Lifting base bracket

A technology of seat bracket and base, which is applied in the field of mechanical parts processing, and can solve the problem that the support frame does not have a calibration structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

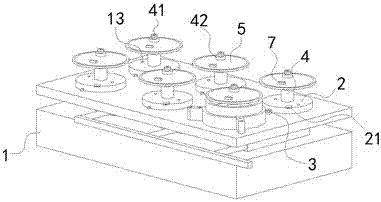

[0031] Embodiment one, such as figure 1 , figure 2 , image 3 and Figure 4 The lifting seat bracket has a workbench 1, and several bases 2 are arranged on the workbench 1, and the base 2 is riveted on the workbench 1 through rivets. This application considers the cost and the time consumed for replacing the processing parts, and now we can set up six A base of 2 is the optimal setting. Fixing pieces 13 are arranged on the workbench 1 around the base 2 to fix the processing parts.

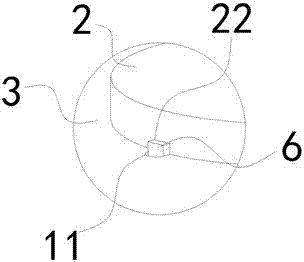

[0032] A calibration structure 3 is provided between the base 2 and the workbench 1. The calibration structure 3 includes lower and upper channels 11 and 22 respectively set on the workbench 1 and the base 2, and between the lower and upper channels 11 and 22. A calibration block 6 is provided, and is riveted with the workbench 1 by penetrating the base 2 and the calibration block 6 with two rivets. The calibration block 6 is partly outside the base 2 and exposed on the workbench 1 .

[0033...

Embodiment 2

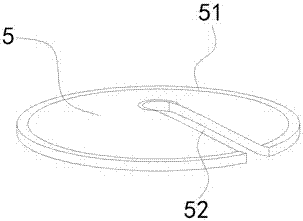

[0037] In the second embodiment, on the basis of the first embodiment, an outer edge 51 is provided on the detachable pressure plate 5 to fit the processed parts. The outer edge 51 can be fixed on the outermost side of the detachable pressure plate 5 to wrap the processed parts, and the outer edge 51 can also be fixed on the inner side of the detachable pressure plate 5 to support the inner cavity of the processed parts.

Embodiment 3

[0038] Embodiment three, such as figure 1 , figure 2 , image 3 and Figure 4 The detachable pressure plate 5 is provided with a synchronous supercharging device 7 to realize the close fit between the detachable pressure plate 5 and the processing parts. The synchronous supercharging device 7 has six evenly distributed around the detachable pressure plate 5 . The synchronous supercharging device 7 has a vacuum suction cup 71, the tail of the vacuum suction cup 71 is provided with a cavity, a rubber piston is placed in the cavity, a connecting rod is fixed on the rubber piston, and the connecting rod extends out of the surface of the detachable pressure plate 5 to connect to the cross bar; The tail of the vacuum suction cup 71 is connected with an ejection structure 72, and the ejection structure 72 has an ejection cavity, and a rubber piston is arranged in the ejection cavity, and an ejection connecting rod is fixed on the rubber piston, and the ejection connecting rod and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com