Industrial internet-based leather optimization layout and multimachine coordinated cutting method

An industrial Internet and leather technology, applied in the field of clothing fabrics, can solve the problems of low material utilization rate, low degree of automation, low production efficiency, etc., and achieve the effect of saving manpower and material resources, improving production efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical solution, technical purpose and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

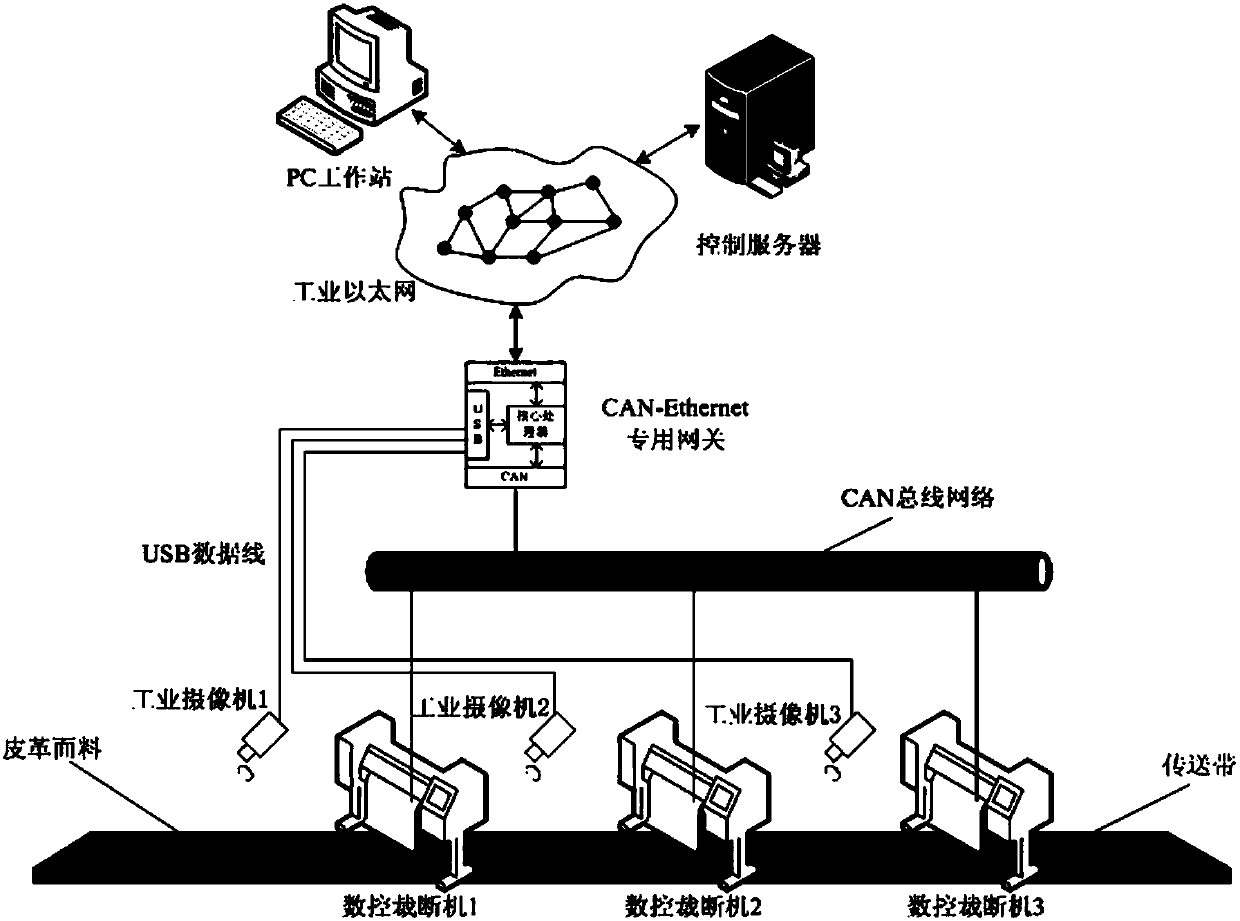

[0015] The network system structure of the present invention is as figure 1 As shown, the three leather cutting machines are networked through CAN bus technology, and their working status is uploaded to the dedicated gateway in real time. The dedicated gateway converts the protocol and then transmits it to the industrial Ethernet. Finally, the networked PC workstation and Control server for real-time reads. At the same time, because it is necessary to design the layout strategy and plan the sample cutting sequence for the processed leather fabrics, an industrial camera is installed at the gantry in front of each CNC machine tool in the system to quickly take pictures of the leather fabrics in the conveyor belt, and It is transmitted to the dedicated gateway thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com