Coding method for digital identification

A digital identification and identification code technology, applied in the field of digital identification, can solve the problems of easy tearing, low code reading efficiency, and falling off of the code spraying label, and achieve the effects of improving product quality control, high reading accuracy, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A specific embodiment of the present invention, such as Figure 8-11 As shown, a method for assigning digital identifiers is provided, including the following steps:

[0047] Step S1: detecting the state of the ink drop on the coding printing head 209 through the ink drop observation unit;

[0048] Step S2: Print and verify the identification code on the printed circuit board through the dynamic inkjet unit 8; after the verification of the identification code is completed, the identification code is cured by the ultraviolet curing unit 6 to complete the coding of the printed circuit board;

[0049] Step S3: Step S2 and Step S3 are repeated to complete the coding of multiple printed circuit boards.

[0050] In the step S1, the ink drop observation unit includes: a high-speed synchronous camera and a strobe LED light.

[0051] Further, while the stroboscopic LED lights flicker, the high-speed synchronous camera takes pictures of the ink droplets ejected by the coding pr...

Embodiment 2

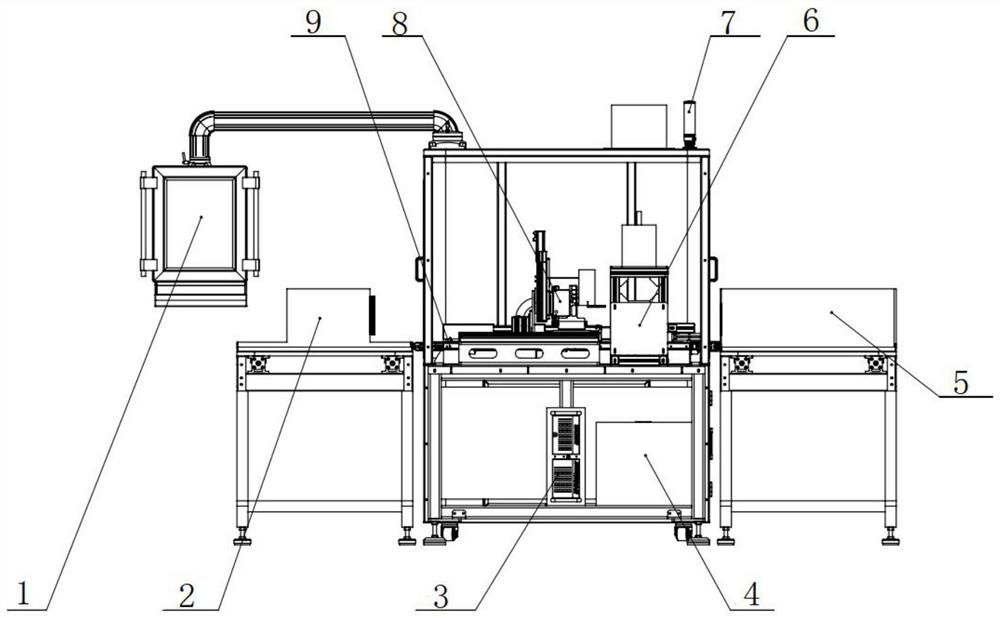

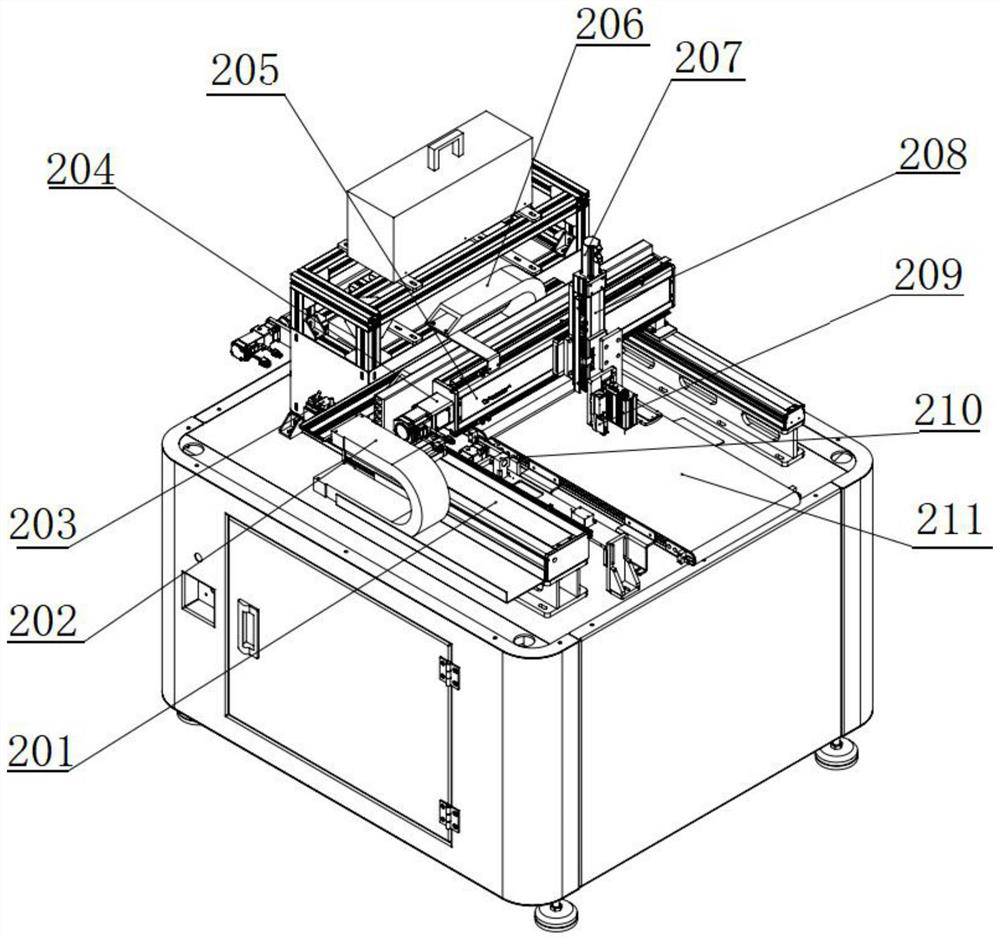

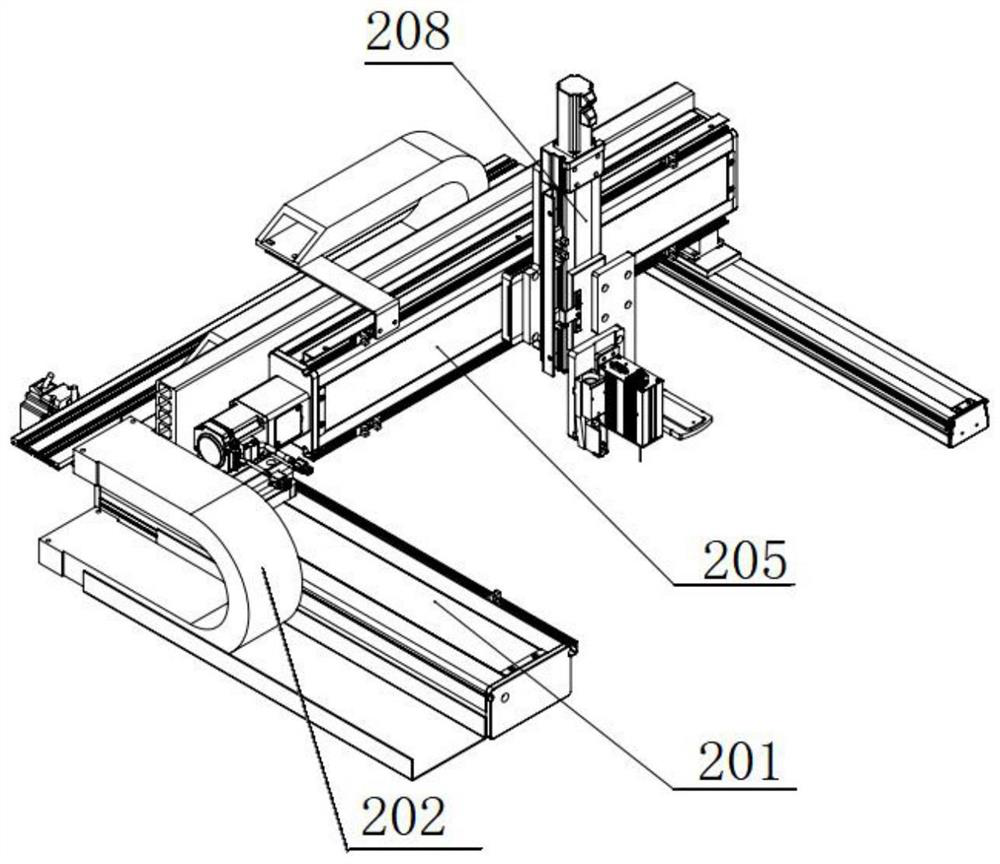

[0078] A specific embodiment of the present invention discloses a coding device for implementing the coding method in Embodiment 1, which is used for coding and marking printed circuit boards. Specifically, such as Figure 1-7 As shown, the coding equipment of the present invention includes: a display screen 1, a feeding mechanism 2, an industrial computer 3, a battery 4, a receiving mechanism 5, an ultraviolet curing unit 6, a warning light 7, a dynamic inkjet unit 8, and a belt transmission mechanism 9.

[0079] In this embodiment, the object to be coded is a printed circuit board. The dynamic inkjet unit 8 is used for spraying ink droplets on the object to be coded to form an identification code, and the identification code is a metal dot matrix pattern.

[0080] Such as figure 1 As shown, the display screen 1 is connected to the casing of the coding device through the cantilever, and the display screen 1 is connected to the cantilever in rotation; the display screen 1 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com