Tight facial mask and preparation method thereof

A mask and manufacturing method technology, applied in the field of masks, can solve the problems of limited protection and improvement effect, low adhesion, flat non-woven masks cannot meet the requirements of high adhesion, etc., and achieve the effect of improving safety protection efficiency and improving rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

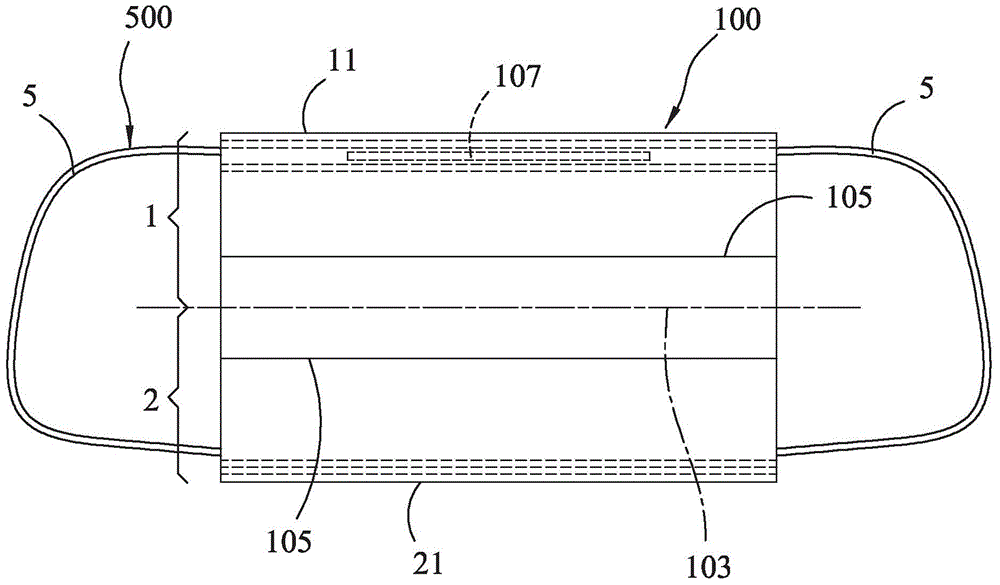

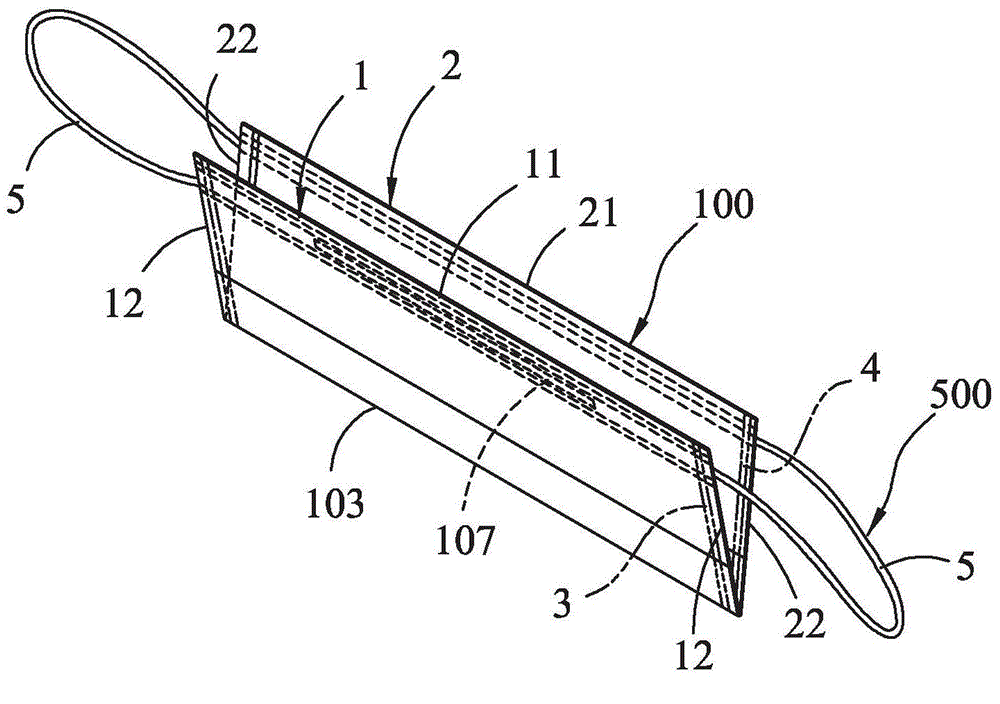

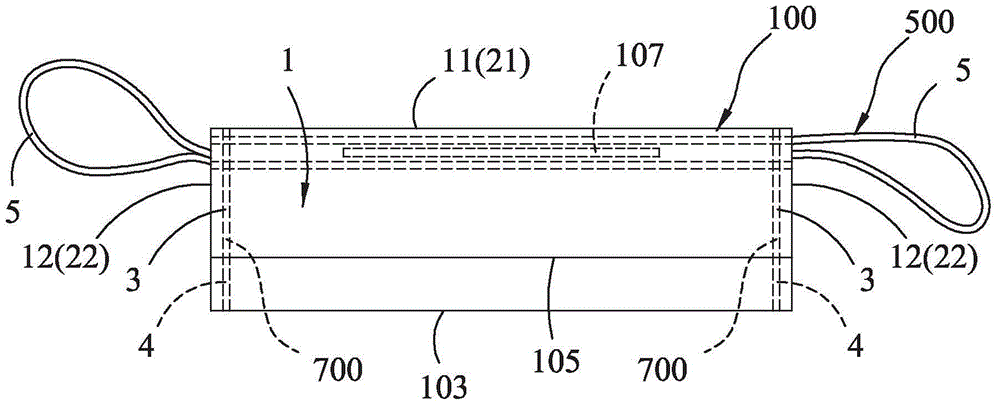

[0058] see figure 2 and image 3As the first embodiment of the present invention, the present invention provides a tight-fitting mask, which includes: a mask body 100 , a belt set 500 , a pair of upper joints 3 and a pair of lower joints 4 .

[0059] The mask body 100 includes an upper body part 1 and a lower body part 2, and the lower body part 2 is stacked or folded on the upper body part 1 to distinguish a sealing edge 103 between the upper body part 1 and the lower body part 2. The upper and lower body parts 1, 2 jointly have the outer sides 11, 21 set corresponding to the sealing side 103 and the two sides 12, 22 corresponding to each other, and the upper body part 1 is provided with a nose piece adjacent to the corresponding outer side 11 107. Wherein, at least two horizontal creases 105 are formed in the central region of the mask body 100, and the two horizontal creases 105 are respectively symmetrical to the sealing edge 103 (refer to figure 1 ), the mask body 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com