Worm wheel-worm hoop and rubber pipe assembly and installation method thereof

A worm gear and rubber hose assembly technology, which is applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as roundness deformation of rubber hoses, stoppage of automobile assembly lines, and affecting product performance. To achieve the effect of firm fixation and avoid roundness deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

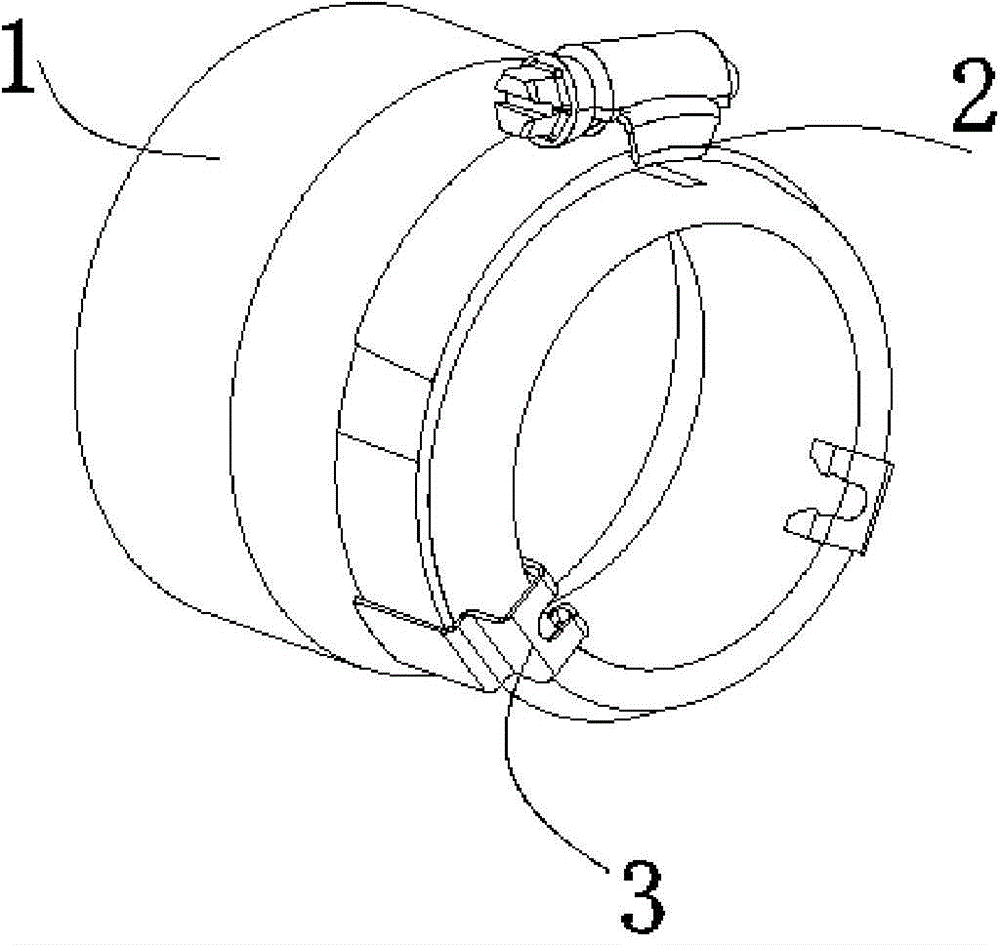

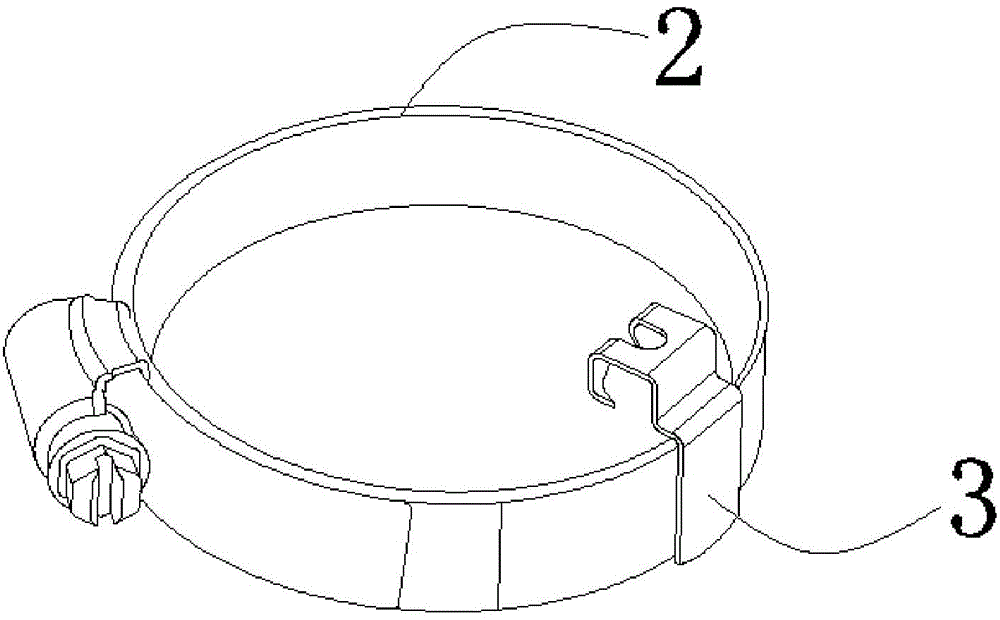

[0023] Device embodiment

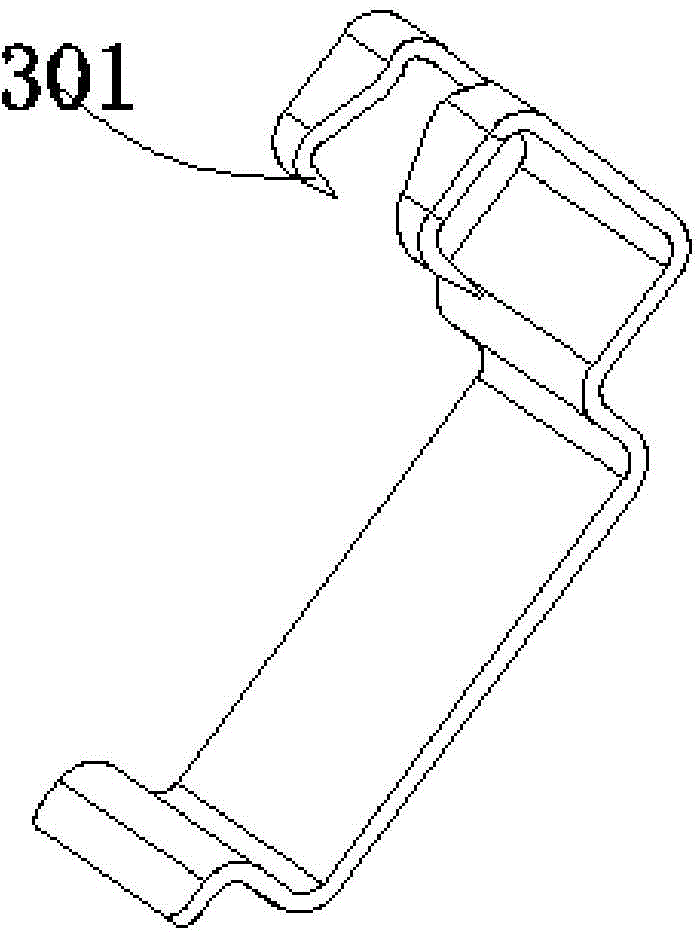

[0024] The present invention provides a worm gear clamp rubber hose assembly, including a rubber hose 1 and a worm gear clamp 2, the worm gear clamp 2 is installed at the port of the rubber hose 1, and The steel belt of the ring is provided with a bow-shaped claw 3, and the width of the bow-shaped claw 3 is 8-10mm and the thickness is 0.5-0.7mm, such as figure 1 with figure 2 shown. The upper end of the bow-shaped claw 3 is an inwardly bent pointed claw head 301 , and the pointed claw head 301 is used to engage with the edge of the port of the rubber hose 1 . At least 2 of the pointed claw heads 301 are arranged side by side on the width of the bow-shaped claw 3, and the pointed claw heads 301 are sheet-like structures, and the material is a metal material, such as i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com