Camera module motor, camera module and electronic device

A technology for camera modules and electronic equipment, applied to televisions, electrical components, color TVs, etc., can solve the problems of multiple spaces for magnets 3, large camera module volume, and large camera module motor volume, and achieve simplified assembly process, Solve the effect of large volume and reduce the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

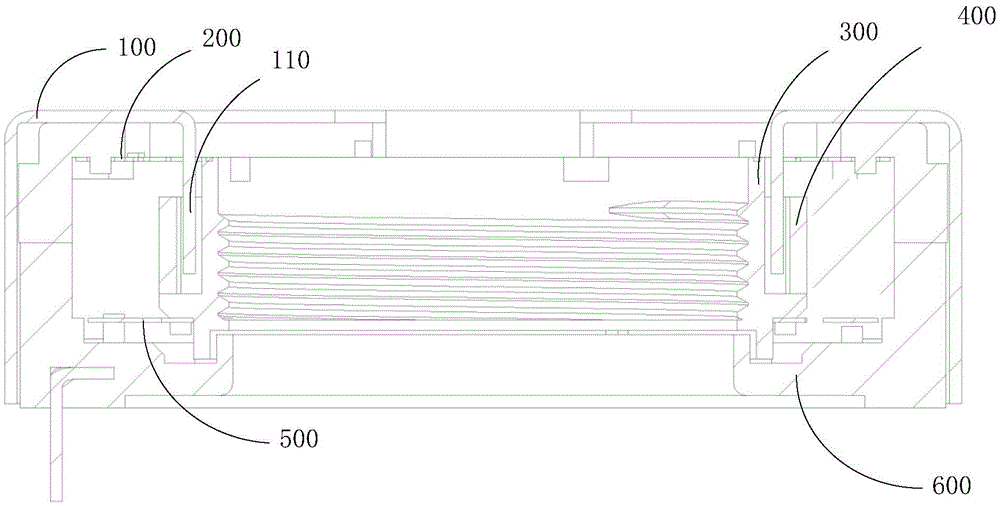

[0021] As mentioned in the background art, the camera module motor in the prior art needs a magnet to provide a magnetic field, which leads to a large volume of the camera module motor, and thus makes the camera module using the camera module motor Larger volume.

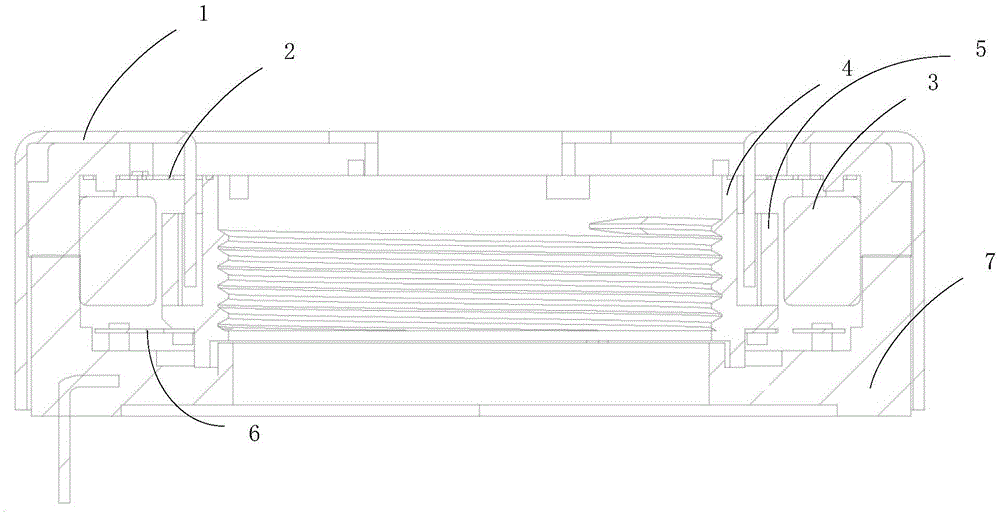

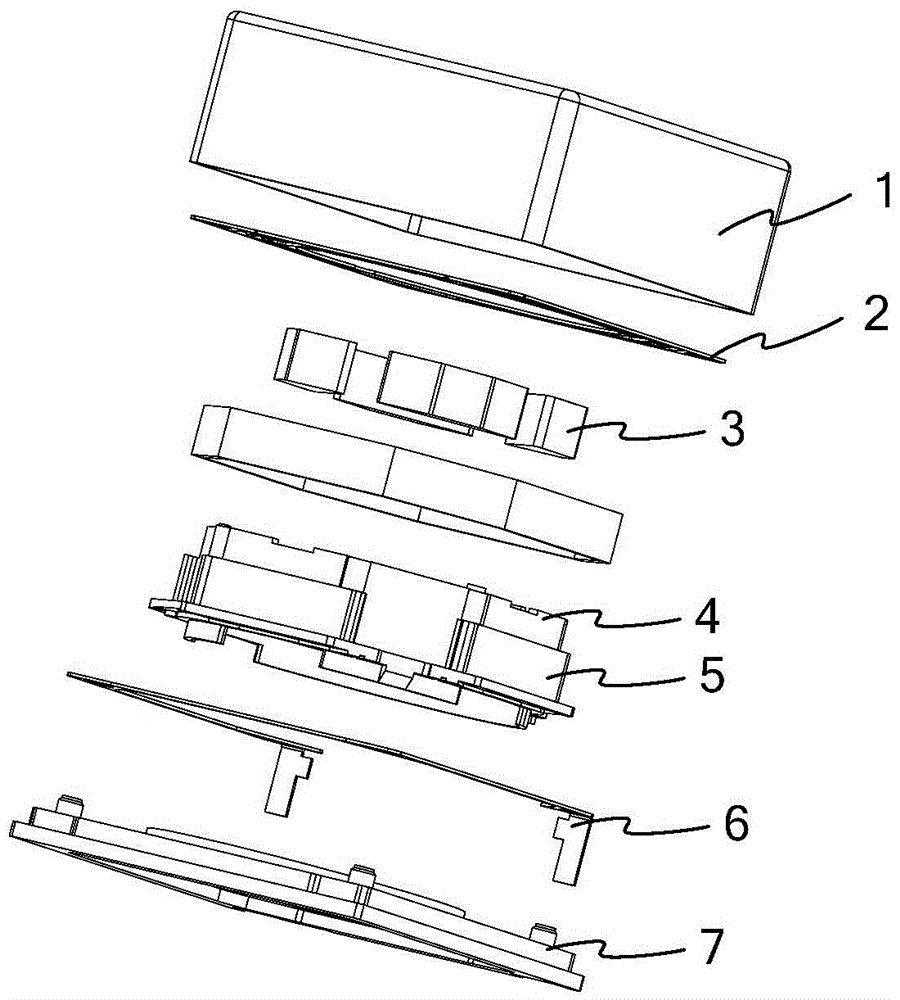

[0022] In view of this, the embodiment of the present application provides a camera module motor, which includes a housing, an upper elastic piece, a lens carrier, a coil, a lower elastic piece and a base, and the housing and the base form a hollow receiving cavity after fitting , the upper elastic piece, the lens carrier, the coil and the lower elastic piece are located in the storage cavity, and the lens carrier accommodates a lens;

[0023] Wherein, the yoke of the housing is magnetic.

[0024] Correspondingly, the embodiment of the present application also provides a camera module, including at least one lens and camera module motors corresponding to the number of lenses, and the camera module motor is the came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com