Rice hull steaming machine

A technology of rice husks and shells, which is applied in the preparation of alcoholic beverages, etc., and can solve the problems of uneven quality of rice husks, low output, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

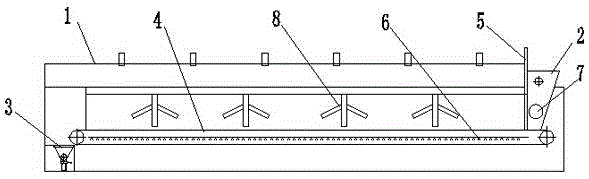

[0015] The present invention comprises a shell 1, a feed port 2 arranged at one end of the shell 1, and a discharge port 3 provided at the other end of the shell 1; a rotating chain plate 4 is arranged between the feed port 2 and the discharge port 3 , between the feeding port 2 and the rotating chain plate 4, a gate plate 5 for controlling the feeding height is established, and a steam pipeline 6 is established below the rotating chain plate 4; The material is evenly arranged in the transverse direction.

[0016] The casing 1 is sealed to form a seal for materials.

[0017] The casing 1 is evenly distributed with a number of stirring paddles 8 along the axial direction, and the stirring paddles 8 extend into the rice husk to form the upside down turning of the rice husk.

[0018] Described stirring paddle 8 is hinged on the housing 1, and it can rotate and make it leave rice husk when not stirring.

[0019] The working process of the present invention is as follows: the ric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com