Display base plate and manufacturing method of display base plate as well as display device

A display substrate and substrate substrate technology, which is applied in optics, instruments, electrical digital data processing, etc., can solve the problems of low light transmittance, thick module, high production cost of external touch screen, etc., to improve signal-to-noise Ratio, the effect of improving touch sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the structure and principle of the present invention will be described in detail below in conjunction with the accompanying drawings. The examples given are only used to explain the present invention, not to limit the scope of protection of the present invention. .

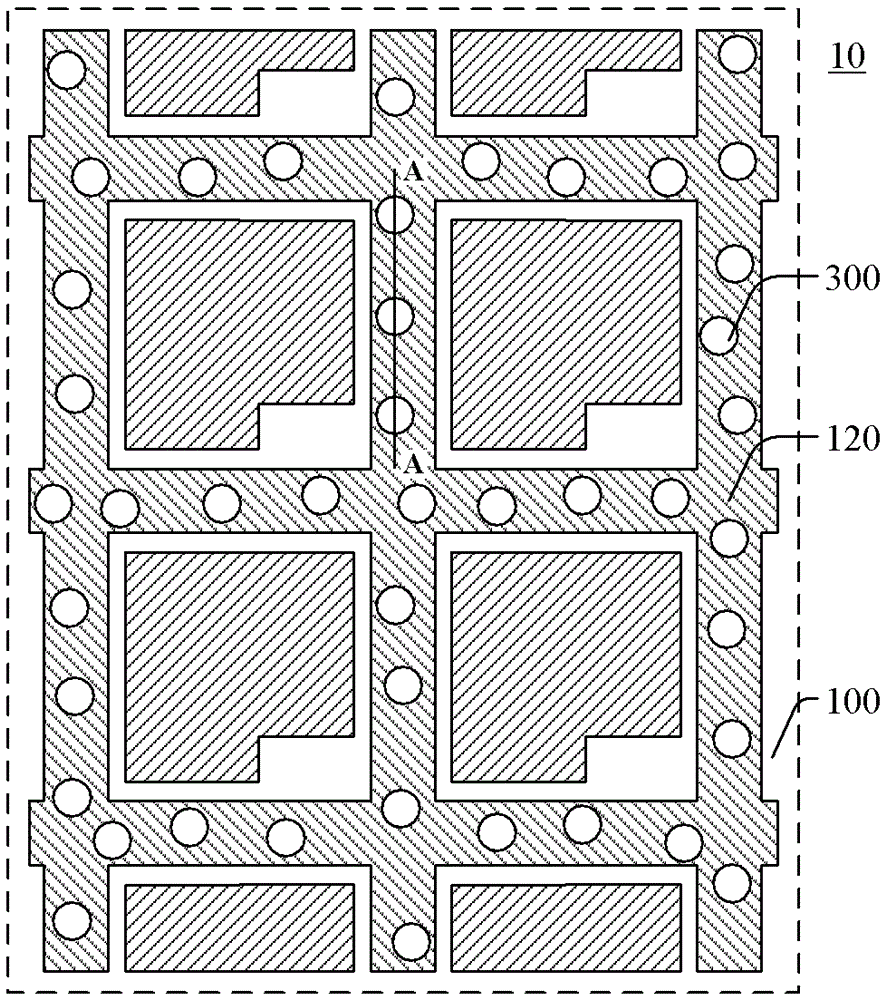

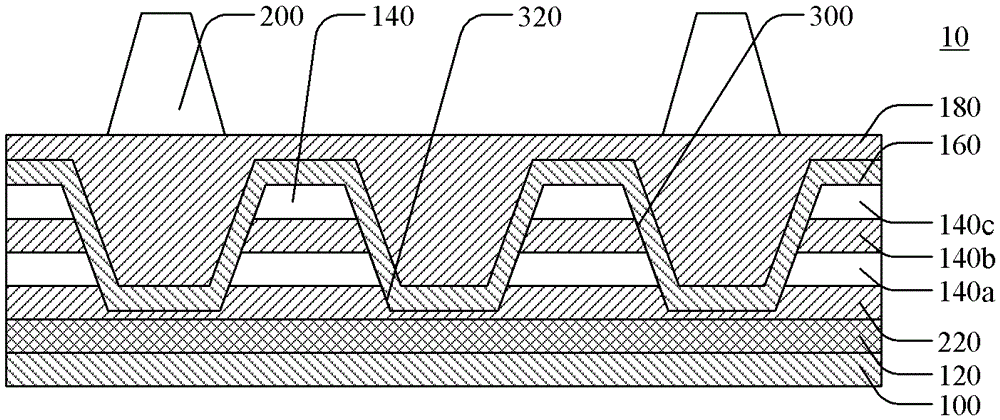

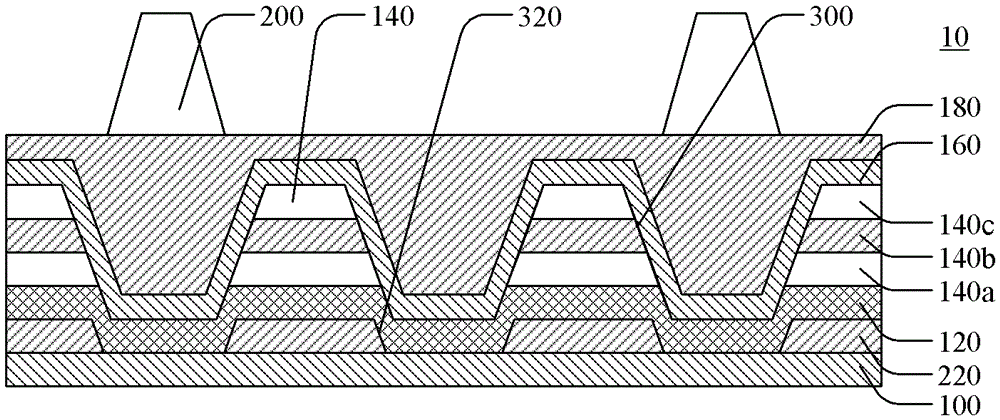

[0038] The components shown in the drawings are marked as follows: 10 display substrate; 100 base substrate; 120 black matrix; 140 filter layer stack; 140a, 140b, 140c color filter layer; 160 touch electrode; 200 a spacer; 220 a first protective layer; 300 an opening; 310 a first depression; 320 a second depression; 330 a third depression.

[0039] figure 1 It is a schematic top view of a part of a display substrate according to an embodiment of the present invention. Figure 2A , 2B , 2C, 2D and 2E are respectively along figure 1 Schematic cross-sectional view of line A-A. As shown, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com