Mesh drive suction cup movement mechanism

A technology of motion mechanism and driving motor, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc. It can solve the problems of scratches on the surface of the sheet, manual handling of the sheet, and different spacing between the stacks of the sheets, so as to achieve the goal of moving Accurate displacement and rotation angle, satisfying fast warehousing and logistics, and improving the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Combine below Figure 1 to Figure 9 Embodiments of the present invention are described in detail.

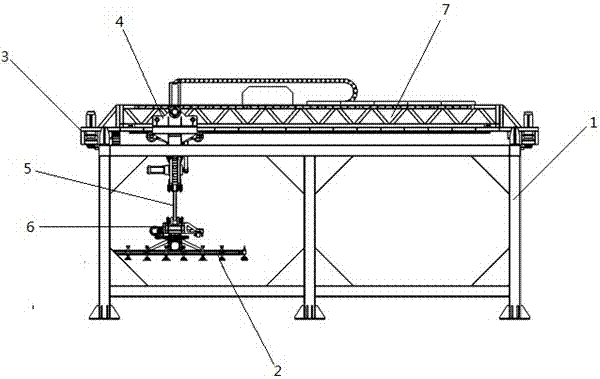

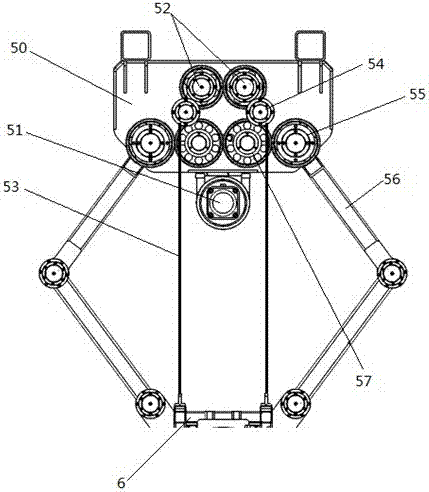

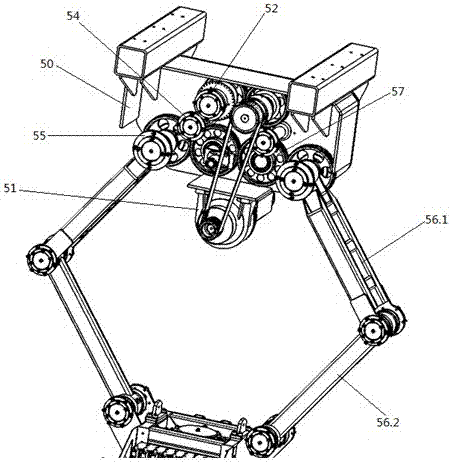

[0038] Such as figure 1 As shown, the meshing drive suction cup movement mechanism includes a rectangular parallelepiped frame-shaped frame 1 and a suction cup assembly 2 for absorbing sheet materials. The Y-axis power assembly 3 that moves power along the width direction of the frame 1, the X-axis power assembly 4 that provides the power for the suction cup assembly 2 to move along the length direction of the frame 1 in the frame 1, and the X-axis power assembly 4 that provides the suction cup assembly 2 in the frame 1. The Z-axis power assembly 5 of the lifting power in the height direction of the frame 1 and the P-axis rotation power assembly 6 that provides the horizontal rotation power of the suction cup assembly 2;

[0039] The top of the frame 1 is equipped with a beam 7 across the left and right sides of the frame 1, the X-axis power assembly 4 is mounted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com