A low-rank pulverized coal continuous dry distillation process and device

A pulverized coal and dry distillation technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of environmental pollution, ineffective sealing, dust and gas leakage, etc., to ensure the stability of the process environment and prevent excessive pressure. , the effect of preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

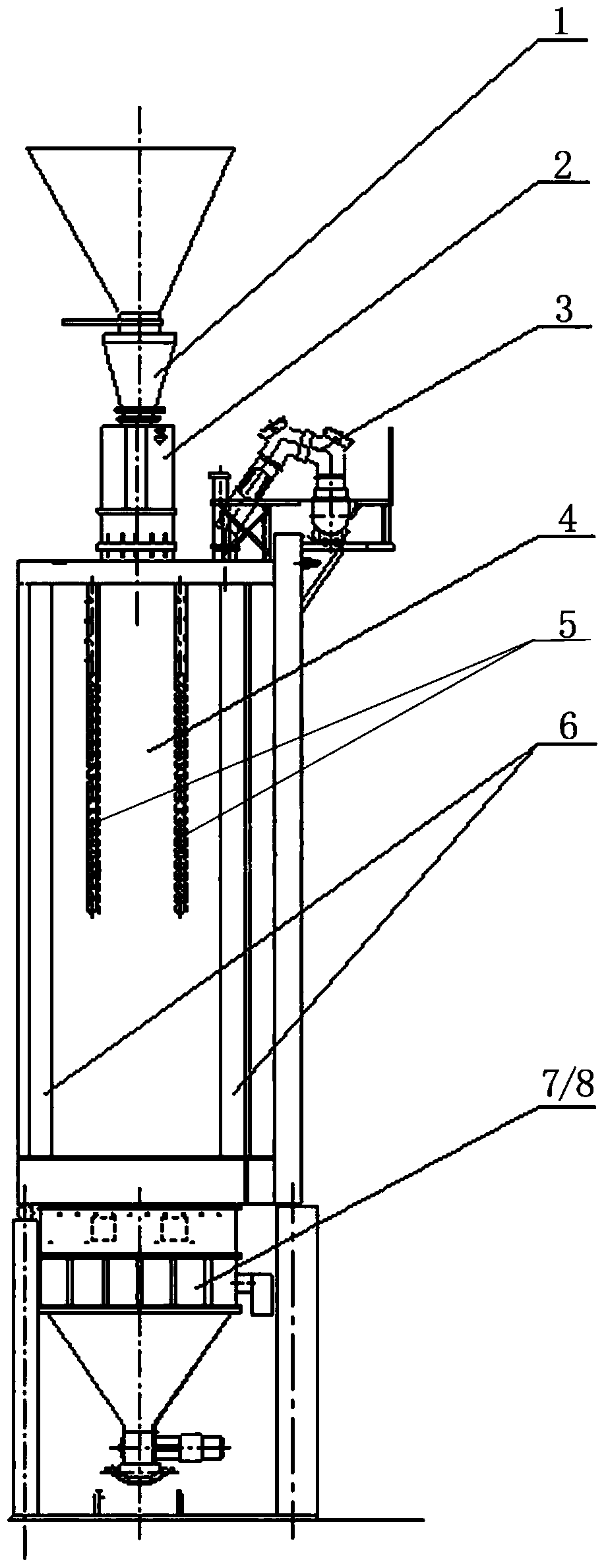

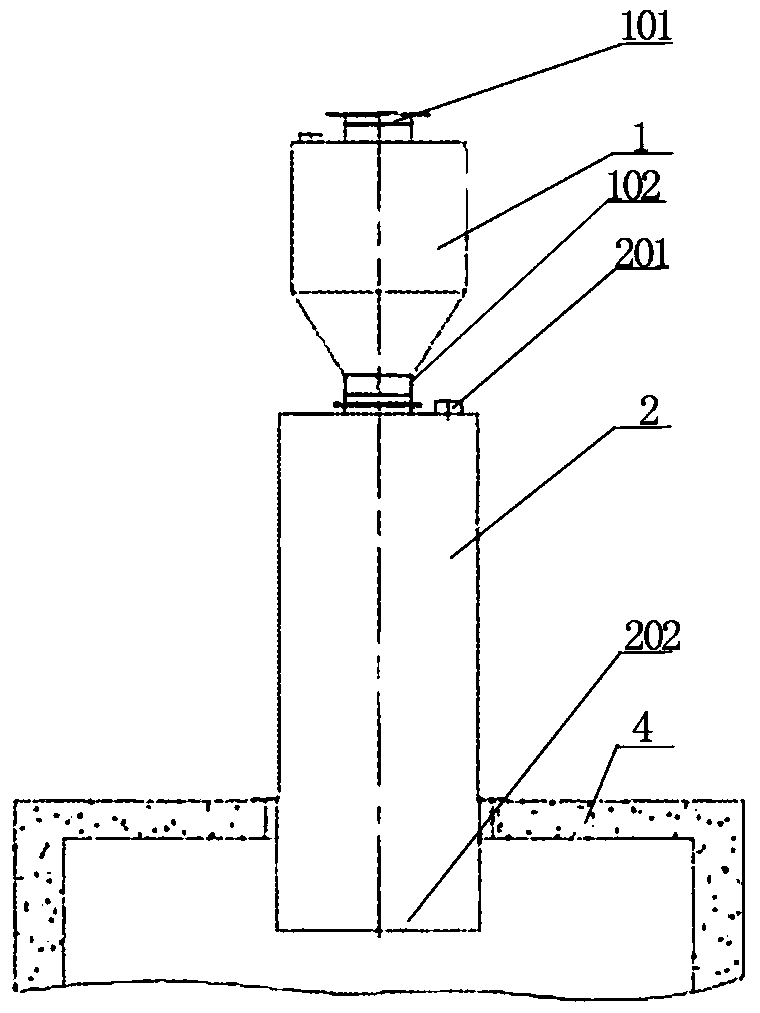

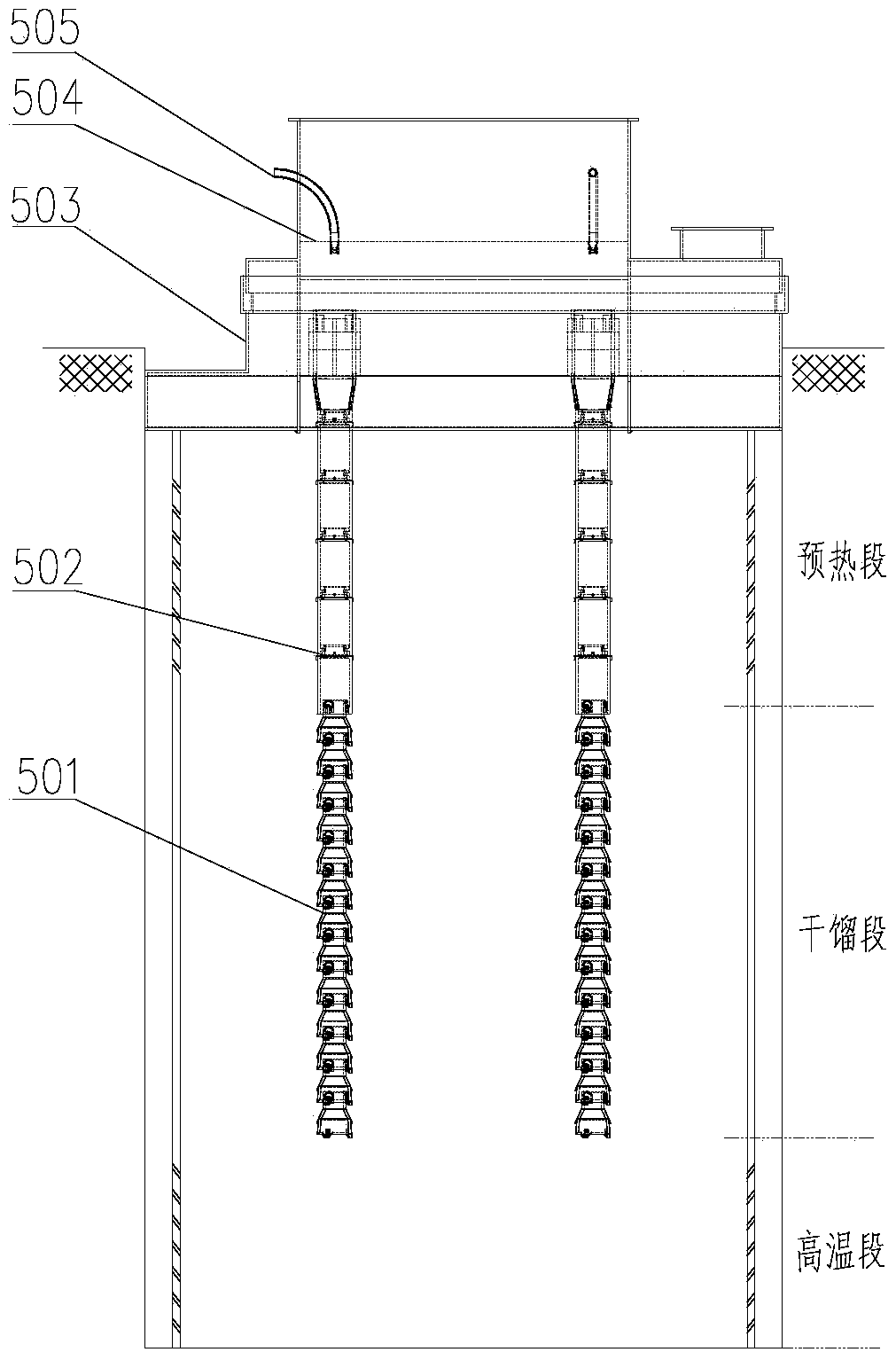

[0030] See figure 1 , is a structural schematic diagram of the device of the present invention, a low-order pulverized coal continuous carbonization process described in the present invention, the low-order pulverized coal raw material enters the externally heated continuous carbonization furnace 4 through a double-sealed feeding device 1 and a material buffer warehouse 2 , in the carbonization chamber, the raw coal gas in the furnace is collected by the gas collection device 5 extending from the furnace top into the middle of the retort section and the peripheral gas collection chamber 6, and is exported by the gas collection system 3; Discharge device; discharge device has 2 optional forms, discharge device one 7 is to discharge the cooled powder charge uniformly through coke discharge roller 702; discharge device two 8 is to discharge powdery, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com