Mechanism for continuous drilling of workpieces

A technology for workpieces and connecting rods, which is applied in the field of mechanisms for continuous drilling of workpieces. It can solve problems such as drill bit offset, uneven force on the drill bit, unqualified inclined holes, etc., and achieve the effect of ensuring reliability and avoiding motion interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

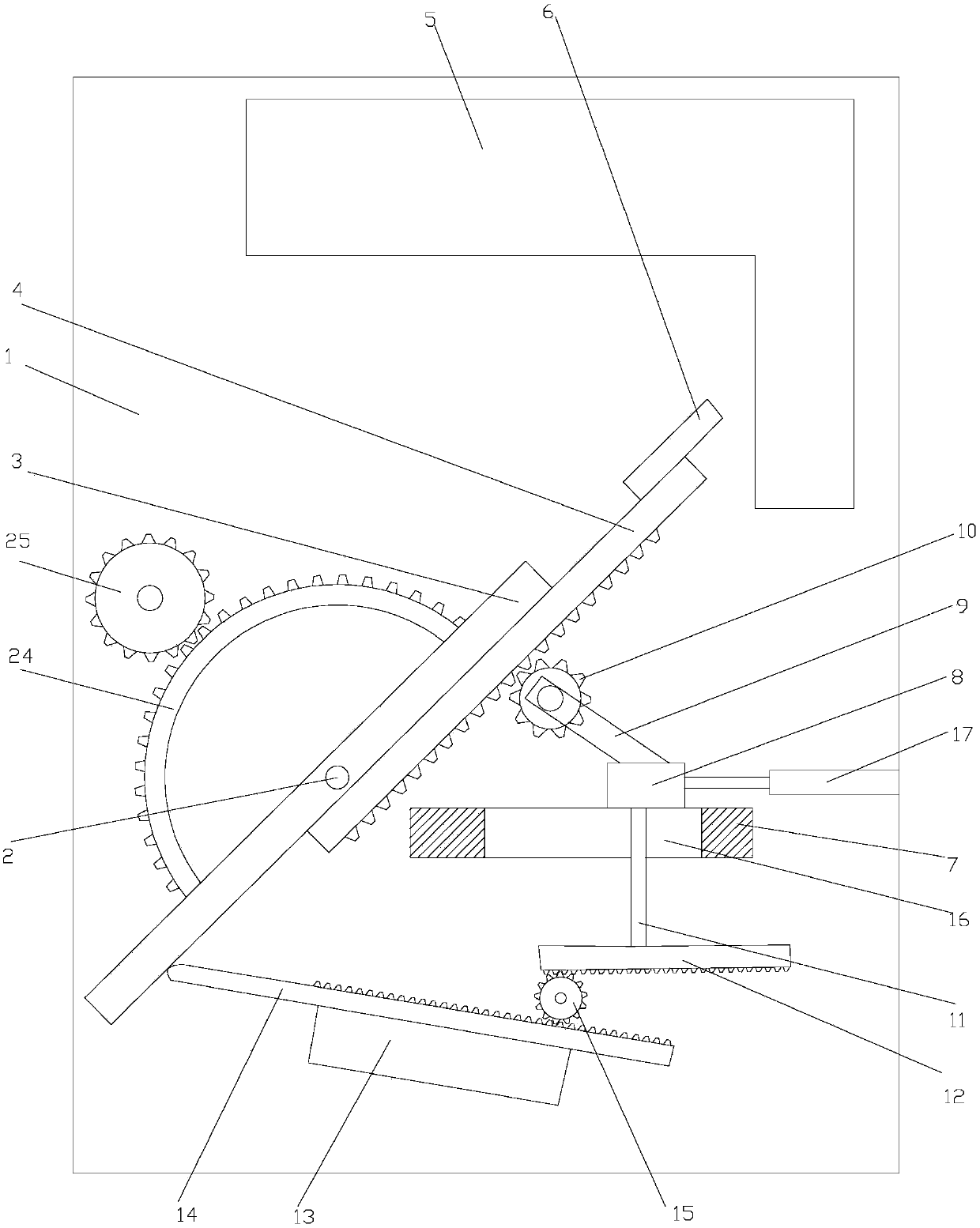

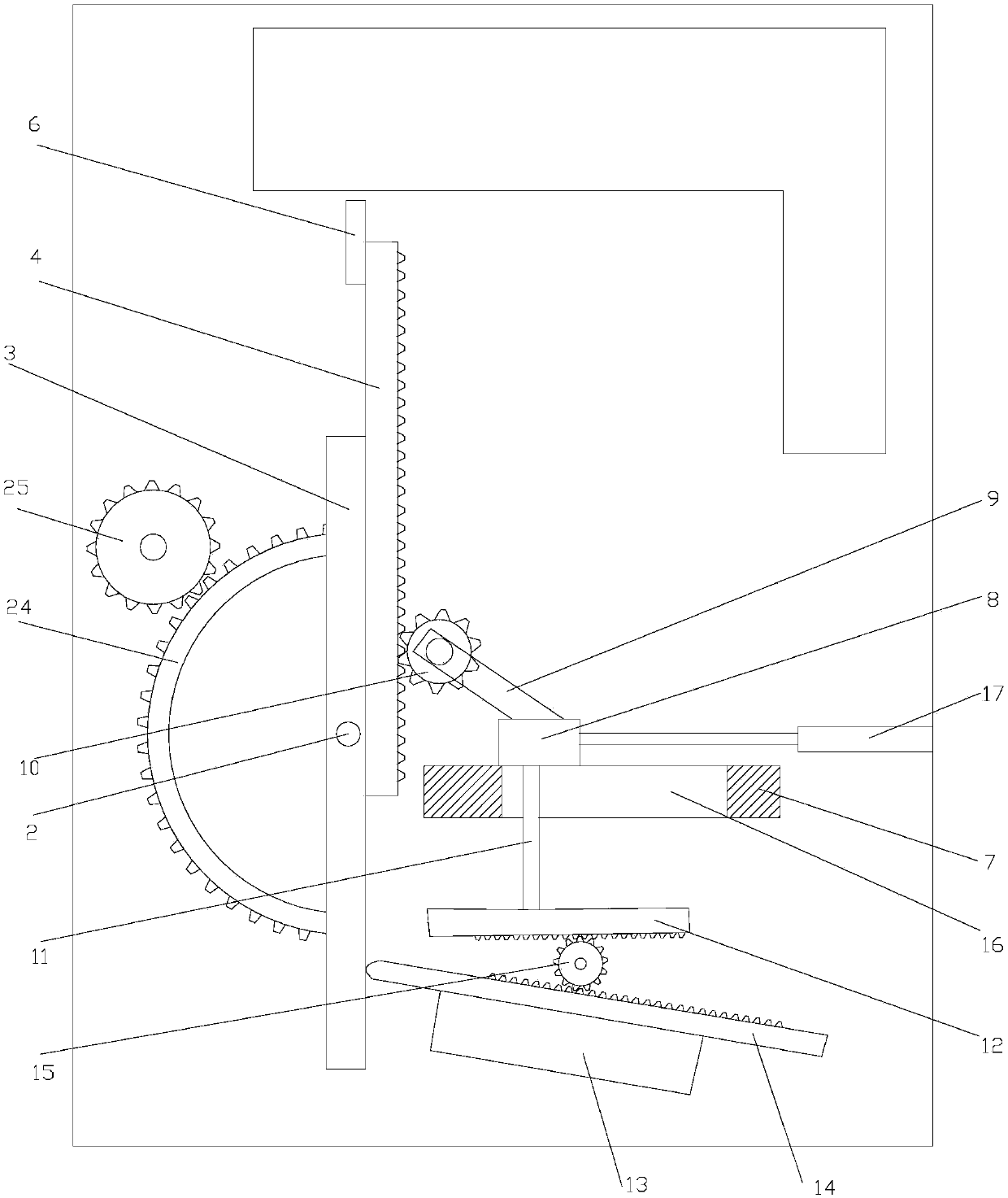

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] Working principle of the present invention:

[0017] First, the workpiece is placed on the base, and the workpiece is clamped and positioned by the fixture;

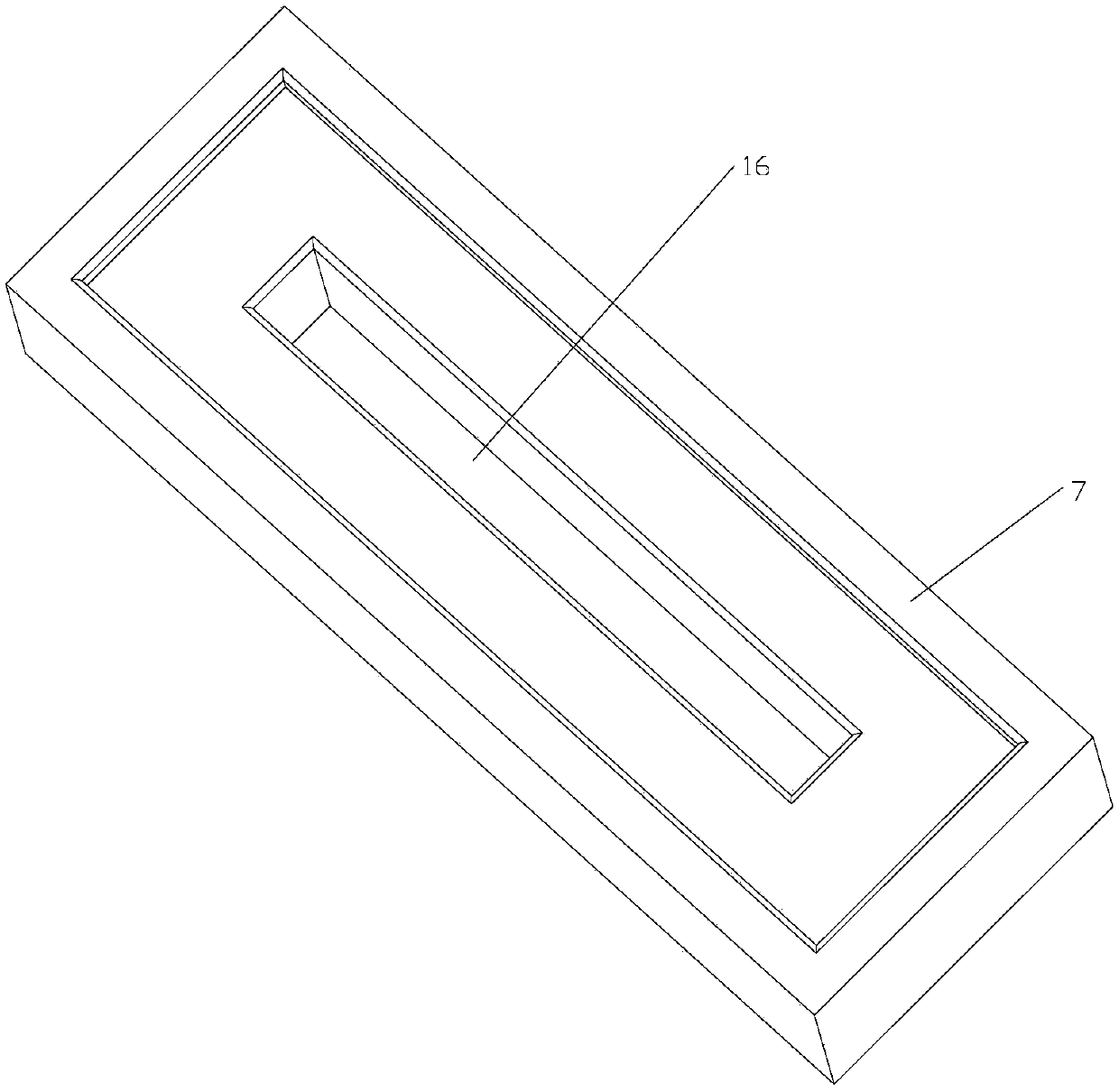

[0018] Then, the first cylinder works to drive the slider to move horizontally on the platform, such as figure 1 As shown, the first cylinder drives the slider to move to the left, and the slider pushes the first linear rack through the first gear at the upper end of the connecting rod, and then pushes the guide rod to rotate counterclockwise around the rotating shaft. When the slider moves to the left, The second linear rack also moves to the left, and the second linear rack drives the third linear rack to move to the right through the meshing transmission of the second gear, and the left end of the third linear rack is always against the lower end of the guide rod, That is to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com