Drug stent and balloon spraying equipment

A technology of spraying equipment and balloons, which is applied to stents, spraying devices, balloon-shaped catheters, etc., can solve the problems of inability to guarantee the quality of spraying, high requirements for spraying environment, destruction of spraying and spraying environment, etc. Stable, avoid drug waste, ensure the effect of spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

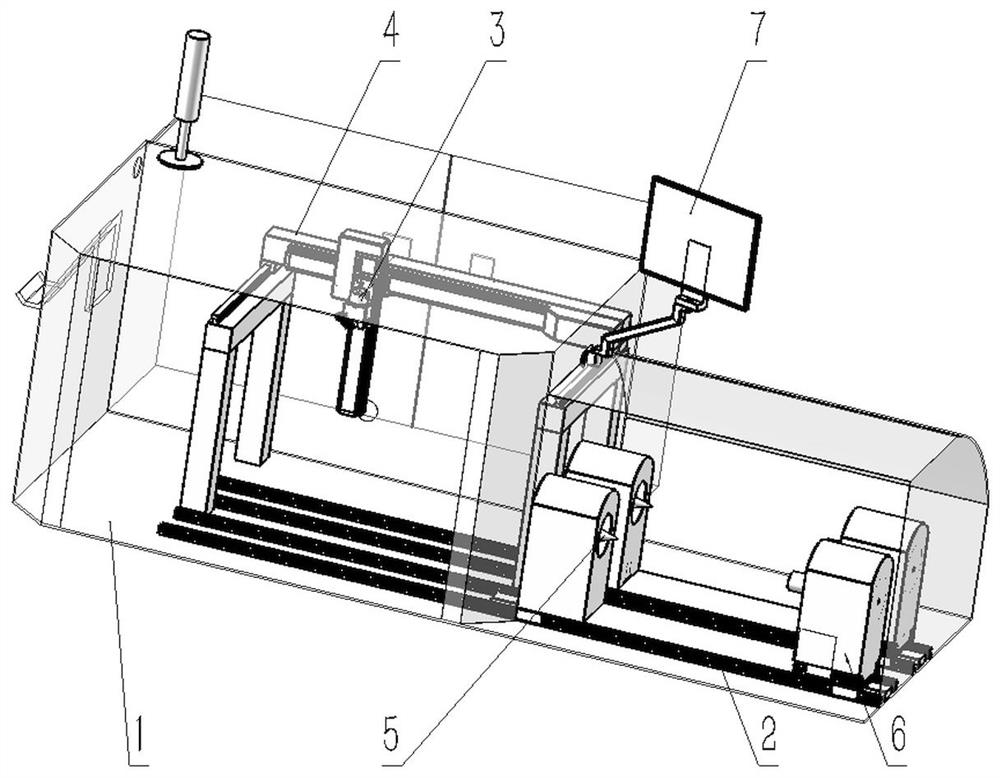

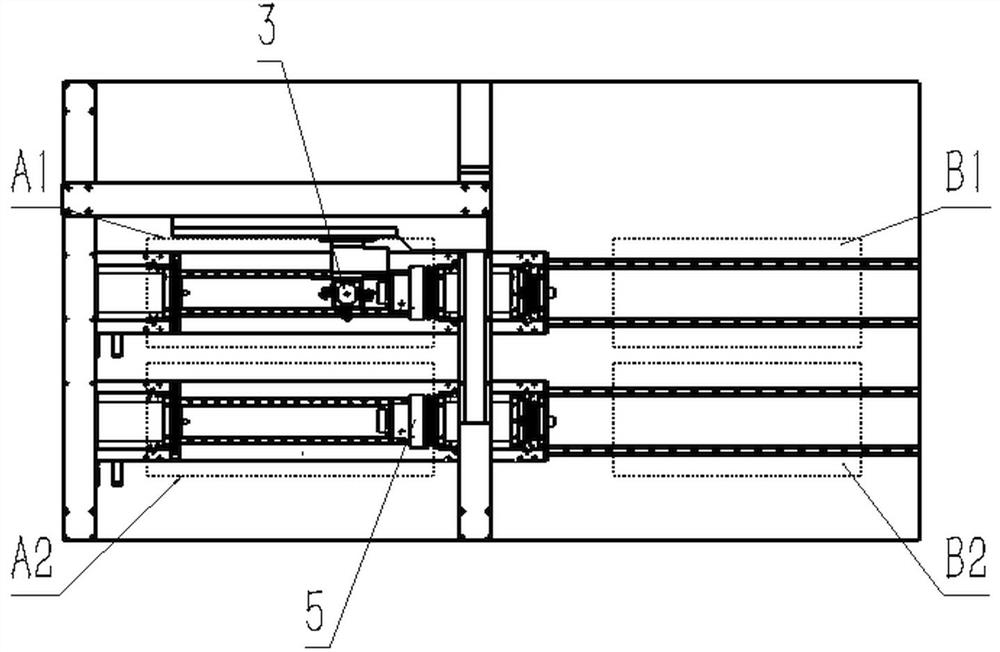

[0034] Such as figure 1 and figure 2 As shown, the overall structure of a drug stent and balloon spraying equipment includes a spraying chamber 1 , an ultrasonic nozzle 3 , a nozzle moving unit 4 , a clamping area 2 , a clamp 5 , and a clamp moving unit 6 .

[0035] The spray booth 1 is isolated from the external environment, and there are multiple processing positions in the spray booth 1 . In the case of this embodiment, there are processing position A1 and processing position A2. The shell of the spray booth 1 is made of light and thin aluminum material for surface anodic oxidation treatment, which is milky white, and other common metal or non-metal shells can also be used.

[0036] The clamping area 2 is arranged in the adjacent outer area of the spray booth 1 and has a clamping position. There may be one clamping position, or there may be a plurality of clamping positions. In the case of this embodiment, there are clamping position B1 and clamping position B2.

[0...

Embodiment 2

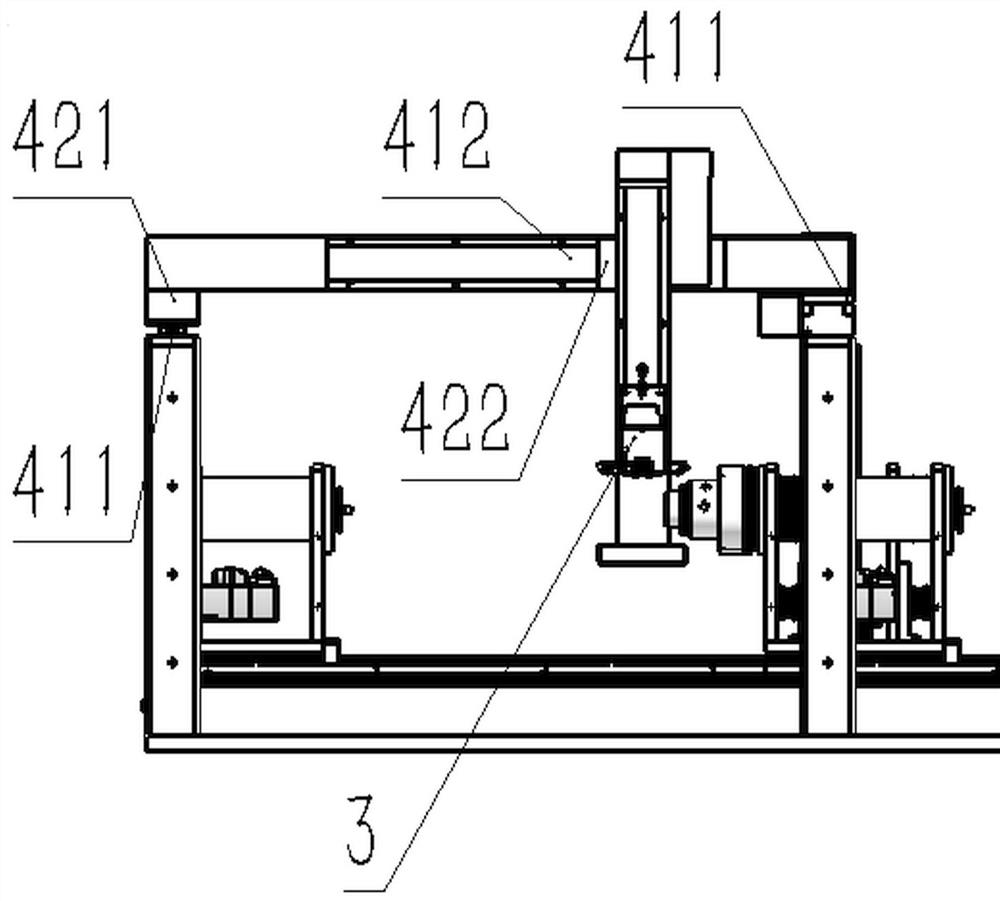

[0041] Such as image 3 As shown, the nozzle moving unit 4 includes two first guide rails 411, which are radially arranged in the spraying chamber 1 relative to the workpiece, and the two first guide rails 411 are parallel to each other; The workpiece moves radially; the second guide rail 412 is fixedly connected with the first slider 421 ; the ultrasonic nozzle 3 is fixedly connected with the second slider 422 and can move axially along the second guide rail 412 . In this embodiment, two first guide rails 411 parallel to each other are provided to improve the precision of movement, thereby improving the precision of drug application process and product quality, and only one first guide rail 411 may be provided.

[0042] The first sliding block 421 can slide on the first guide rail 411 to move the ultrasonic nozzle 3 between the processing position A1 and the processing position A2, thereby completing the station switching movement.

[0043]The second slider 422 can slide on ...

Embodiment 3

[0045] Such as Figure 4 As shown, in this embodiment, since the workpiece turning mechanism 63 is provided on the fixture moving unit 6 , the workpiece can be rotated in the circumferential direction, and the ultrasonic nozzle 3 does not need to move toward the workpiece and rotate around the workpiece axis. Corresponding mechanisms are therefore omitted in the nozzle displacement unit 4 . If the workpiece turning mechanism 63 is not provided on the fixture moving unit 6 , it is enough to design and add a mechanism in the nozzle moving unit 4 that can make the ultrasonic nozzle 3 move toward the workpiece and rotate around the workpiece.

[0046] Above, the nozzle moving unit of one embodiment constituted by guide rails and sliders has been described, but the nozzle moving unit can also be formed in other ways, for example, other embodiments such as threaded rods, rotating mechanisms, and mechanical arms can be used, as long as It only needs to enable the ultrasonic nozzle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com