High-speed lubricating grease tester and testing method thereof

A testing machine and grease technology, which is applied in the direction of mechanical devices, measuring devices, instruments, etc., can solve the problems that the high-speed grease lubrication performance cannot be fully inspected, the test requirements cannot be met, and the test bearing speed is low. Achieve the effect of reducing test cost, saving time, and convenient disassembly

Inactive Publication Date: 2016-01-13

ANYANG INST OF TECH

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, general high-speed grease testing machines are driven by external power sources, and more than four sets of bearings are used for testing, including two sets of companion bearings and two sets of test bearings. Each test needs to replace four sets of bearings, and the test cost is relatively high. High, and the disa

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

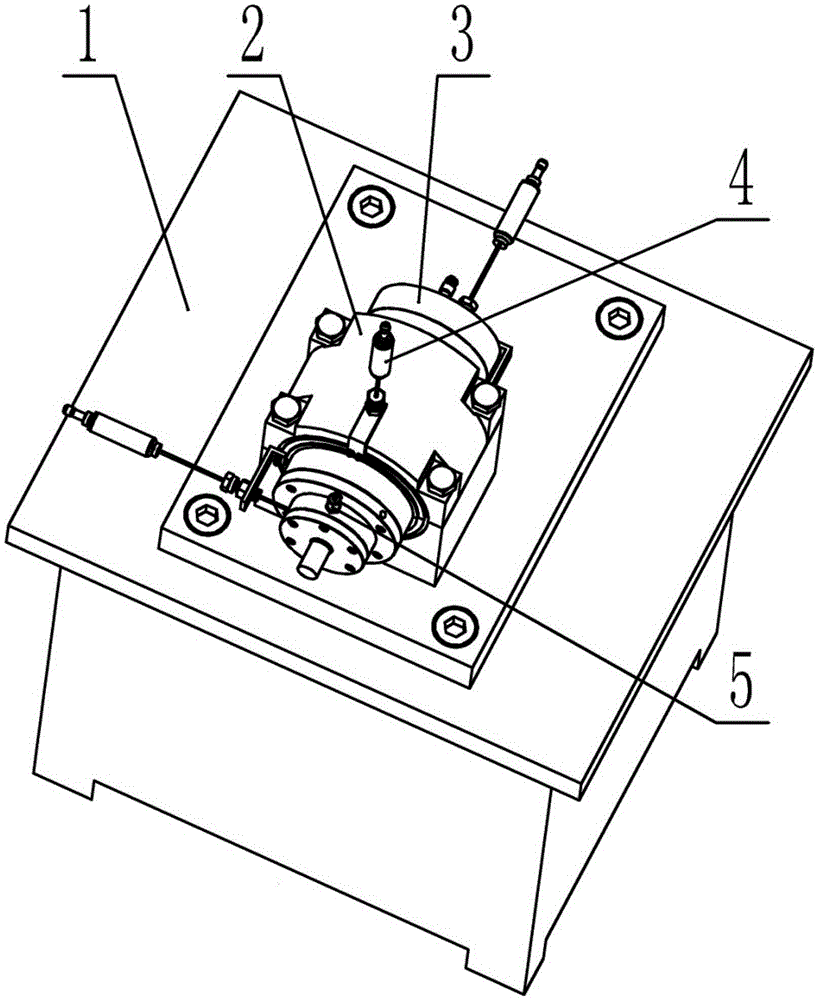

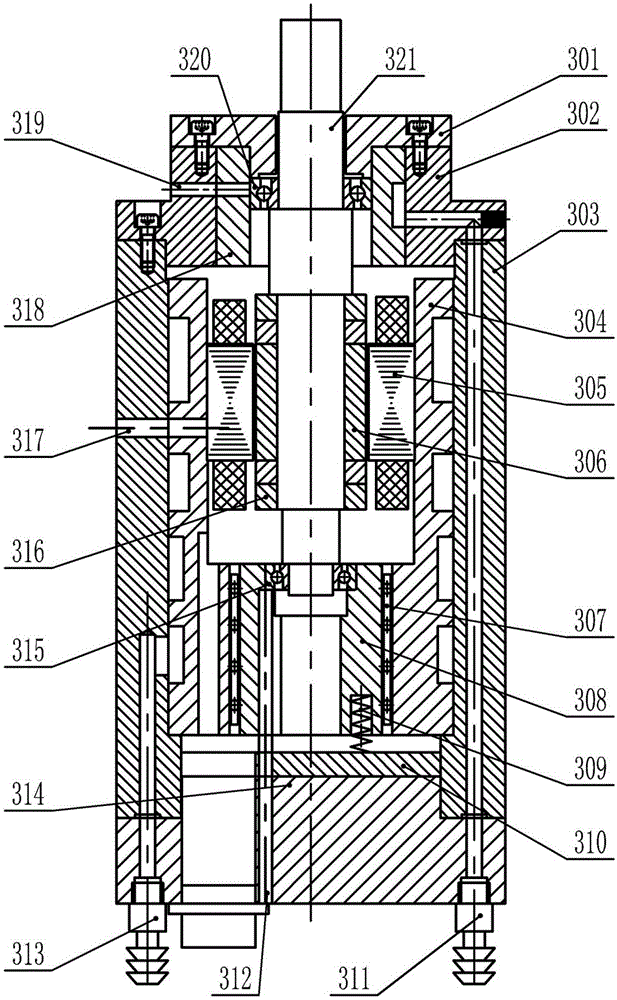

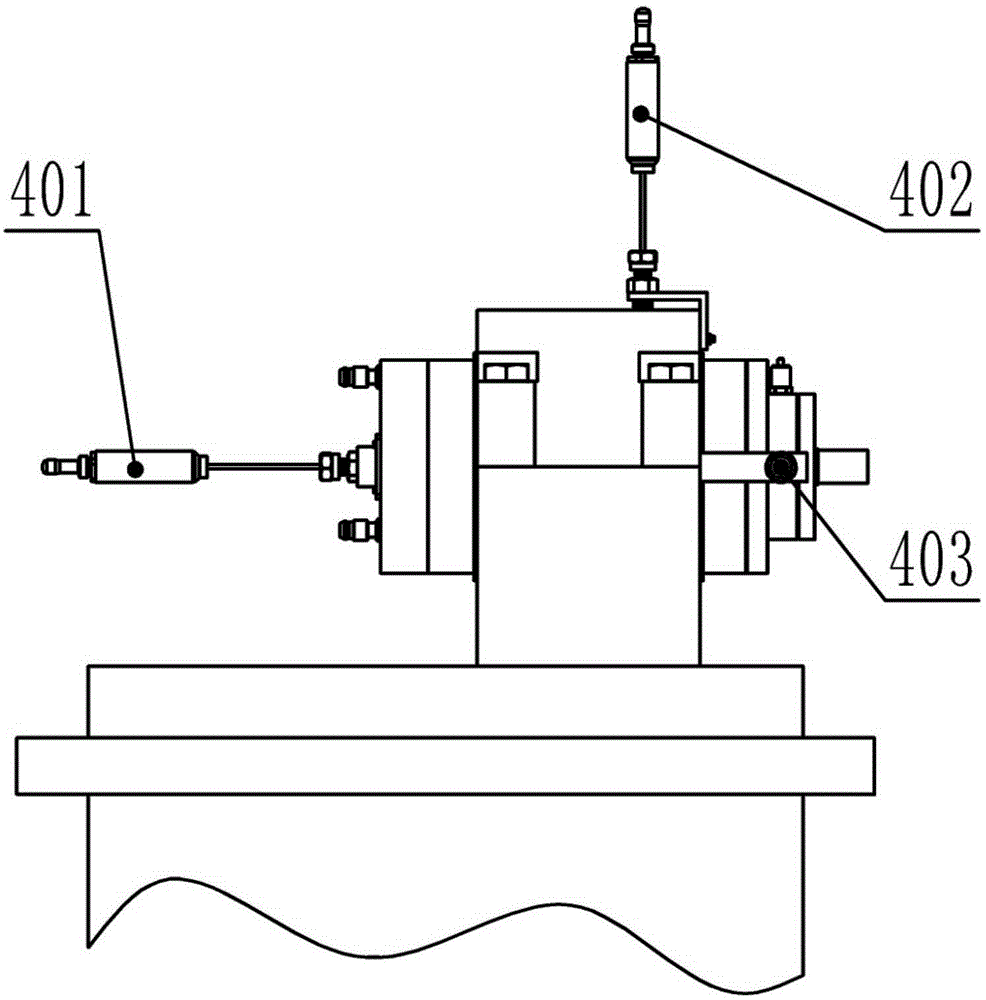

In the prior art, the traditional high-speed lubricating grease tester has disadvantages of low rotation speed, trouble disassembly and assembly, high testing cost, being lack of researches on the testing method and the specification, and the like. A purpose of the present invention is to overcome the disadvantages of the traditional high-speed lubricating grease tester in the prior art. The present invention provides a high-speed lubricating grease tester and a testing method thereof. The program comprises that the high-speed lubricating grease tester comprises a cooling system, a frequency conversion controller, a computer testing system and a base, wherein a tester is fixed on the base through a clamper and is the electric main shaft, the electric main shaft is connected to a computer control system through the frequency conversion controller, the electric main shaft is cooled through the cooling system, the front bearing of the electric main shaft is the testing bearing, the rear bearing of the electric main shaft is the accompany testing bearing, the outer ring of the accompany testing bearing is connected to a first temperature sensor, the stator outer side wall of the electric main shaft is connected to a second temperature sensor, the outer ring of the testing bearing is connected to a third temperature sensor, and a vibration sensor is fixed on the bearing seat of the testing bearing through a blind hole.

Description

technical field [0001] The invention relates to the technical field of bearing lubrication and grease testing, in particular to a testing machine and a testing method for high-speed grease. Background technique [0002] With the development of science and technology, the application fields of electric spindles are all over the machine tool industry, electronic processing industry, mold processing industry and all industries that require high-speed rotation and high efficiency. New requirements have been put forward, because grease lubrication does not require any auxiliary equipment, and is environmentally friendly and pollution-free, it has attracted more and more attention. The high-speed grease testing machine provides reliable data reference for the performance index of grease through the rotation test of grease-lubricated bearings. [0003] At present, general high-speed grease testing machines are driven by external power sources, and more than four sets of bearings a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N19/00

Inventor 何强李安玲李丽丽沈远黄文明李均韩加强岳秀运杨光

Owner ANYANG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com