A piezoelectric sounding structure and mobile terminal

A sounding structure and mobile terminal technology, applied in the field of speakers, can solve the problems of weak sounding, short circuit of piezoelectric ceramic speakers, unreliable welding, etc., and achieve the effects of good piezoelectric deformation conduction, improved sounding effect, and simple and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

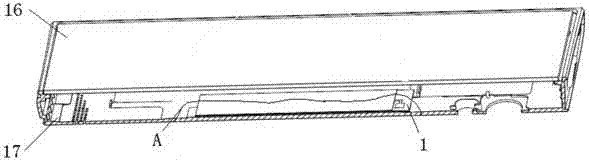

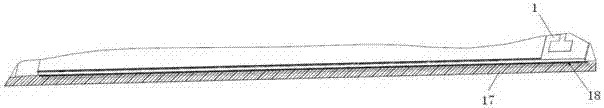

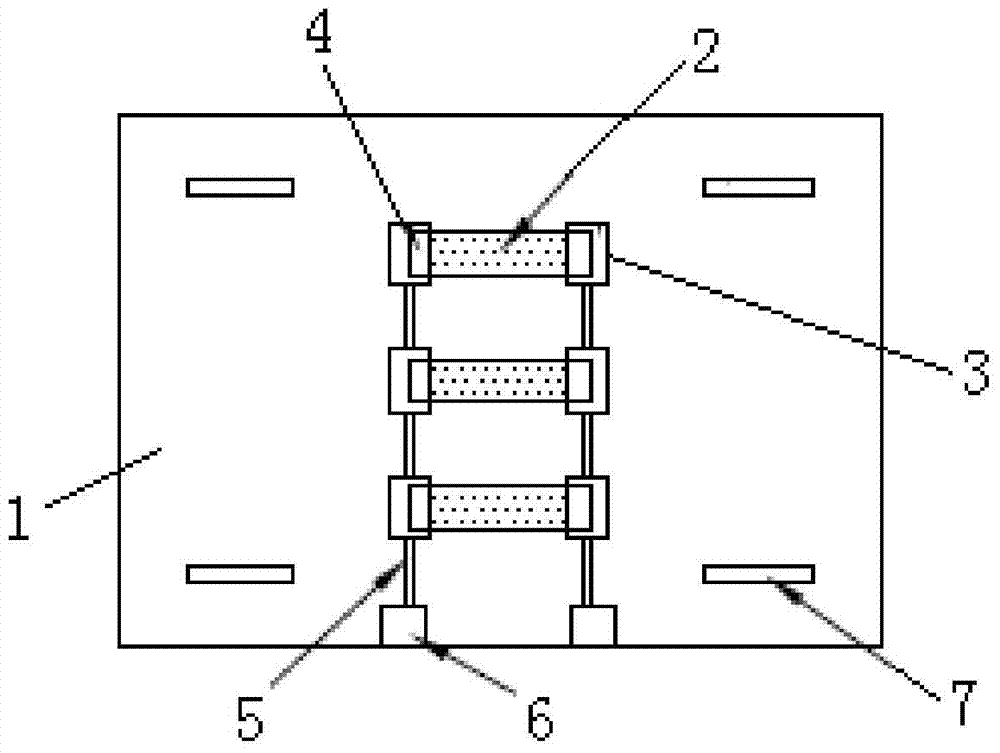

[0042] This embodiment provides a piezoelectric sound generating structure, such as figure 1 with figure 2 As shown, the piezoelectric sound generating structure includes a PCB board 1 and three piezoelectric ceramics 2 tightly coupled to the front surface of the PCB board 1. The PCB board 1 is provided with copper foil pads 3, solder joints 4, signal copper foil wires 5 and signal input pads 6 corresponding to three piezoelectric ceramics 2 respectively. The signal copper foil wire 5 inputs the signal to the pads 6 and the copper foil pad 3 are connected in sequence. The PCB board 1 is also provided with tuning holes / slots 7 for adjusting the vibration mode. The tuning holes / slots 7 can be single or multiple. The tuning holes / slots 7 can be round, square, or oval. 形等。 Shape and so on. By changing the number, shape, and arrangement of the tuning holes / slots 7, the mechanical deformation mode of the PCB board 1 can be adjusted, thereby optimizing the acoustic curve and optimizi...

Embodiment 2

[0048] This embodiment provides a piezoelectric sound generating structure, such as Figure 5 As shown, it adopts a double-sided mounting process on the basis of Embodiment 1. The upper and lower sides of the PCB board 1 are respectively provided with pads, which are a surface pad 8 and a bottom pad 9, respectively. The surface pad 8 and the bottom pad 9 are respectively provided with a surface layer piezoelectric ceramic sheet 10 and a bottom layer piezoelectric ceramic sheet 11 respectively. The ceramic end electrodes of the piezoelectric ceramic sheets on both sides are closely connected with the pads on both sides of the PCB board through a welding process.

[0049] Since the piezoelectric sound generating structure of this embodiment is provided with piezoelectric ceramics on both sides of the PCB board, it can effectively enhance the mechanical vibration driving effect and greatly improve the sound pressure output.

[0050] Among them, the piezoelectric ceramic in this embodi...

Embodiment 3

[0052] This embodiment provides a piezoelectric sound generating structure, such as Image 6 As shown, the structure is basically the same as that of the first embodiment, including a PCB board 1 and a piezoelectric ceramic 2 tightly coupled to the PCB board 1. The difference is that in this embodiment, the piezoelectric drive chip 12 (such as TI's TPA2100P1) is directly integrated on the PCB board 1, so that the piezoelectric drive circuit 13 can be shortened and the EMI noise of the circuit can be reduced; while the piezoelectric element Unlike traditional moving coil speakers, it does not contain electromagnetic components and basically does not produce EMI noise. At the same time, for different piezoelectric elements, the drive circuit can be directly configured to the optimal drive parameters (impedance characteristic matching, frequency characteristic correction), truly realizing the plug and play function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com