A method to eliminate the first ten effect of flash annealing machine

An annealing and effect technology, applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of waste of production capacity and human resources, increase of production costs, etc., and achieve the goals of avoiding waste, improving product yield, and stabilizing the process environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

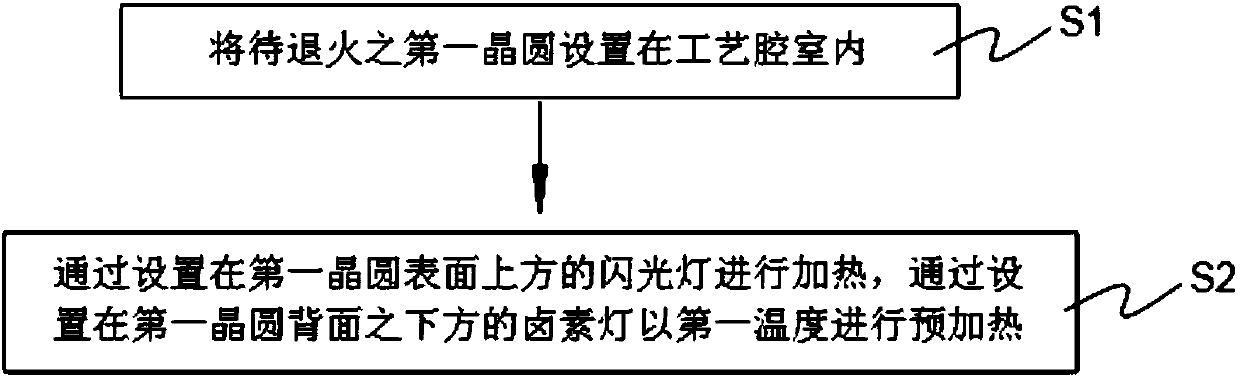

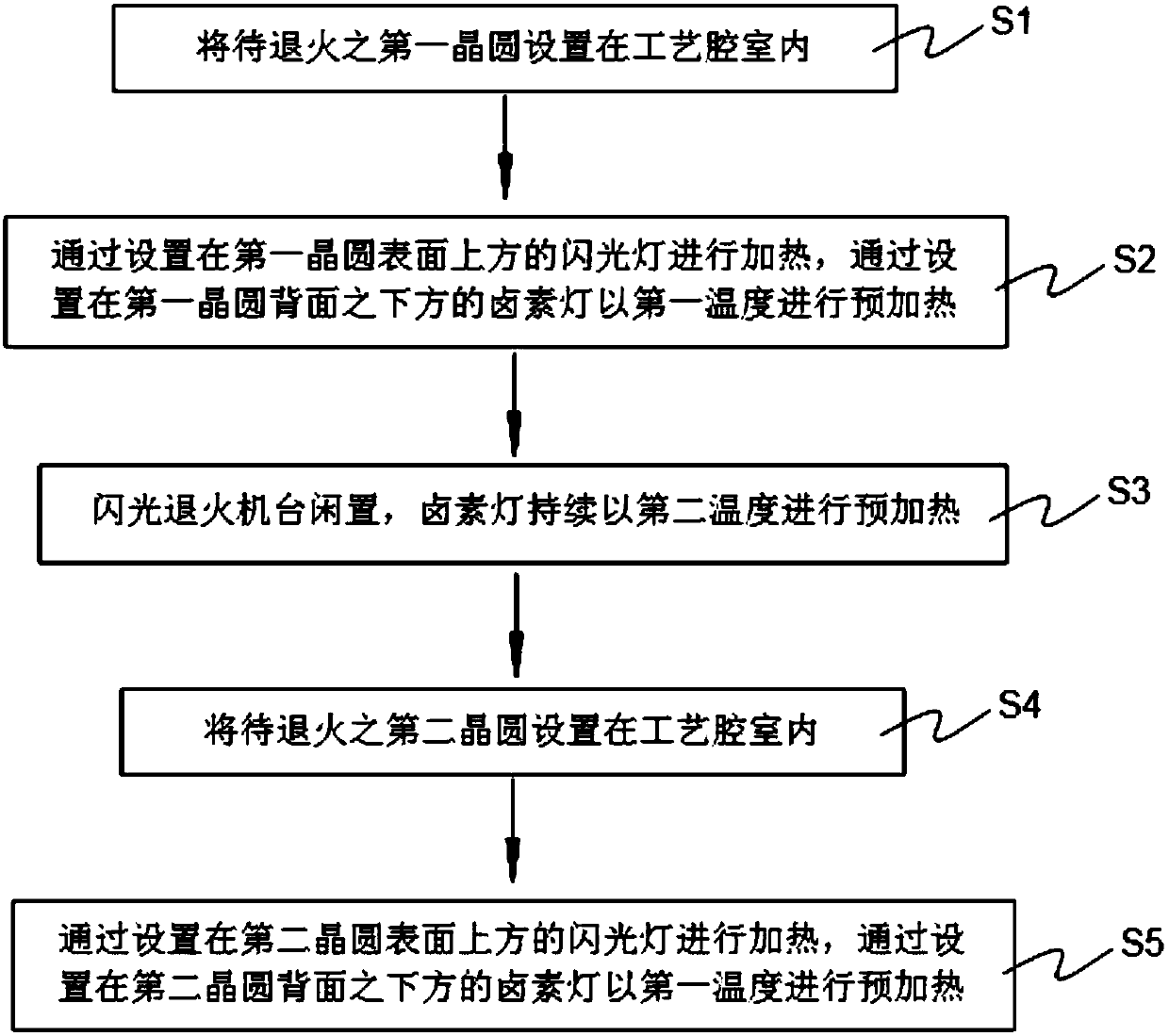

[0027] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0028] After the traditional ion implantation process, an annealing process is usually used to activate the impurities and repair the damage caused by the ion implantation to the substrate wafer. However, as the feature size of silicon-based devices is reduced to 40 / 28 nanometers, the integration and complexity are enhanced, especially the ultra-shallow junction has stricter control over the diffusion of dopant elements, and only traditional uniform temperature annealing (second level) And the peak annealing (about 1000 milliseconds) can no longer meet the requirements of thermal budget (Thermal Budget), thus affecting the performance of CMOS devices.

[0029] In order to reduce the diffusion of impurities while activating them, more adv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com