Gravel pack sand prevention pipe column installed when wellhole is flushed, for horizontal well

A technology of gravel packing and sand control pipes, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems of increased sand production, long well-occupancy period, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

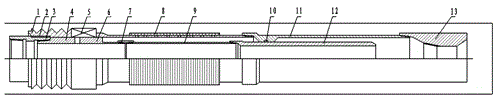

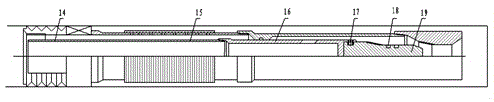

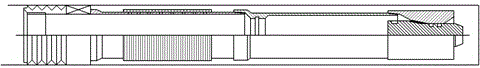

[0021] Such as figure 1 As shown in the figure, the gravel-packed sand control pipe string is lowered while flushing in the horizontal well, and the sand control integrated pipe string for the horizontal well is composed of the outer pipe string 1 for flushing and prevention, the inner pipe string 4 for sand washing and the inner pipe string 14 for extrusion packing sand control.

[0022] Outer tubing string 1 is composed of suspended packer 2, sand control screen 8, bottom filling outer tool 11 and sandblasting pipe 13 which are sequentially threaded, and suspended packer 2 is composed of lost packer The hand mechanism 3 and the suspension packing device 5 are composed, the bottom filling outer tool 11 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com