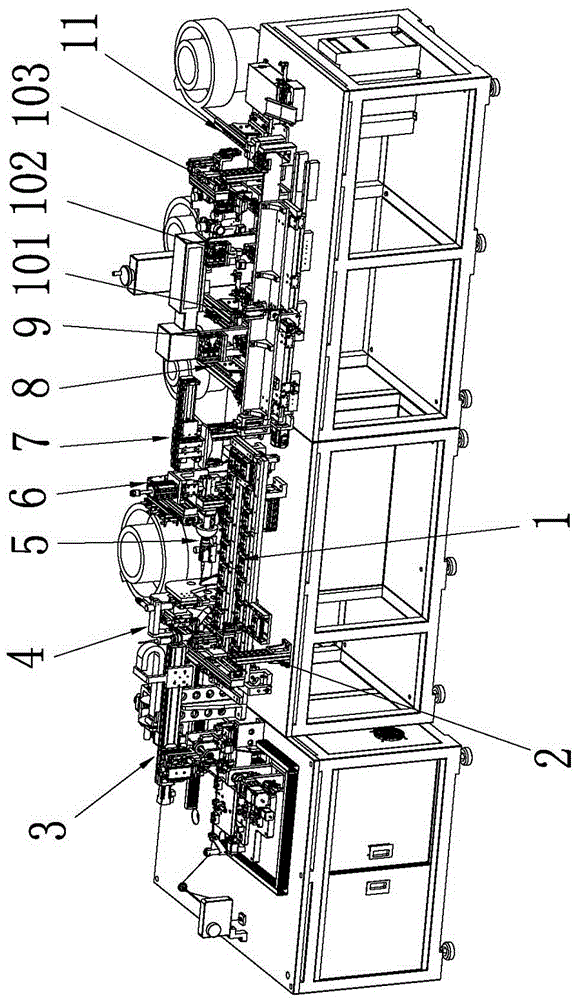

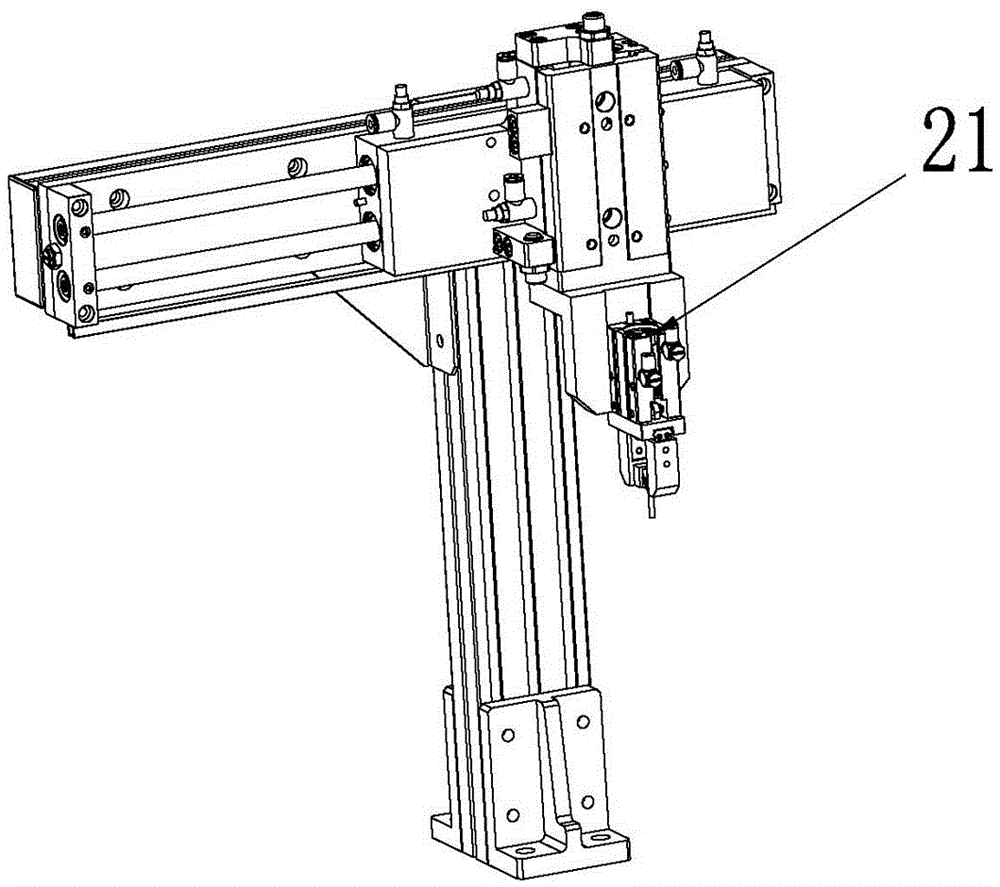

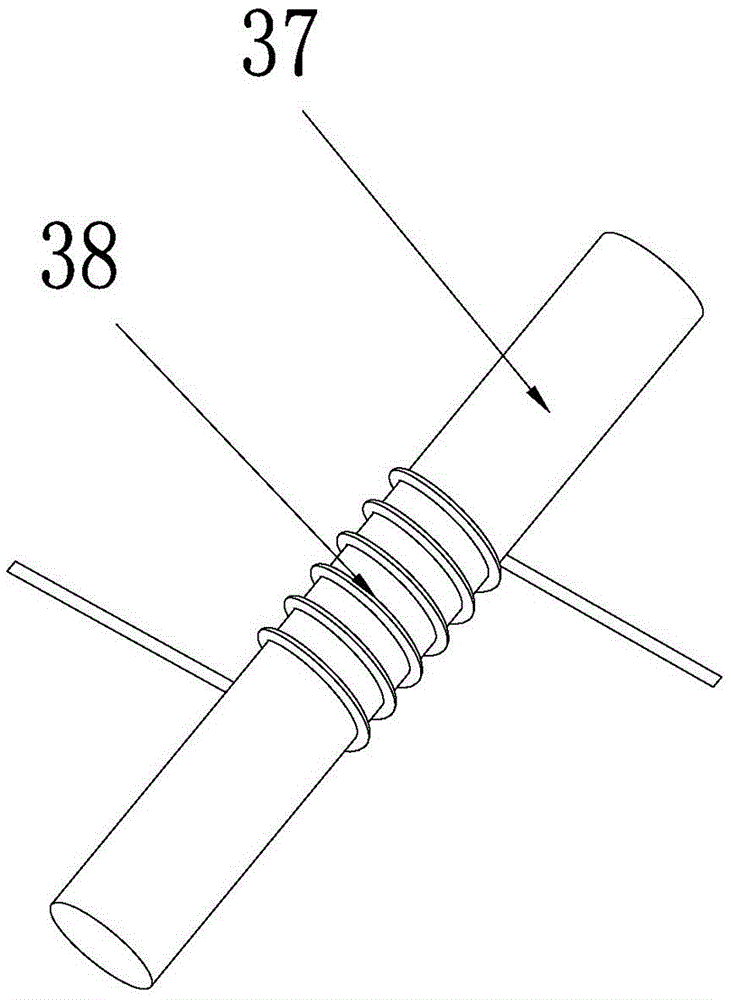

[0034] Attached below figure 1 to attach Figure 19 , and specific embodiments will further illustrate the present invention.

[0035] Such as figure 1As shown, an automatic production line for medical supplies includes a frame, the frame is provided with a conveyor 1, and the frame is also provided with a bracket feeding device 2 for placing the bracket on the conveyor 1, and the cotton thread assembly Cotton thread assembly feeding device 3 placed on the bracket, transparent cover feeding device 4 for installing the transparent cover on the bracket where the cotton thread assembly has been installed, the first detection device for detecting whether the steel wire of the product is in full contact with the metal sheet 5. The metal sheet pressing device for pressing the metal sheet on the transparent cover 6, the vacuum device for absorbing the dust inside the transparent cover 7, the bottom soft rubber feeding device for assembling the bottom soft rubber 8, for assembling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com