A Method of Correcting the Actual Measurement Value of Hot Rolling Process Temperature

A technology of hot rolling process and actual measurement value, which is applied in metal rolling, length measuring device, metal rolling, etc., and can solve problems such as inability to effectively deal with impact, abnormal temperature measurement value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

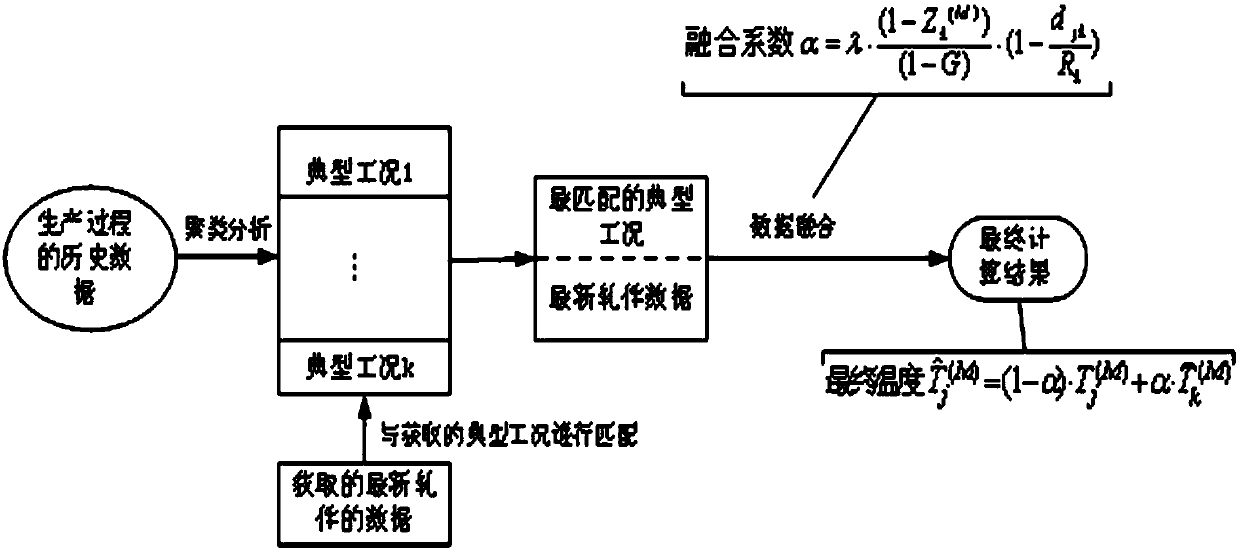

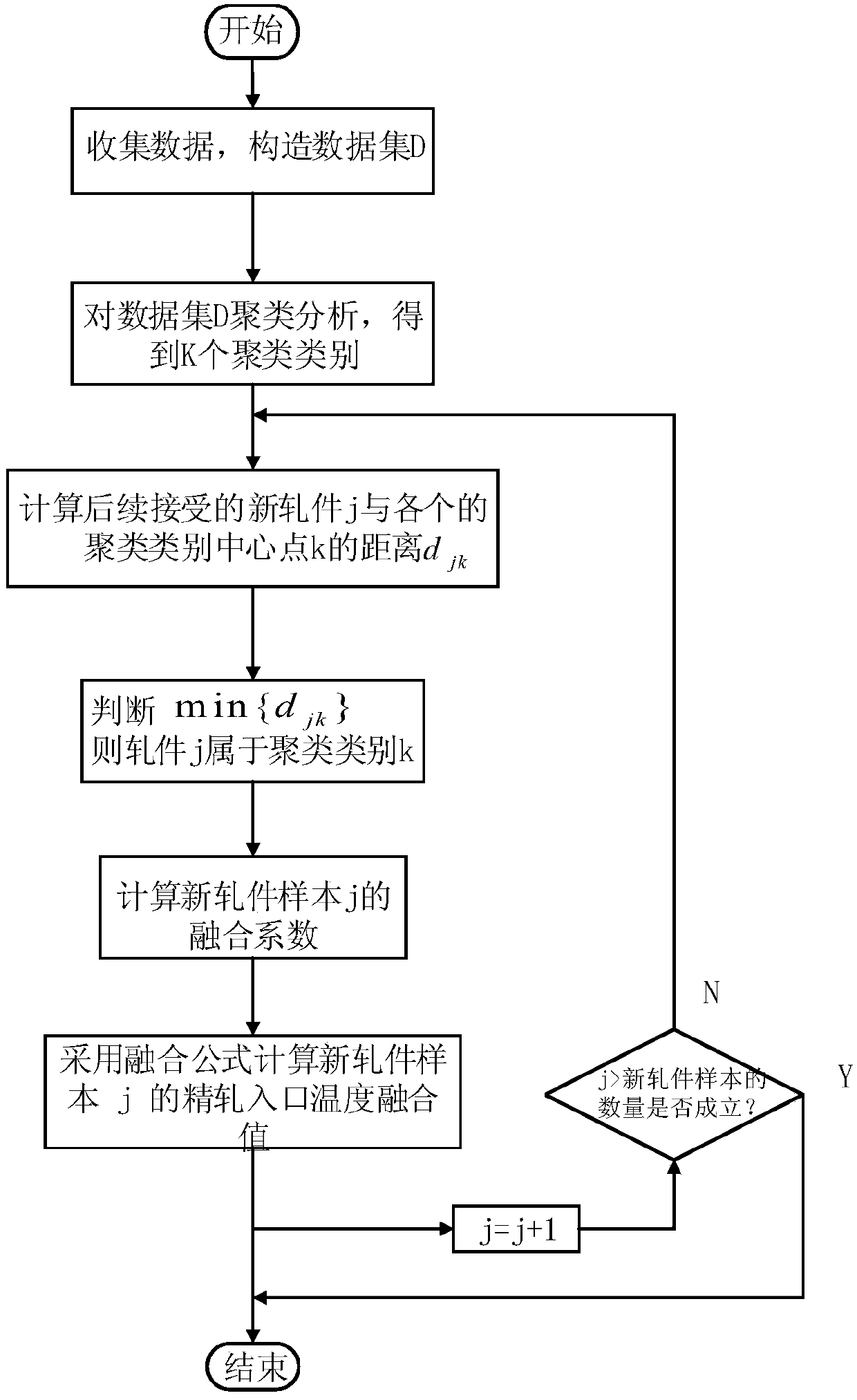

[0034] A method for correcting the measured value of the temperature in the hot rolling process. The method first collects the production data of historical rolled pieces in the hot rolling process, and obtains the production data of historical rolled pieces by performing cluster analysis on the production data of the historical rolled pieces. According to the typical working conditions of the current rolling piece and the production data of the current rolling piece, the working conditions of the current rolling piece and the historical rolling piece are matched, and then the data is fused to correct the measured temperature value of the current rolling piece to obtain the corrected temperature of the current rolling piece Measurements.

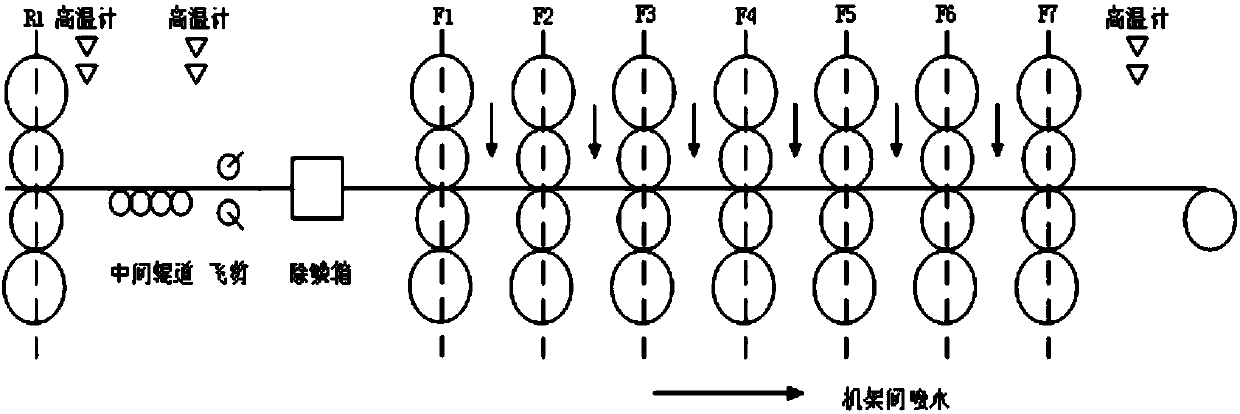

[0035] The production data includes the measured temperature value of the rolled piece measured by the pyrometer on the production line during the hot rolling process and the rolling process parameter value related to the rolled piece tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com