Automatic uninterrupted paper feeding mechanism for upper suction air feeding mechanism

A paper feeding and automatic technology, applied in the direction of object separation, pile separation, thin material handling, etc., can solve the problems of low work efficiency, high labor intensity, fast work speed, etc., to reduce labor intensity, liberate labor time, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

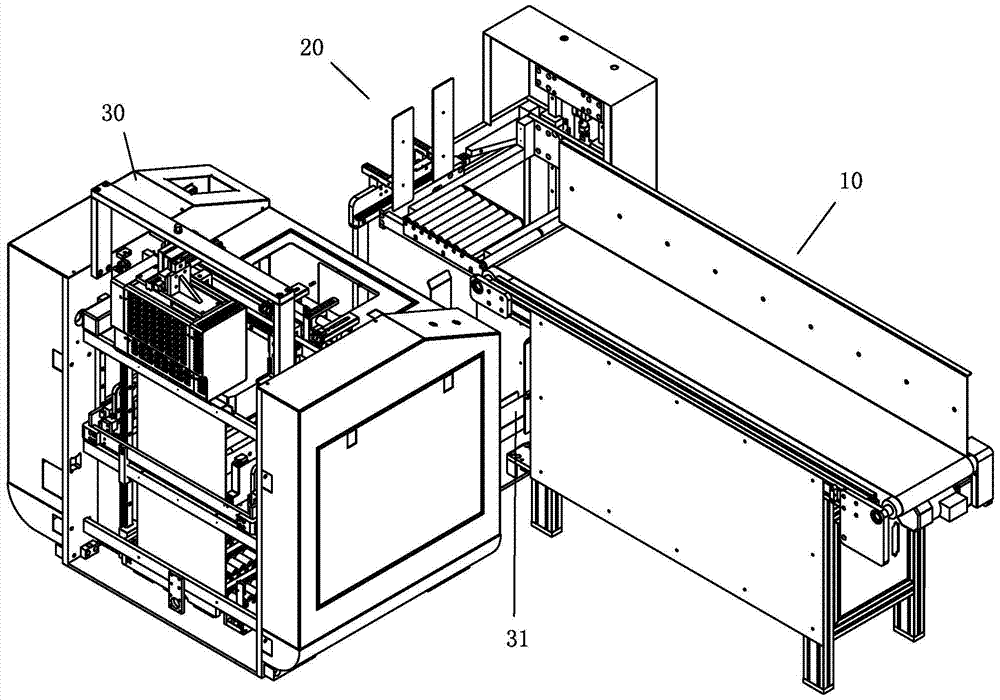

[0018] The automatic uninterrupted paper mechanism of the present invention is used for the upper suction air paper feeding mechanism in the product inspection machine (also known as the small-sheet printed product inspection machine). In this field, such as figure 1 , the upper suction air feeding mechanism 30 generally includes a pre-coded paper platform 31, the output end of the pre-coded paper platform 31 is set correspondingly to the input end of the uninterrupted paper feeding device (not marked in the figure), and the output of the uninterrupted paper feeding device The end is set corresponding to the input end of the upper suction air feeding device (not marked in the figure), so that the upper suction air feeding device outputs a single printed matter to the corresponding equipment behind it for subsequent quality inspection. The composition of the upper suction air paper feeding mechanism is well known to those skilled in the art, and its composition is not limited to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com