Pipe cleaner

A technology of pigs and components, applied in the field of pigs, to achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

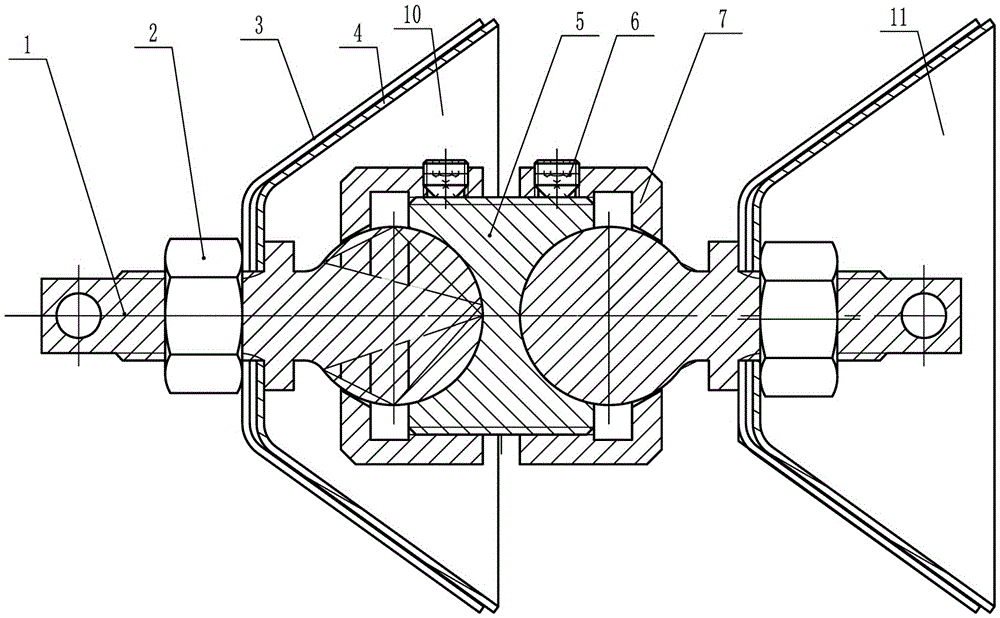

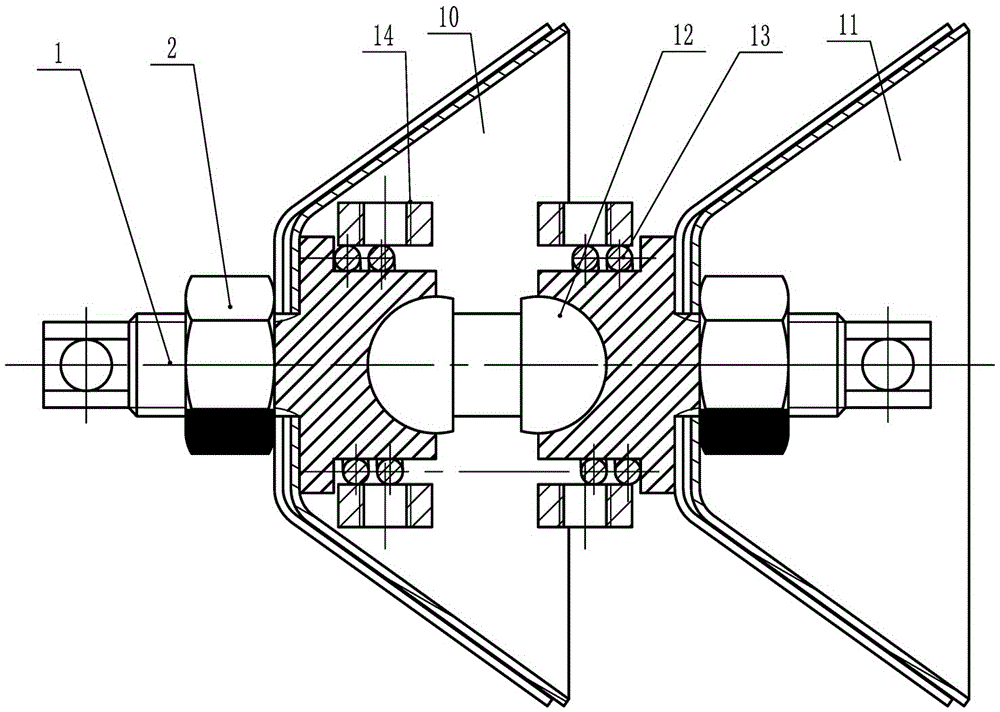

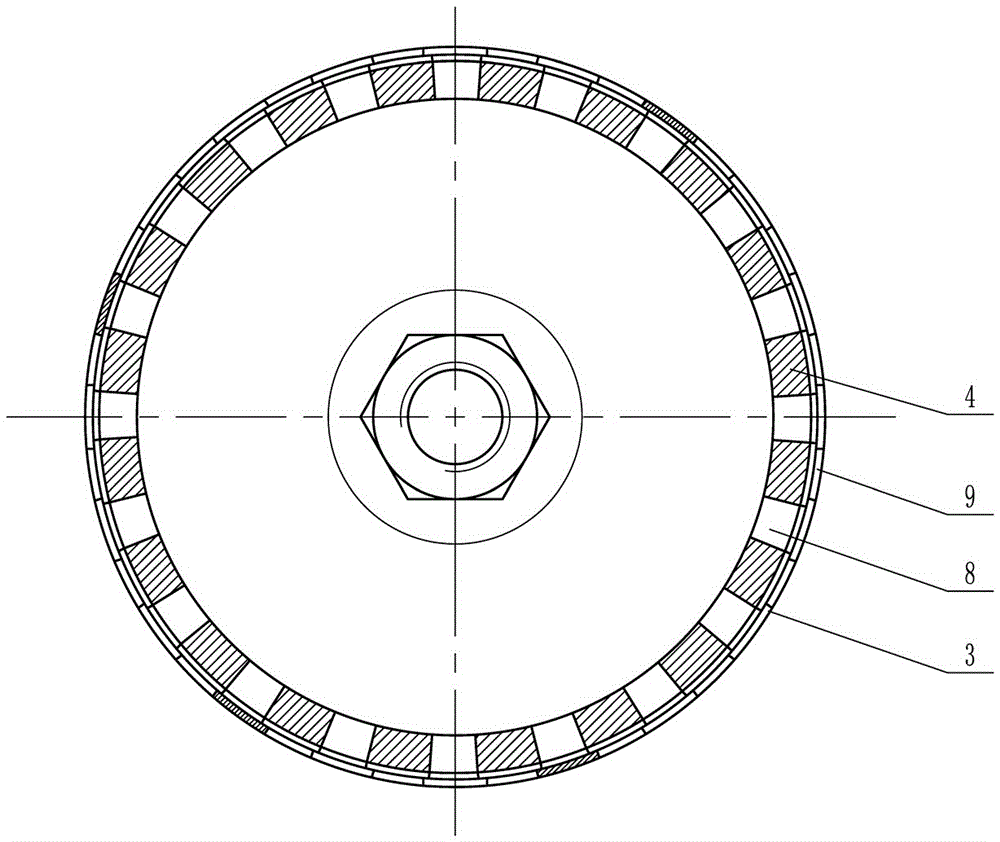

[0014] A pipe cleaner such as figure 1 , figure 2 , image 3 As shown, it includes a pig assembly composed of bowl-shaped inner and outer blades 4, 3 superimposed on the central shaft 1 through nuts 2, wherein the walls of the outer blade 3 and the inner blade 4 are evenly spaced in the radial direction. The slits on the inner and outer blade walls are alternately arranged, the width of the slit 9 on the outer blade wall is 4 mm, the width of the slit 8 on the inner blade wall is 4.5 mm, and the vertical distance between the inner and outer blades 4 and 3 is 3mm, the inner and outer blades 4 and 3 are made of 60Si2Mn spring steel sheets, and the thickness of the inner and outer blades is 1.5mm; the pig is connected in series by at least two groups of pig components 10 and 11 through a flexible connection structure. The two groups of pig assemblies 10, 11 are arranged in the same direction.

[0015] like figure 1 As shown, the bendable connection structure is that the ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com