A method for judging the use end point of film-forming liquid

A technology of film-forming liquid and end point, which is applied in the field of preparation of brittle capsules for cigarettes, can solve problems such as increased defective product rate, substandard mechanical strength, waste of film-forming liquid, etc., and achieves low cost, fast and accurate viscosity detection, achieve convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

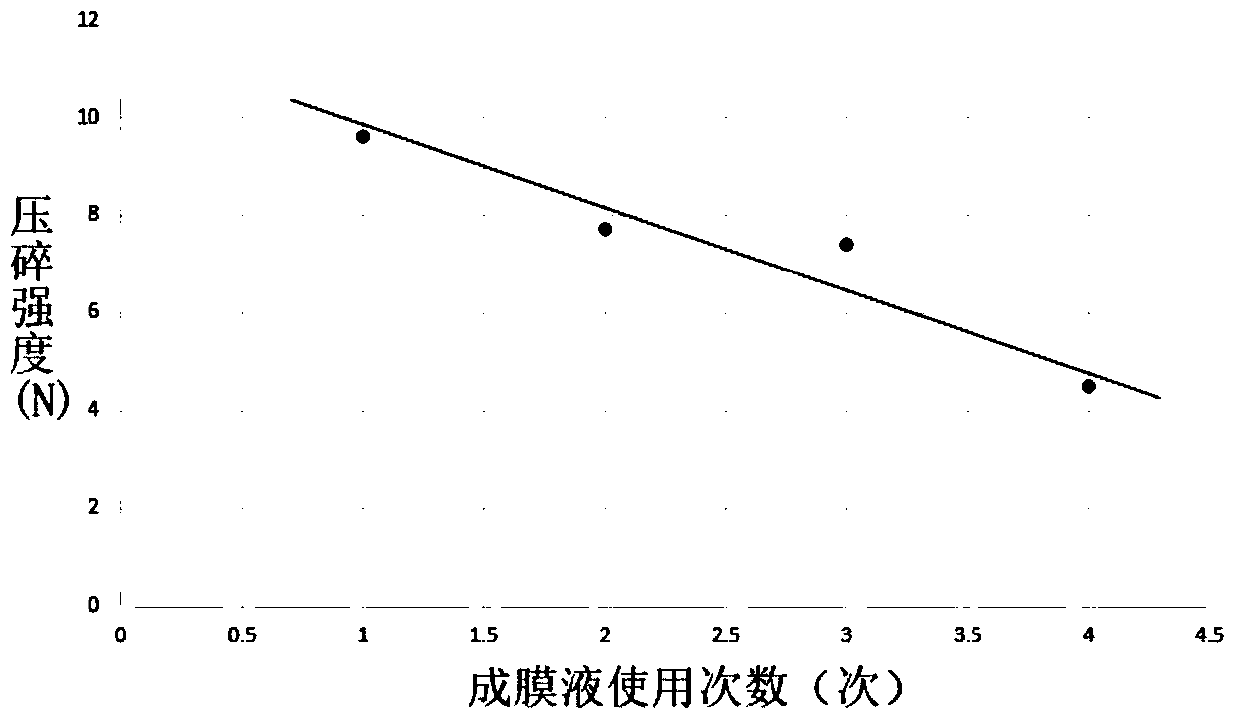

Problems solved by technology

Method used

Image

Examples

Embodiment 1

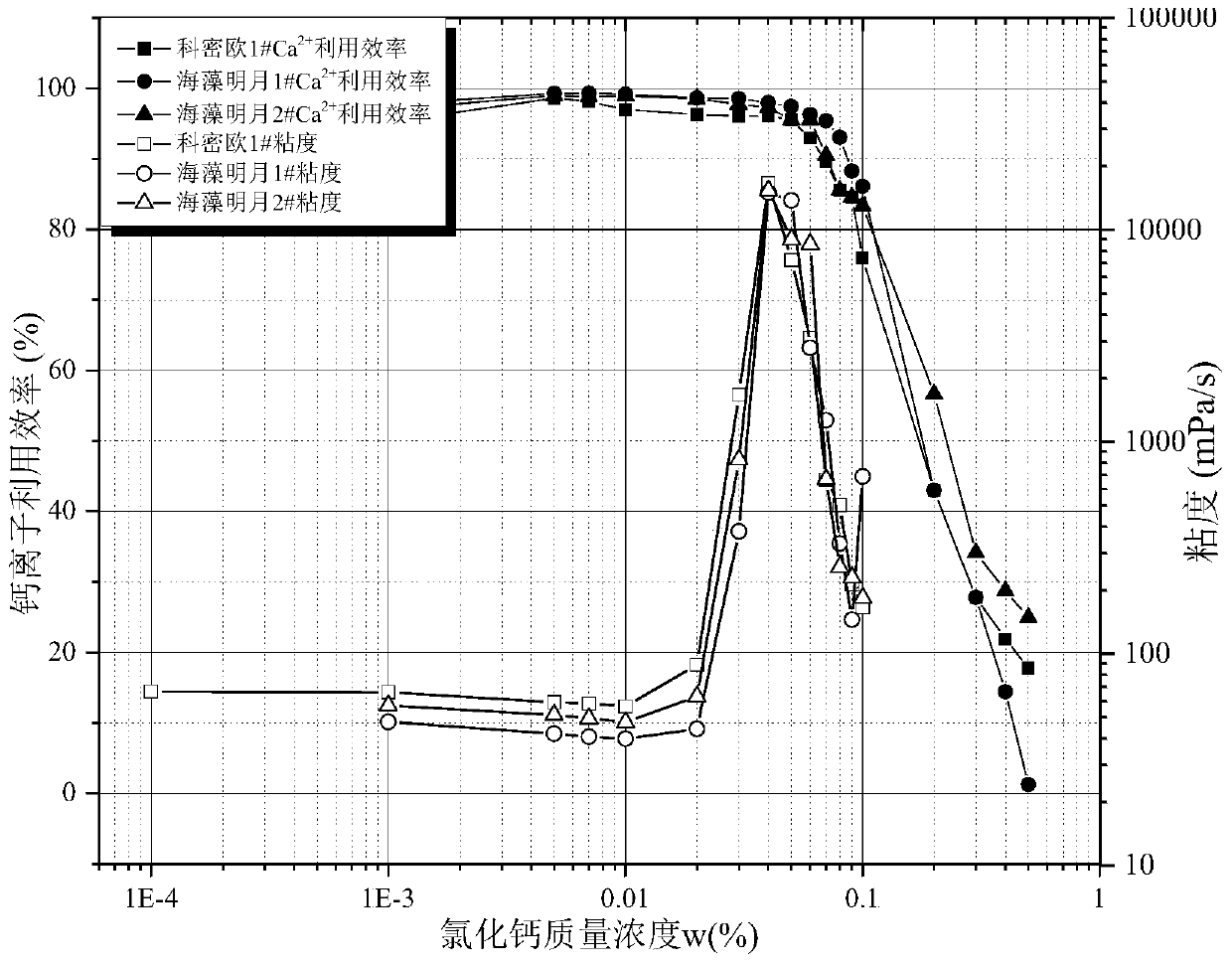

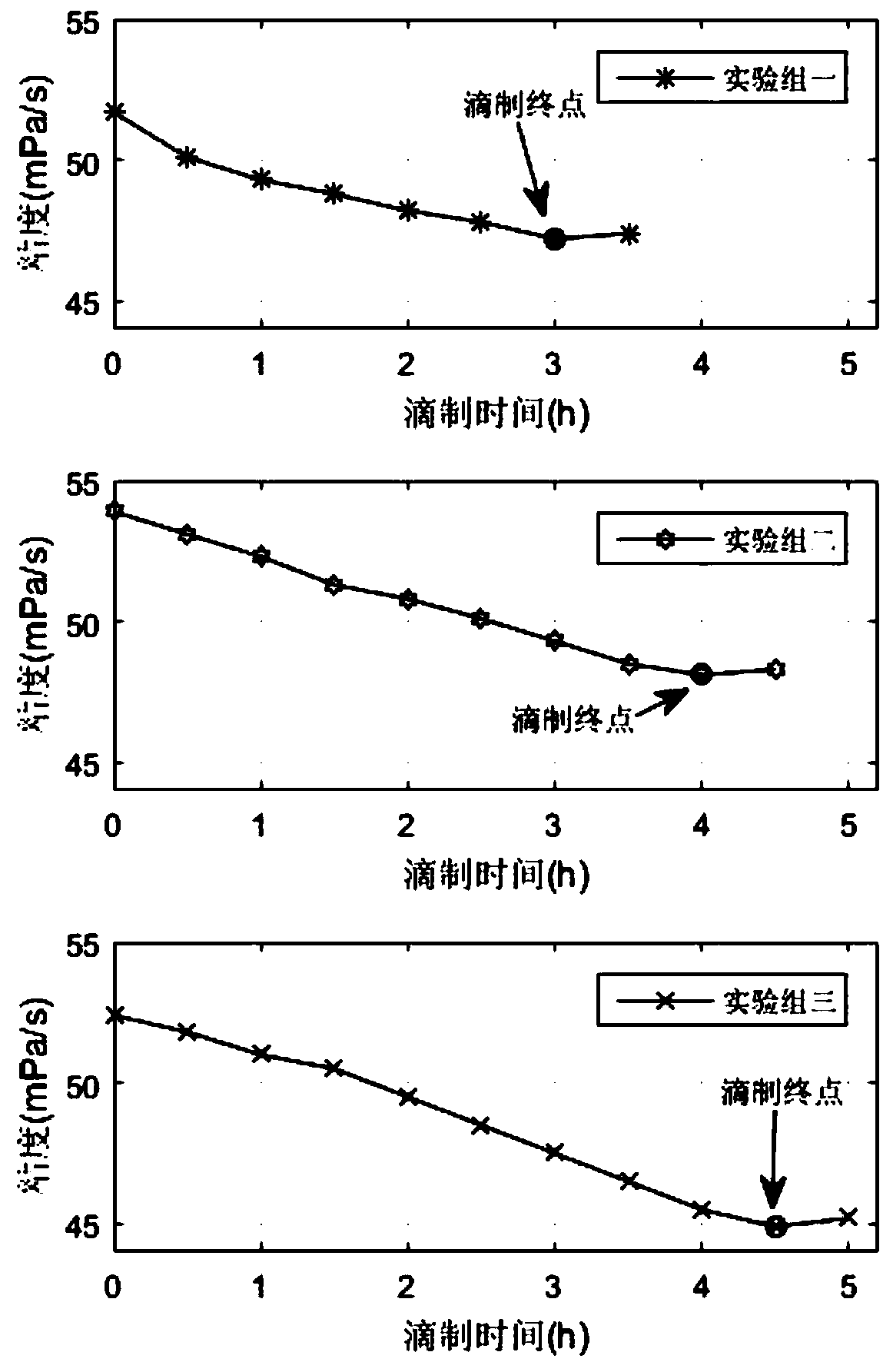

[0029] A method for judging the use end point of the film-forming liquid, comprising the following steps: measuring the viscosity of the film-forming liquid (alginate solution, with a mass concentration of 0.8%) used in the process of preparing crisp capsules for cigarettes by a single-hole method every 0.5h; drawing The change curve of viscosity with time, the viscosity reaches the lowest value, and then rebounds, and the time corresponding to the lowest value is the end of use of the film-forming liquid. When the film-forming liquid reaches the end of use according to the above method, replace the film-forming liquid; or stop dripping immediately if the viscosity is found to increase, and replace the film-forming liquid.

Embodiment 2

[0031] A method for judging the use end point of the film-forming liquid, which differs from Example 1 only in that the time interval for measuring the viscosity is 2 hours. When the film-forming liquid reaches the end of use according to the above method, replace the film-forming liquid; or stop dripping immediately if the viscosity is found to increase, and replace the film-forming liquid.

Embodiment 3

[0033] A method for judging the use end point of the film-forming liquid. The difference from Example 1 is that the time interval for measuring the viscosity is 1 hour; the film-forming liquid alginate solution used has a mass concentration of 1%. When the film-forming liquid reaches the end of use according to the above method, replace the film-forming liquid; or stop dripping immediately if the viscosity is found to increase, and replace the film-forming liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com