Grounding/supporting device and plasma treatment equipment employing same

A support device and processing equipment technology, which is applied in the field of microelectronics, can solve the problems of carrier board level drop, uneven support and grounding, uneven charge distribution, etc., and achieve uniform support, uniform charge distribution, and good processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

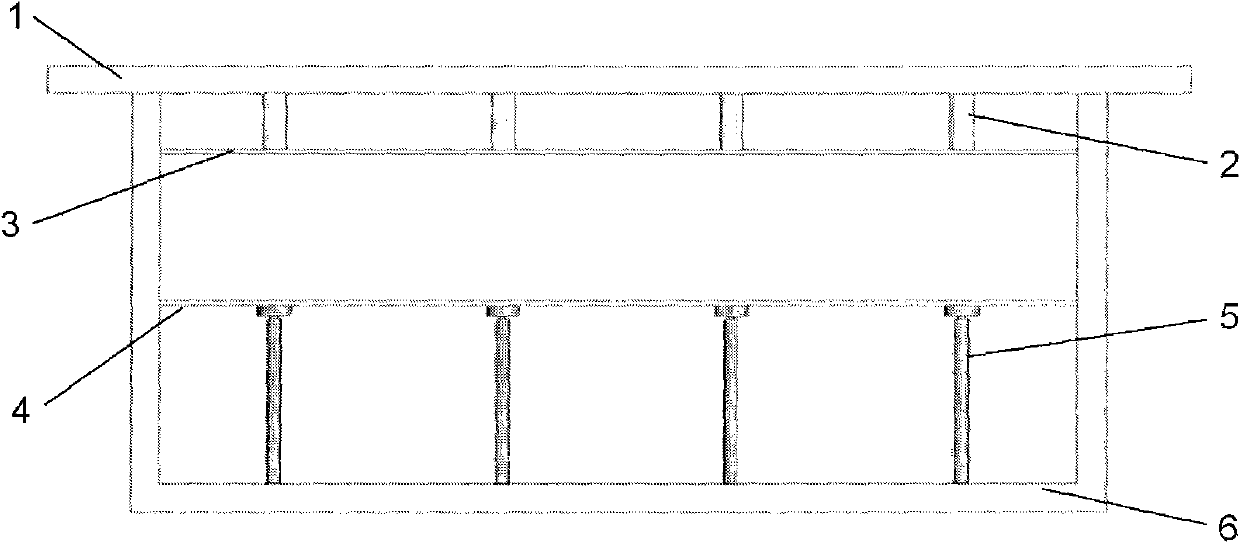

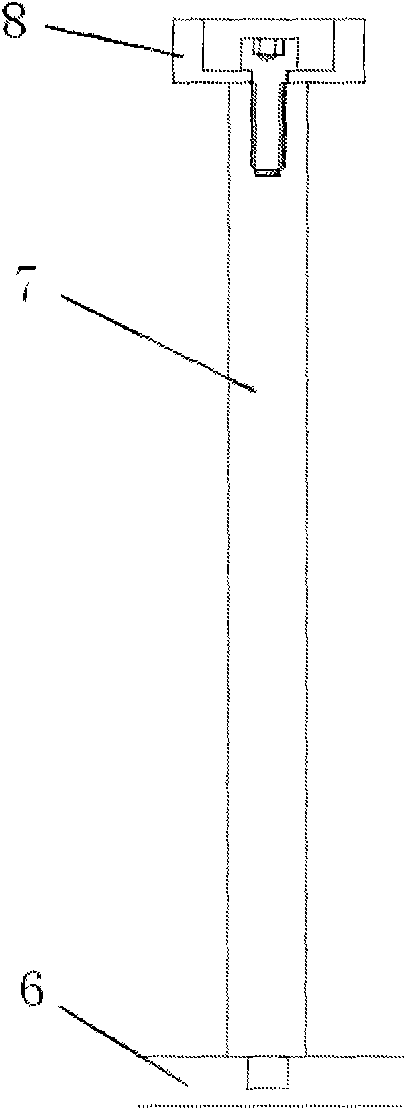

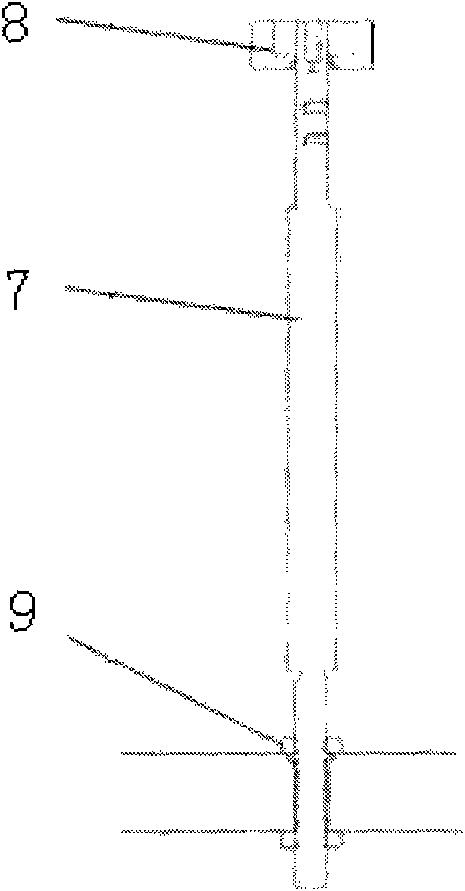

[0034] In order for those skilled in the art to better understand the technical solution of the present invention, the supporting device provided by the present invention and the plasma processing equipment using the supporting device will be described in detail below with reference to the accompanying drawings.

[0035]The support device provided by the present invention includes a rigid support column, a conductive carrier board contact part and an elastic component. Among them, the rigid support column is the main part of the support device; the carrier plate contact part is located at the top of the support column, and is used to support the carrier plate in the plasma processing equipment and make it electrically grounded; Variations occur in the elastic range and cause the overall height of the support means to vary. In practical applications, in order to ensure that the above-mentioned support device maintains good stability in high-temperature processes, the elastic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com