Compressor valve plate and compressor valve assembly

A compressor and valve plate technology, which is applied in the field of compressors, can solve the problems of uneven force on the suction valve plate of the compressor, reduce the sealing reliability of the valve group, and reduce the reliability of the compressor, so as to achieve uniform force and improve Operational reliability and effect of improving suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

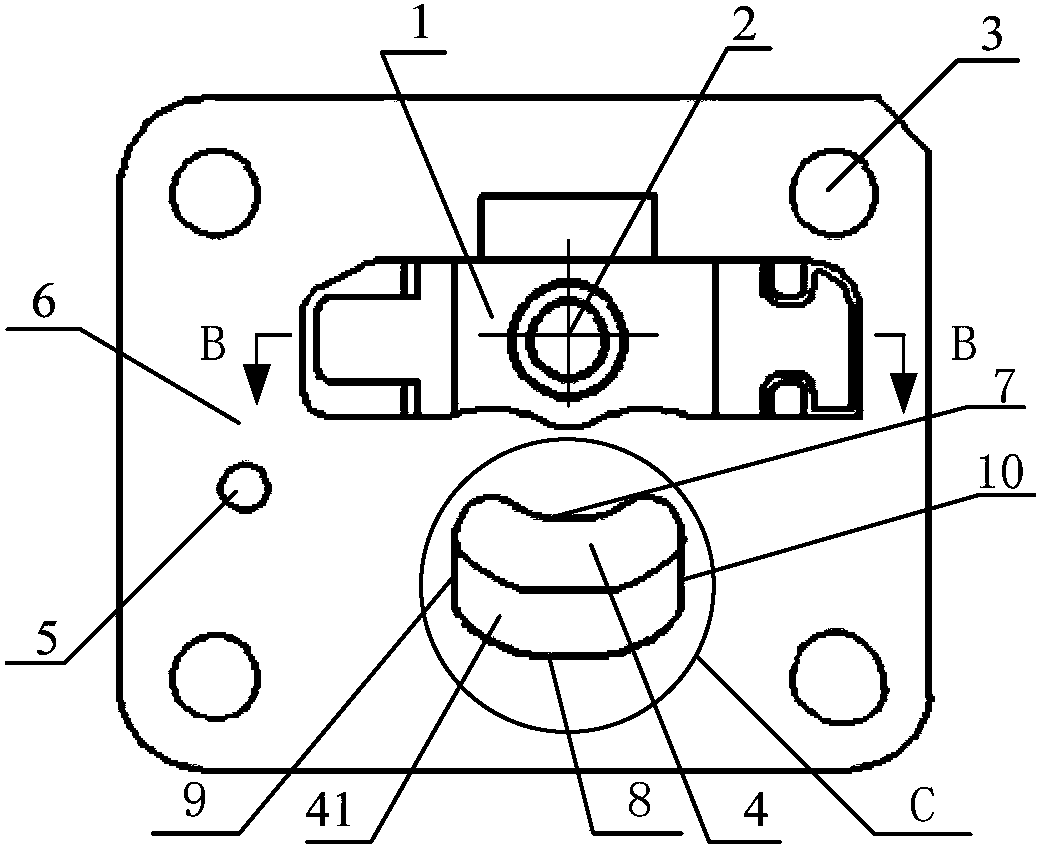

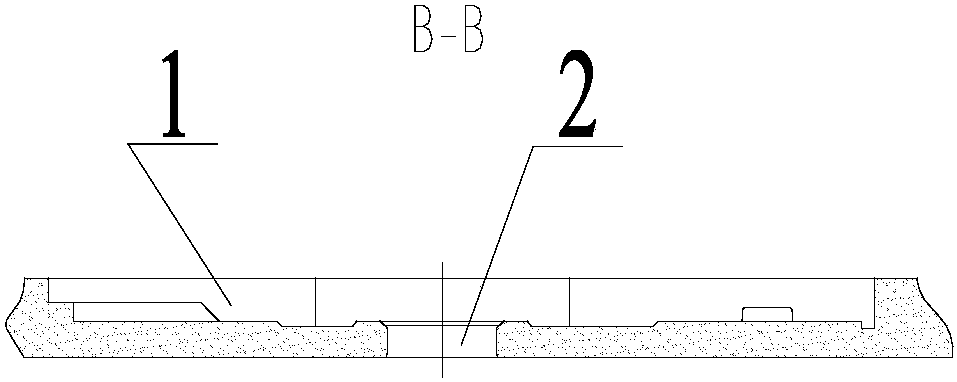

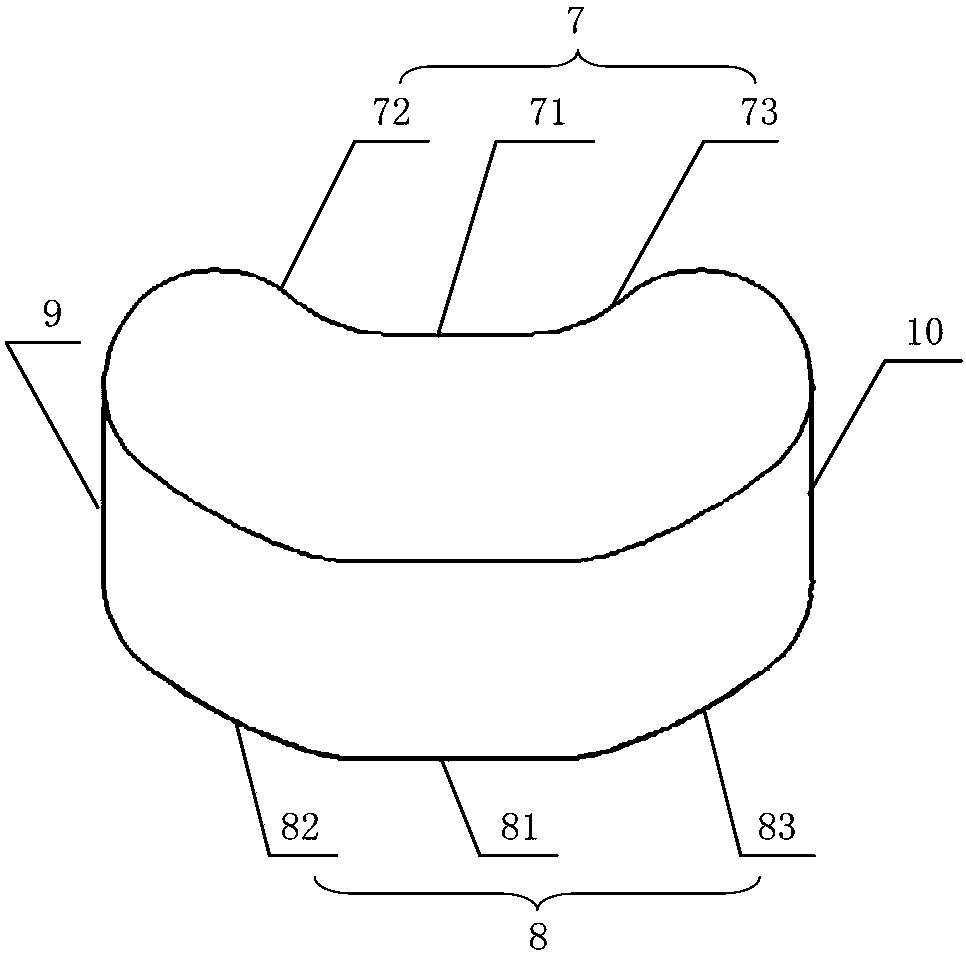

[0028] like Figure 1 to Figure 6 As shown, the present invention provides a compressor valve plate, including a valve plate body 6, a groove 1 is opened on the front of the valve plate body 6, an exhaust hole 2 is opened in the groove 1, and a valve plate body 6 is also opened. There is a suction hole 4, the contour line of the suction hole 4 includes a first curved segment 7 close to the exhaust hole 2 and a second curved segment 8 far away from the exhaust hole 2, the first curved segment 7 and the second curved segment 8 pass through The third circular arc 9 and the fourth circular arc 10 are connected, the first curved segment 7 and the second curved segment 8 both protrude in a direction away from the exhaust hole 2, and the first curved segment 7 includes a first transition straight segment in the middle 71, the second cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com