Sample testbed for EBSD (Electron Back-Scattered Diffraction) testing

A technology of sample testing and guide rails, which is applied in the direction of measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of backscattering area offset, inaccurate test results, easy to change image position, etc., to ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

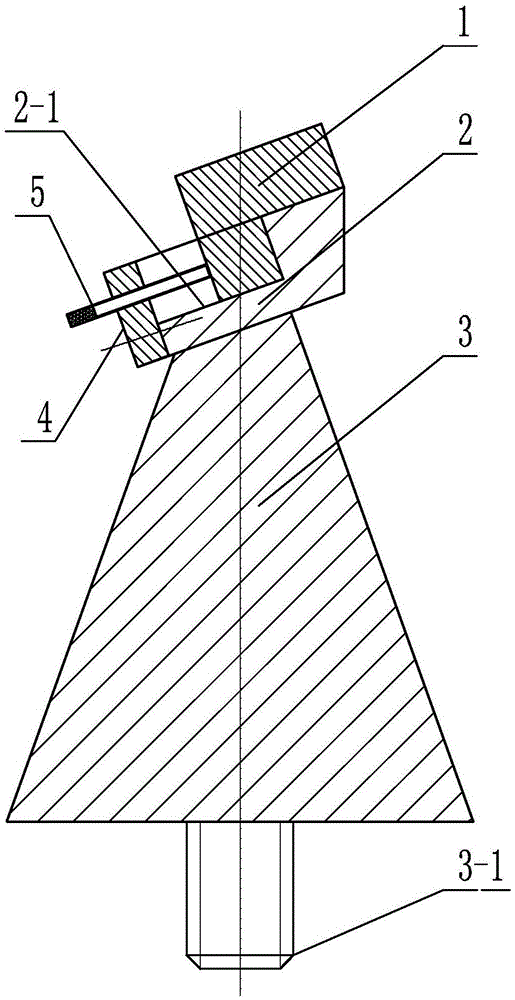

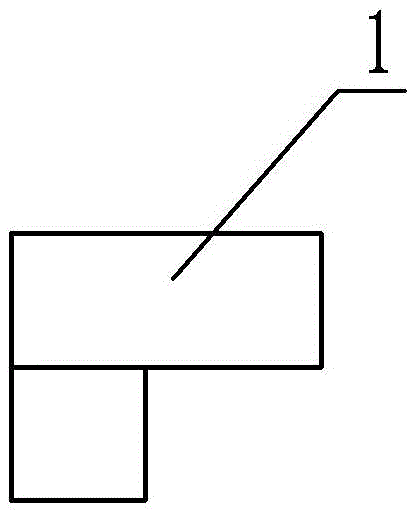

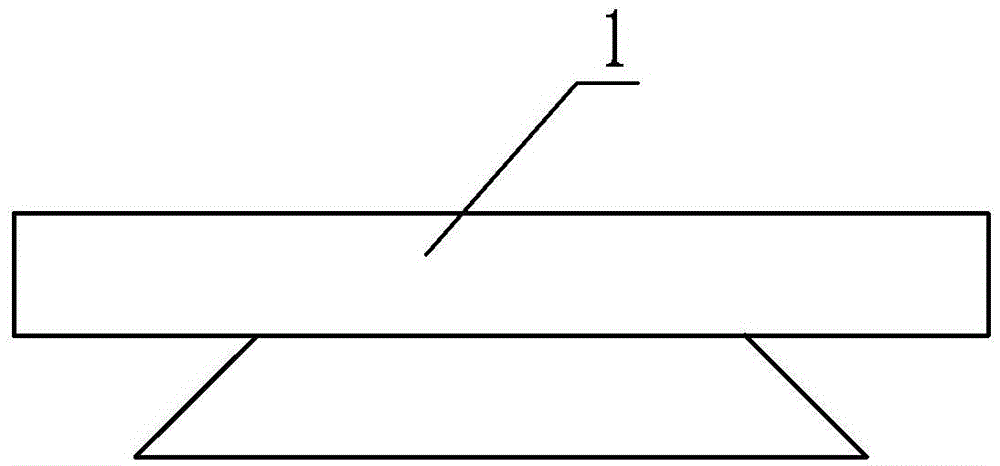

[0017] Specific implementation mode one: as Figure 1-7 As shown, the sample test bench for EBSD testing in this embodiment includes a slider 1, a guide rail 2, a base 3, a limit plate 4 and a jacking screw 5, the guide rail 2 is obliquely fixed on the upper end surface of the base 3, and the guide rail 2 Dovetail groove 2-1 is processed on the upper end surface of the guide rail 2, the angle between the length direction of the dovetail groove 2-1 of the guide rail 2 and the vertical direction is 70°, the upper part of the slider 1 is in the shape of a cuboid, and the lower part of the slider 1 It is a dovetail shape, the lower part of the slider 1 is located in the dovetail groove 2-1 of the guide rail 2 and the two are slidably connected, the angle between the upper end surface of the slider 1 and the vertical direction is 70°, and the lower part of the limit plate 4 It is detachably connected with the lower part of the guide rail 2 , and the middle part of the limiting plat...

specific Embodiment approach 2

[0019] Specific implementation mode two: as figure 1 , 5 As shown in and 6, the middle part of the lower end surface of the base 3 in this embodiment is provided with a stud 3-1. It is convenient to fix the sample test bench. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: as figure 1 As shown, in this embodiment, the lower part of the limiting plate 4 and the lower part of the guide rail 2 are detachably connected by two connecting bolts. With such a design, it is easy to disassemble and install. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com