A double bottom structure of an LNG carrier

A technology of liquefied natural gas and double bottom, applied in the direction of hull, hull, hull parts, etc., can solve the problems of increased fuel consumption, large increase of arch bending moment, unfavorable empty ship weight, etc., and achieve the effect of fuel consumption control and weight increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The embodiments are not intended to limit the scope of protection of the invention. Obviously, those skilled in the art can obtain other embodiments without having to pay creative work. Belong to the protection scope of the present invention.

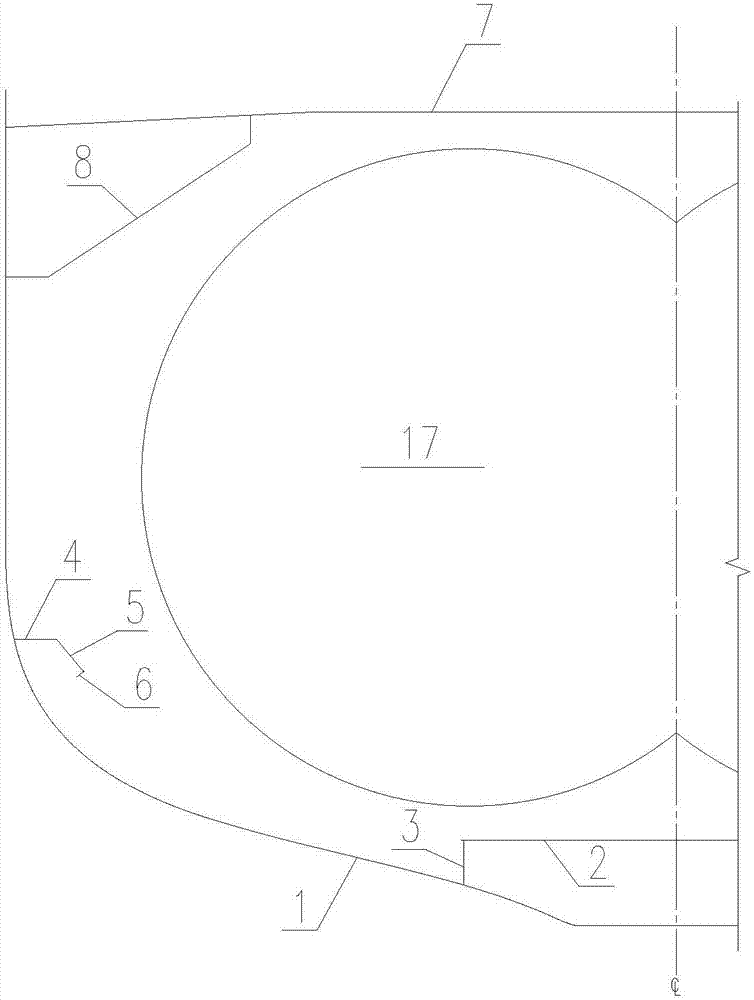

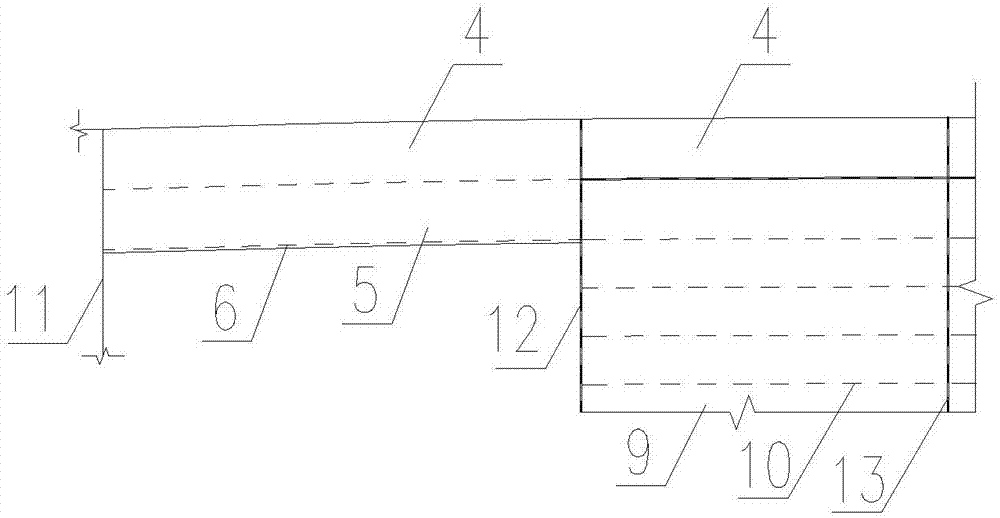

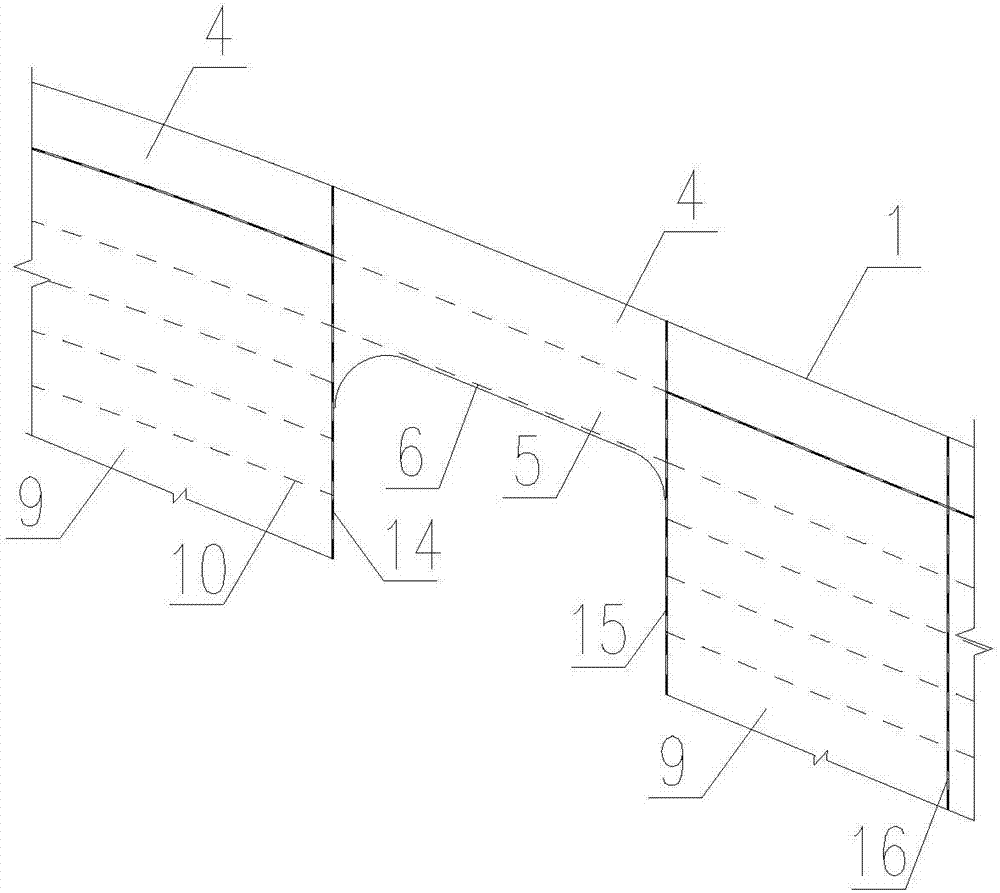

[0017] combine Figure 1 to Figure 3 As shown, a double bottom structure of a liquefied natural gas ship includes a hull shell 1, an inner bottom plate 2 and a C-type liquid cargo tank 17, the area of the stern near the front wall 11 of the engine room, and the middle of the area of the bow near the middle cargo tank, canceling the existing The watertight sloping plate of the side tank, the watertight bottom girder 3 is connected between the hull shell 1 and the inner bottom plate 2 to form a watertight perimeter, the watertight bottom girder, the hull shell and the inner bottom plate enclose a ballas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com