A zero-discharge treatment method for steel pickling wastewater

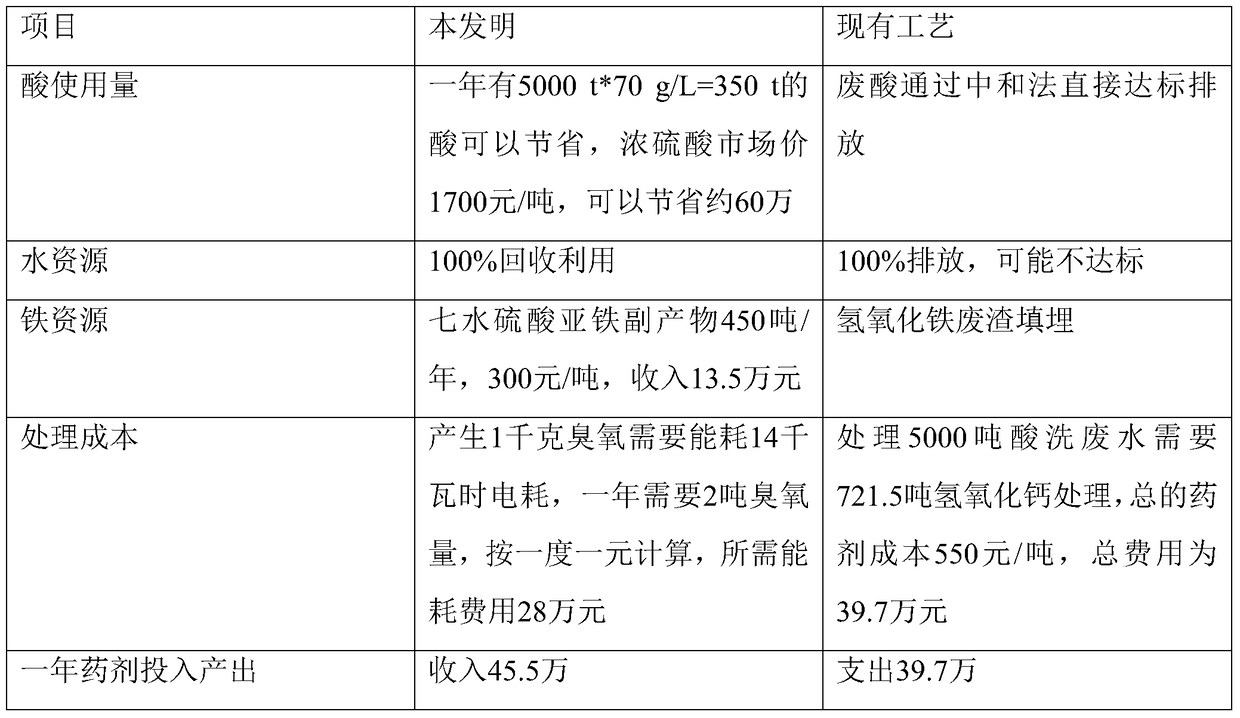

A technology for pickling wastewater and a treatment method, applied in the field of industrial wastewater treatment, can solve the problems of complex input equipment, unsuitable, high operating costs, and achieve the effects of reducing the amount of sulfuric acid used, avoiding waste, and achieving zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail with reference to specific examples.

[0028] 250mL of invalid iron and steel pickling water was used to carry out experimental demonstration through the above process scheme. The invalid iron and steel pickling water contained 280g / L of ferrous sulfate and 70g / L of sulfuric acid.

[0029] Put the steel pickling water in a large beaker through 3g / h of ozone, fully aerate for 1 hour, and stop the aeration and oxidation. At this time, the pickling water solution turns from green to brown; heat the pickling water to 40°C, The rust-containing iron block is pickled continuously until the pickling water fails, at this time, the solution turns from the original brownish yellow color to dark green; filter the solution through filter paper, cool to room temperature, and wait until the next day to obtain 10.6g of clean heptahydrate Ferrous sulfate crystals;

[0030] Add 0.15 mol of acid to the mother liquor after crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com