Manufacture method for low polarization sensitivity dichroic film of medium metallic film pile

A production method and metal film technology, applied in optical components, optics, instruments, etc., can solve the problems of difficulty in ensuring low polarization sensitivity, large errors, and many film stacks, so as to ensure design functions, prevent production errors from accumulating and magnifying, Easy to monitor the effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] The specific embodiments of the present invention will be described below based on examples and drawings.

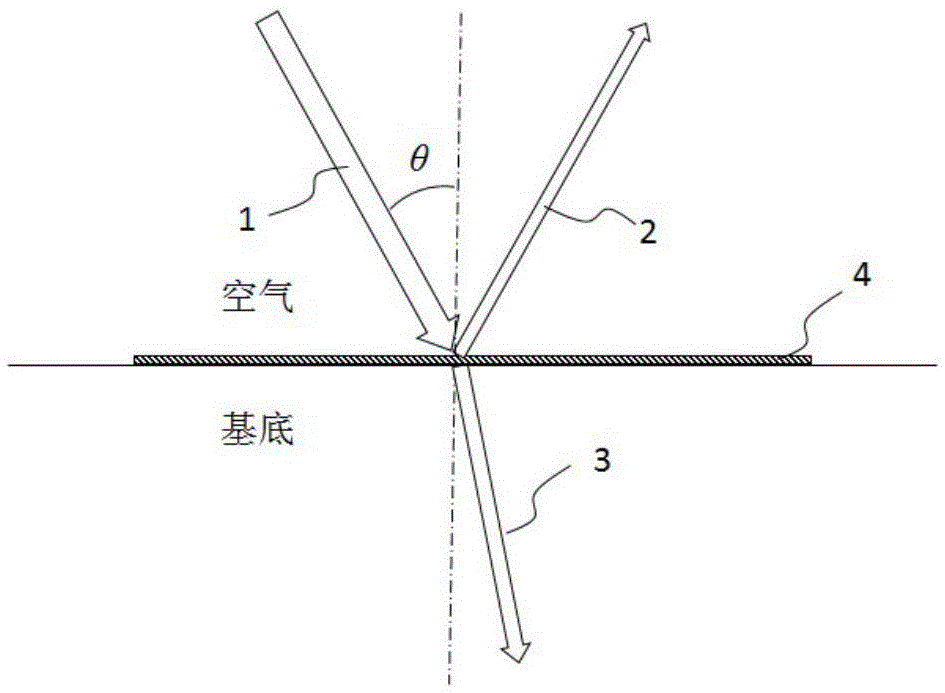

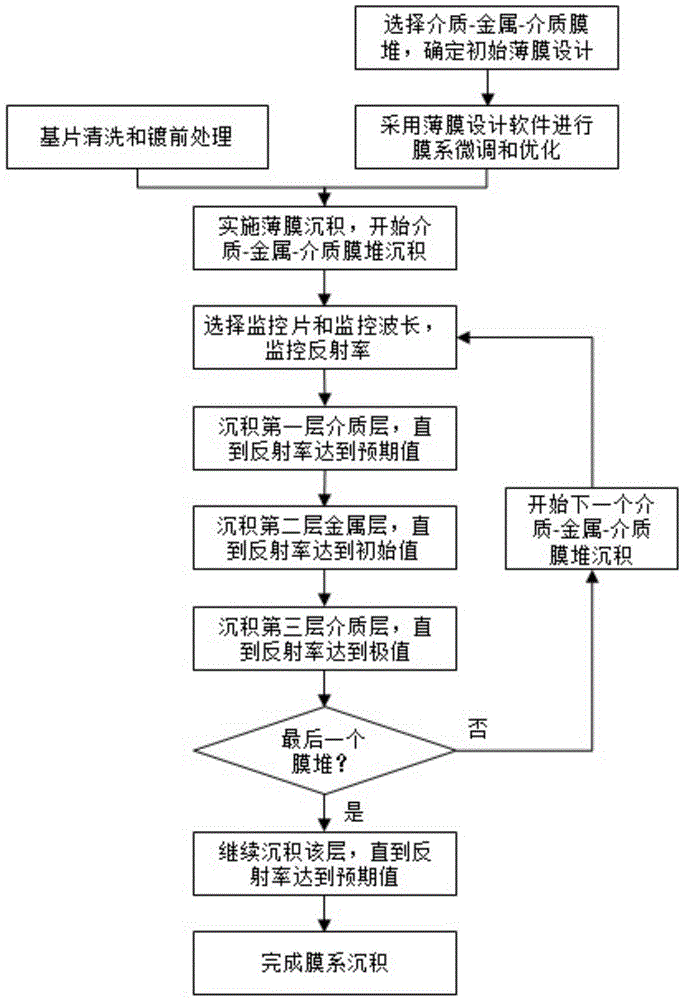

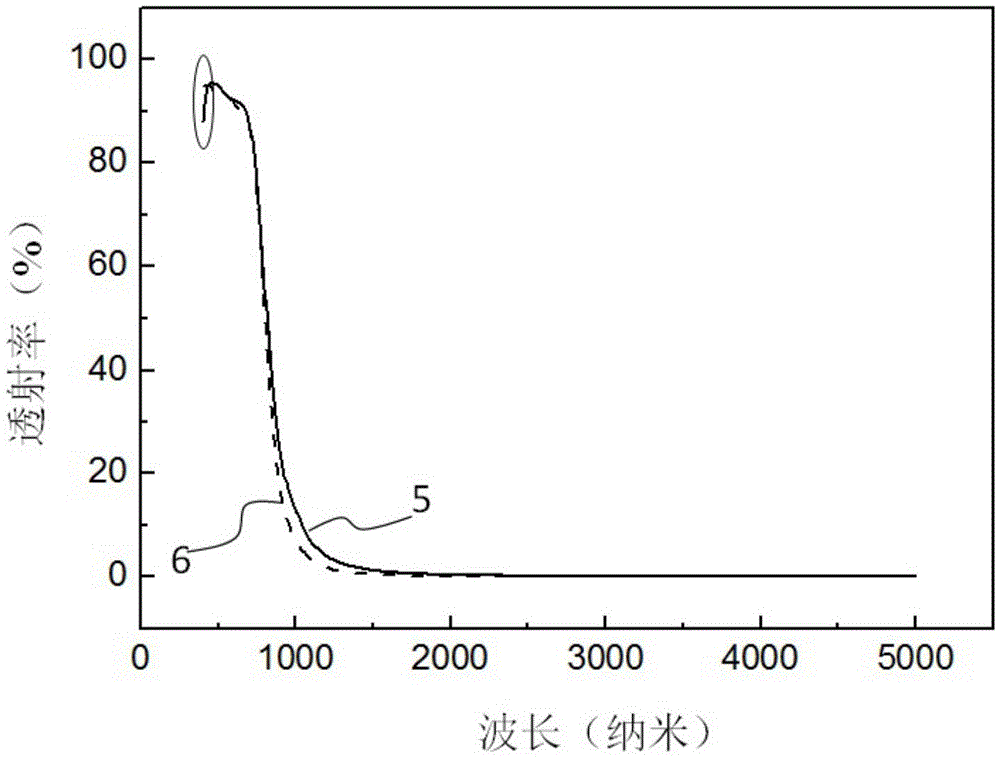

[0023] Take the production of a low polarization sensitivity dichroic film system working in an air environment at 45° incidence as an example. The film system requires reflection of all wavelengths greater than 2000nm, transmission of visible light of 400-700nm, and requires the transmission of light to maintain polarization in the band The sensitivity is less than 1%. The substrate is made of fused silica. The traditional ZnS-Ag-ZnS film structure cannot meet the requirements of low polarization sensitivity. If the coating material is selected as Ta 2 O 5 , Ag and SiO 2 The manufacturing method proposed by the present invention can meet the control requirements of low polarization sensitivity, and the specific implementation is as follows:

[0024] 1) According to the admittance matching method, the designed preliminary film structure is quartz / (38.9nmTa 2 O 5 / 9.4nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com