Novel angle aluminum structure

A new type of angle aluminum technology, applied in slender elements, building elements, heat exchange equipment, etc., can solve the problems of reducing the quality and application results of the angle aluminum, poor heat exchanger protection effect, and difficulty in ensuring the size of the angle aluminum. , to achieve the effect of simple structure, good mechanical stability and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

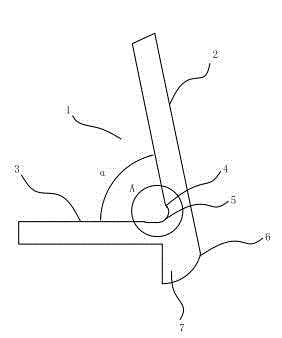

[0016] Such as figure 1 , figure 2 As shown, a new angle aluminum structure, the first panel 2 and the second panel 3 integrally form a bent plate main body 1, and an outwardly extending flange 7 is provided at the bent portion 6 of the bent plate main body 1 . Thinning grooves 5 are provided at the bends of the first panel 2 and the second panel 3 , and arc-shaped transition portions 4 are provided at both ends of the thinning groove 5 with the first panel 2 and the second panel 3 respectively. The thinning groove 5 is located inside the bend of the first panel 2 and the second panel 3 . The first panel 2 and the second panel 3 are bent to form an included angle α, and the included angle α is an acute angle. The second panel 3 and the flange 7 are perpendicular to each other, and the flange 7 is connected with the outer surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com