Coating adsorption device for BGA substrate

An adsorption device and coating technology, applied in the orientation of circuit board tools, electrical components, printed circuit manufacturing, etc., can solve the problems of BGA substrate breakage, uneven solder paste coating surface, affecting the quality of solder paste coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

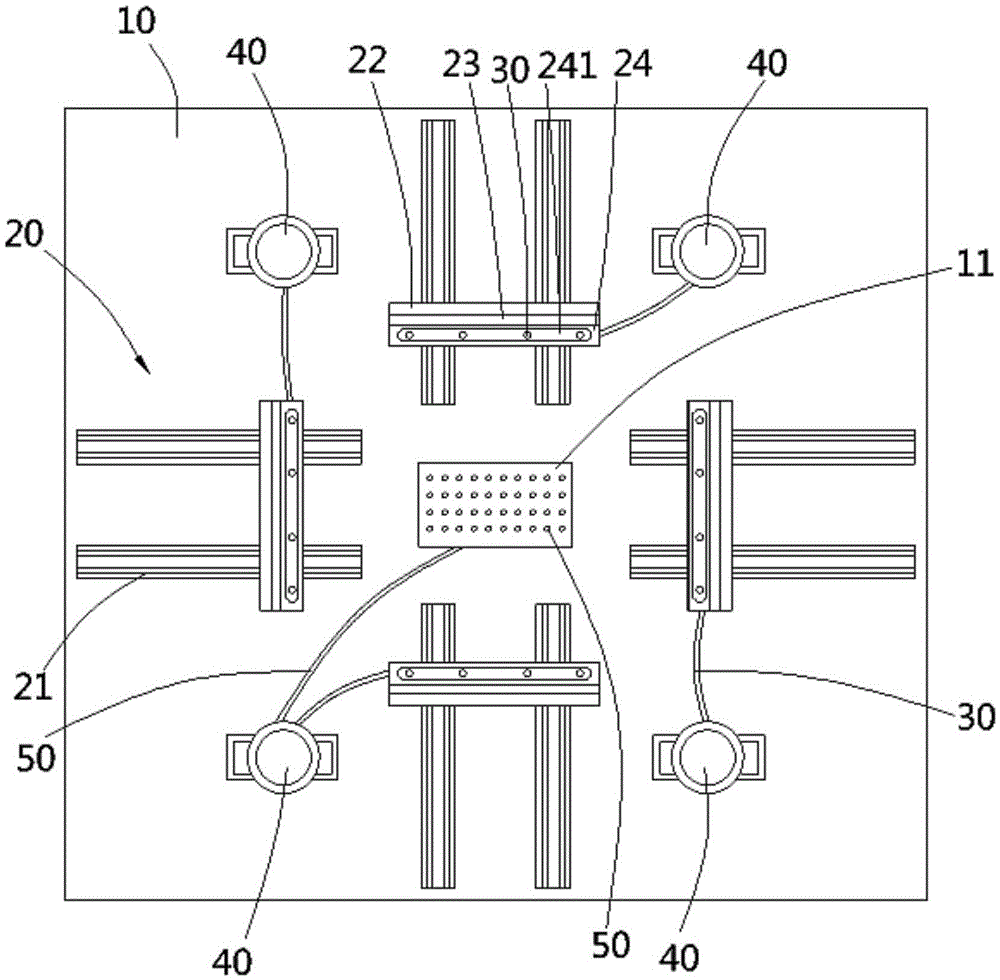

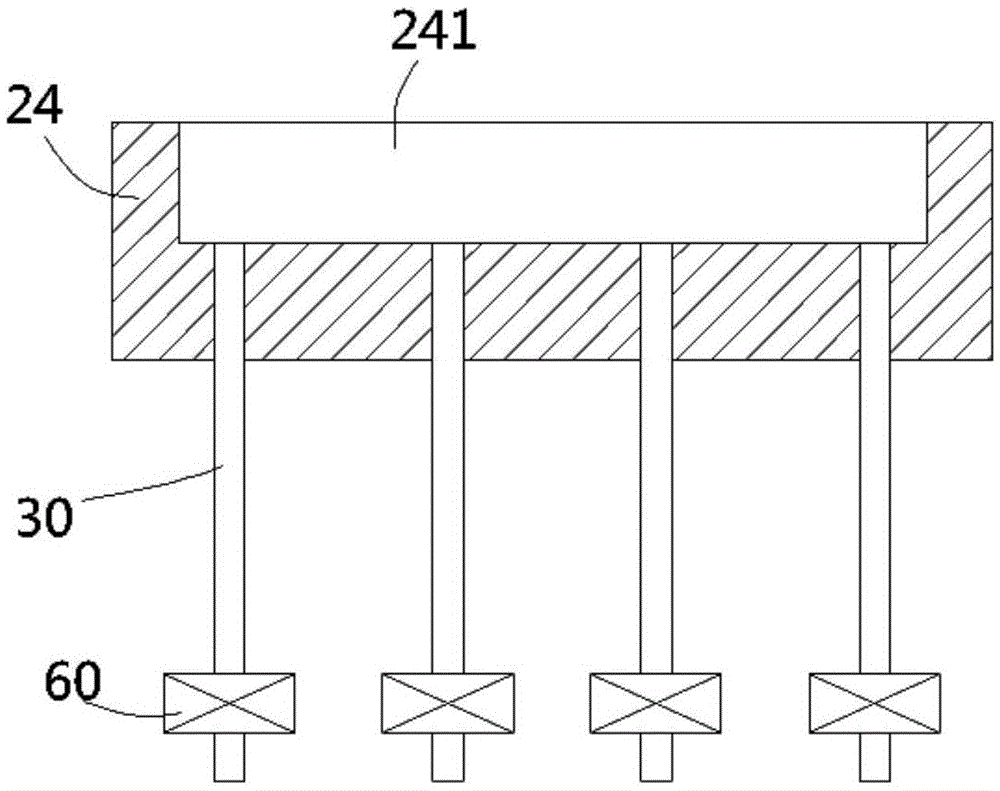

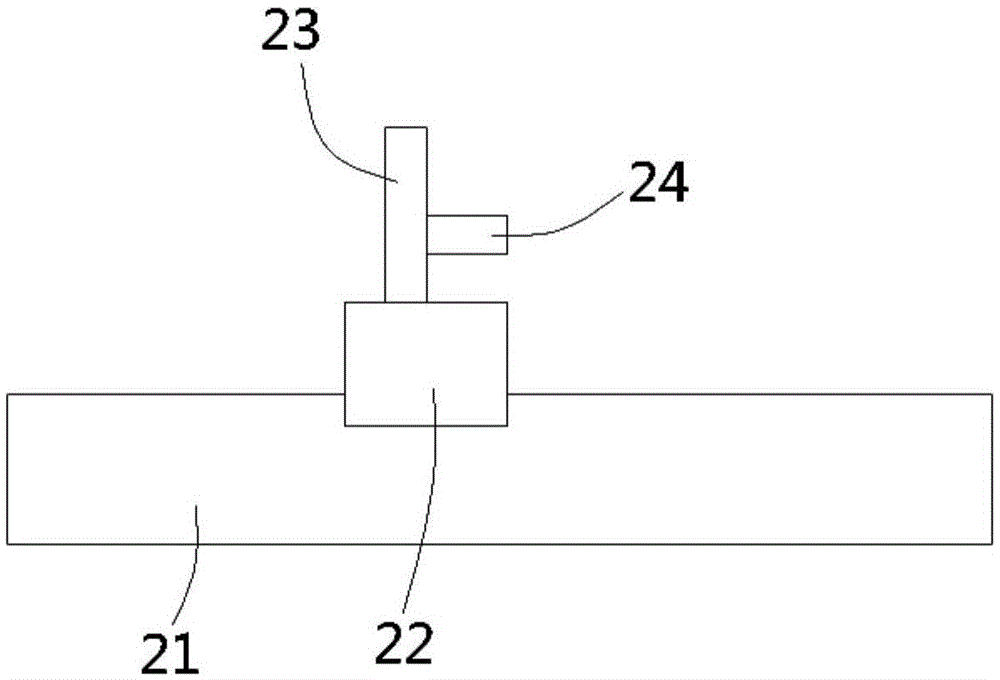

[0019] see Figure 1 to Figure 3 , a kind of coating adsorption device of BGA substrate according to the present invention, comprises base plate 10, and the cross-section of described base plate is rectangular or square, and base plate 10 is provided with four supporting adsorption mechanism 20, and described four supporting The adsorption mechanisms are respectively arranged on one side of the four sides of the upper end surface of the base plate 10, and the supporting adsorption mechanism 20 includes a linear guide rail 21 arranged on the upper end surface of the base plate 10, a carrier plate 22 slidably arranged on the linear guide rail, and a carrier plate fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com