Aircraft cylinder heading installation structure

A technology for installing structures and gas cylinders, which is applied to aircraft parts, mechanical equipment, transportation and packaging, etc. It can solve the problems of general layout restrictions, difficulty in regular inspection and maintenance, and gas leakage, so as to improve maintainability and safety, and facilitate daily life Maintenance work, convenient disassembly and inspection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

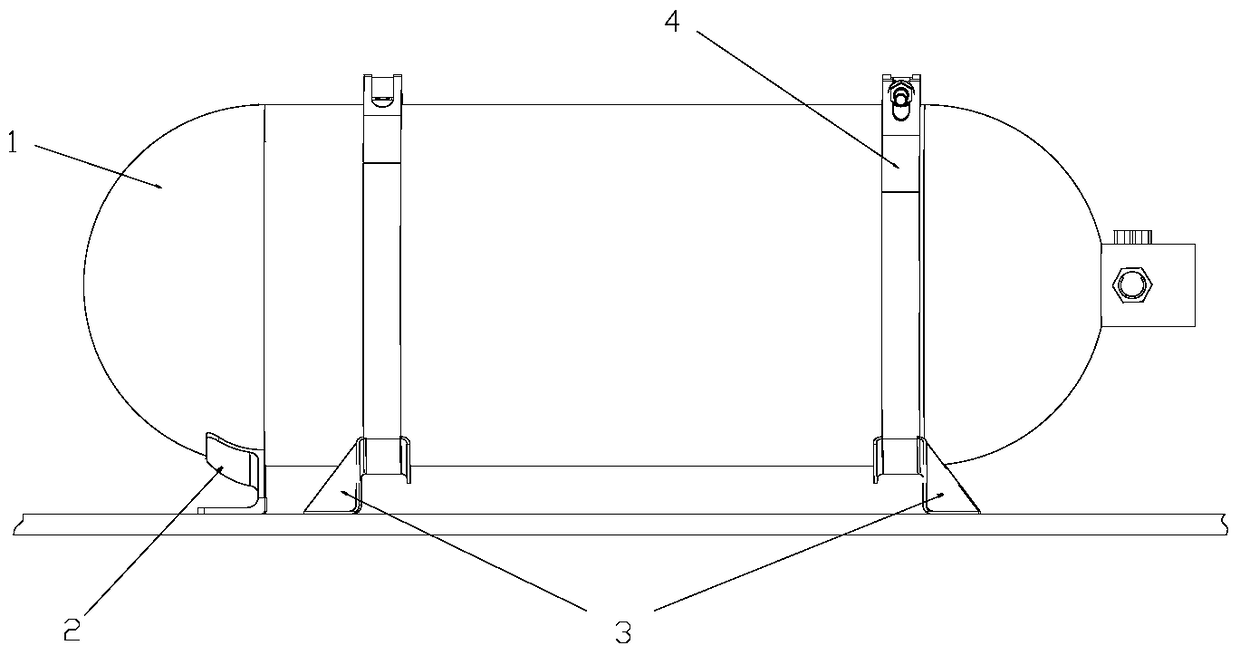

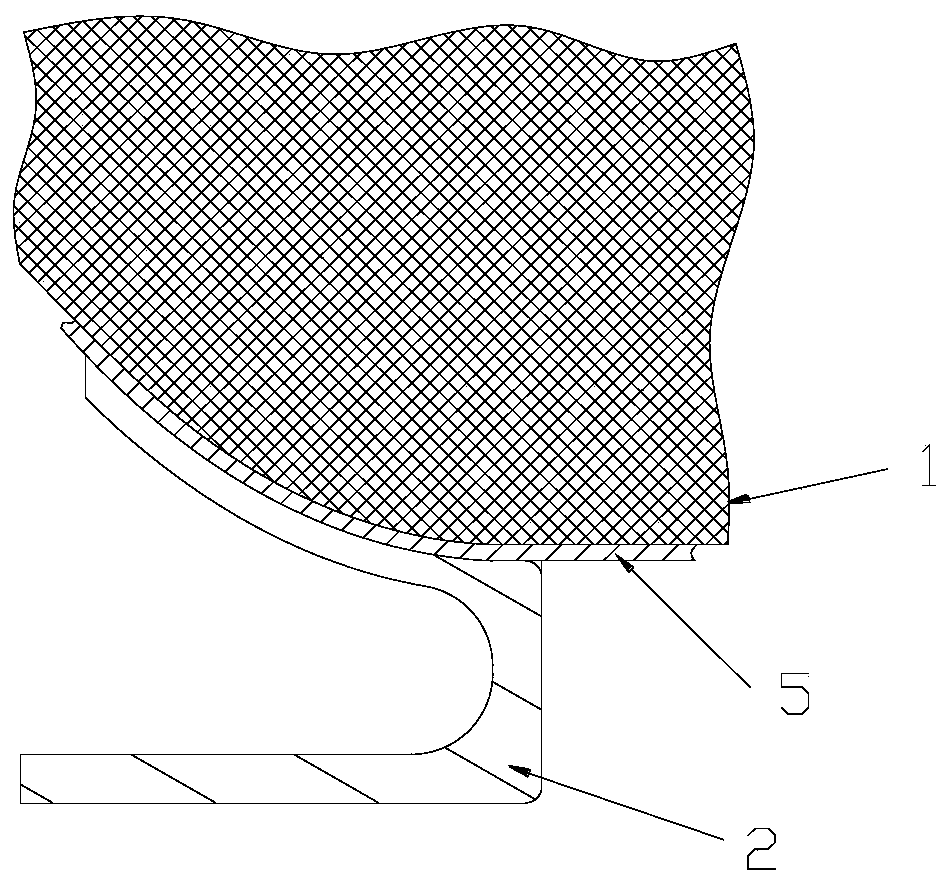

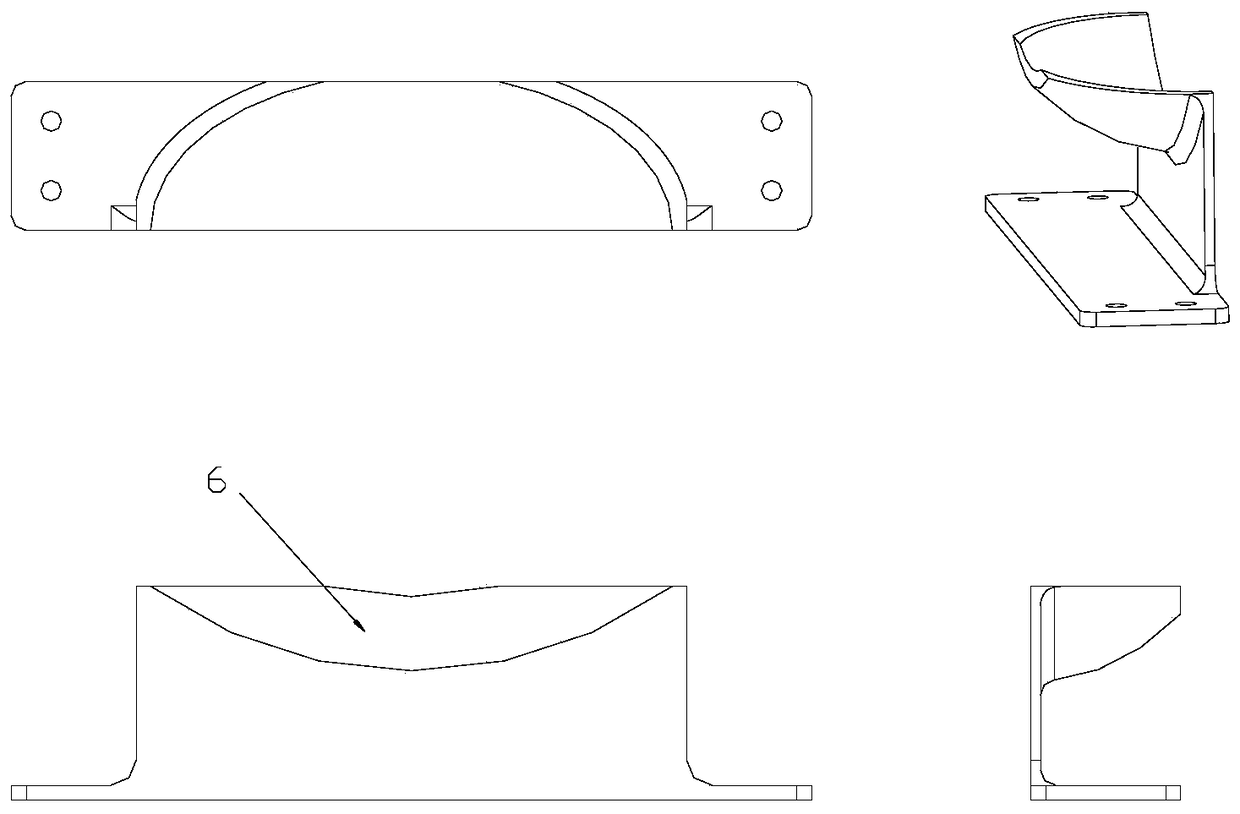

[0017] see Figure 1-Figure 4 , an aircraft gas cylinder heading installation structure, which is composed of a gas cylinder 1, a base 2, a bottom bracket 3, a clamp 4, and a buffer pad 5. The neck and bottom of the cylinder 1 are clamped by the clamp 4 to prevent their displacement. The gas cylinder 1 is limited by the base 2 to prevent its axial displacement under large overload, and the clamp 4 and the bottom bracket 3 are connected together by riveting; Use HB7792-2005J glue or other adhesive with similar performance to stick the buffer pad 5 on the clamp 4, and allow thickening of the buffer pad 5 during installation to ensure that the gas cylinder 1 is closely attached; use XY401 / HB7792-2005J glue or performance The buffer pad 5 is bonded to the base 2 by other adhesives that are close to it, and the buffer pad 5 is allowed to be thickened to ensure that the gas cylinder 1 is in close contact with it during installation.

[0018] There is a buffer pad 5 between the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com