High-frequency high-voltage power supply with spark breakdown fast shutdown circuit

A high-frequency and high-voltage power supply and circuit shutdown technology, applied in power supply technology, electrostatic separation, etc., can solve the problems of inability to capture spark breakdown signals, reduce dust removal efficiency, equipment damage, etc., to improve system stability and improve dust removal efficiency. , the effect of avoiding power waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

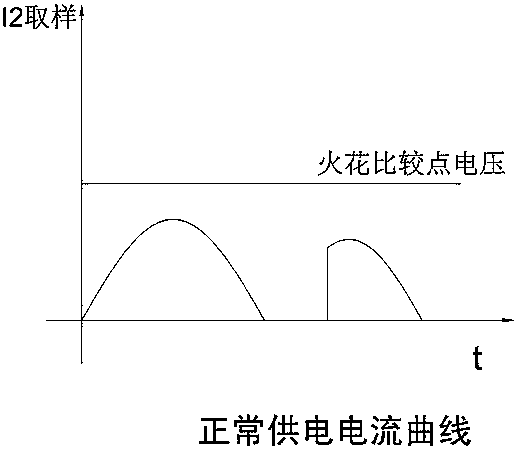

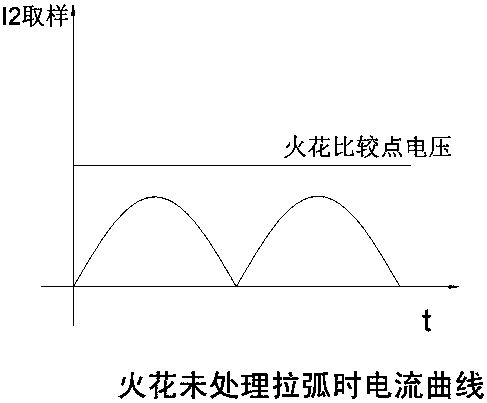

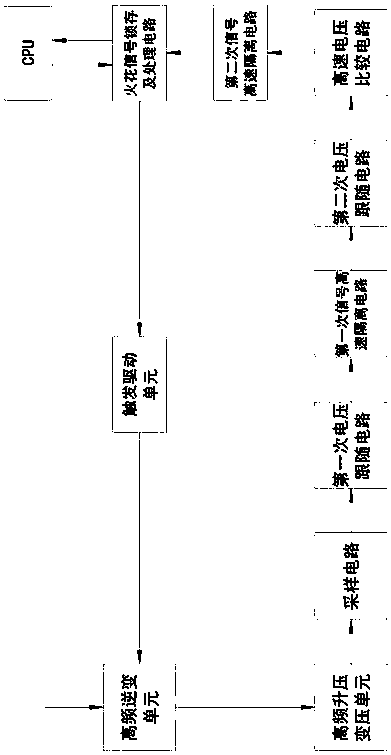

[0018] The specific embodiments of the present invention will be described below in conjunction with the drawings. Such as figure 1 Shown: a high-frequency high-voltage power supply with a spark breakdown fast shut-off circuit, as in the prior art, has a CPU, the CPU controls the trigger drive unit to drive the high-frequency inverter unit, the output of the high-frequency inverter unit and the high-frequency boost unit Different from the prior art, there is a sampling circuit connected to the output current of the high-frequency boost unit. The output of the sampling circuit passes through the first voltage follower circuit, the first signal high-speed isolation circuit, and the second voltage in turn. The follower circuit, the high-speed voltage comparison circuit, and the second signal high-speed isolation circuit are connected to the spark signal latch and processing circuit. The output of the spark signal latch and processing circuit is connected to the CPU and the other is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com