Gear dynamic stress test device

A testing equipment, dynamic stress technology, applied in the testing of machine gear/transmission mechanism, testing of mechanical components, force/torque/work measuring instrument, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

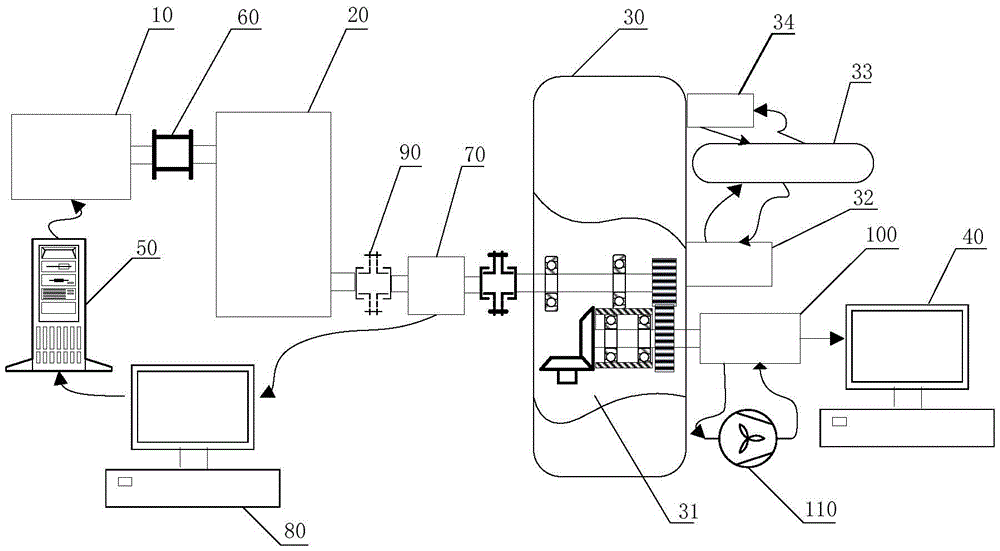

[0034] refer to figure 1 , the preferred embodiment of the present invention provides a kind of gear dynamic stress testing equipment, comprises motor 10, is used as the power source of dragging; Pass to accessory transmission system 30 after; Accessory transmission system 30, comprise the gear to be tested 31 and the engine accessory 34 and / or aircraft accessory 32 that are loaded on the gear to be tested 31, be used for undertaking the rotating speed that speed increaser 20 transmits, drive The gear to be measured 31 rotates; the strain gauge is arranged on the web plate of the gear to be measured 31, and is used to collect the strain signal of the gear to be measured 31; Measure the strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com