A water-cooled heat dissipation structure for a drive motor and a motor controller

A motor controller and water cooling technology, which is applied in the field of automobile manufacturing, can solve the problem of uneven heat dissipation of a single-channel cooling water circuit, and achieve the effects of preventing heat redundancy, avoiding heat concentration, and balancing the flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

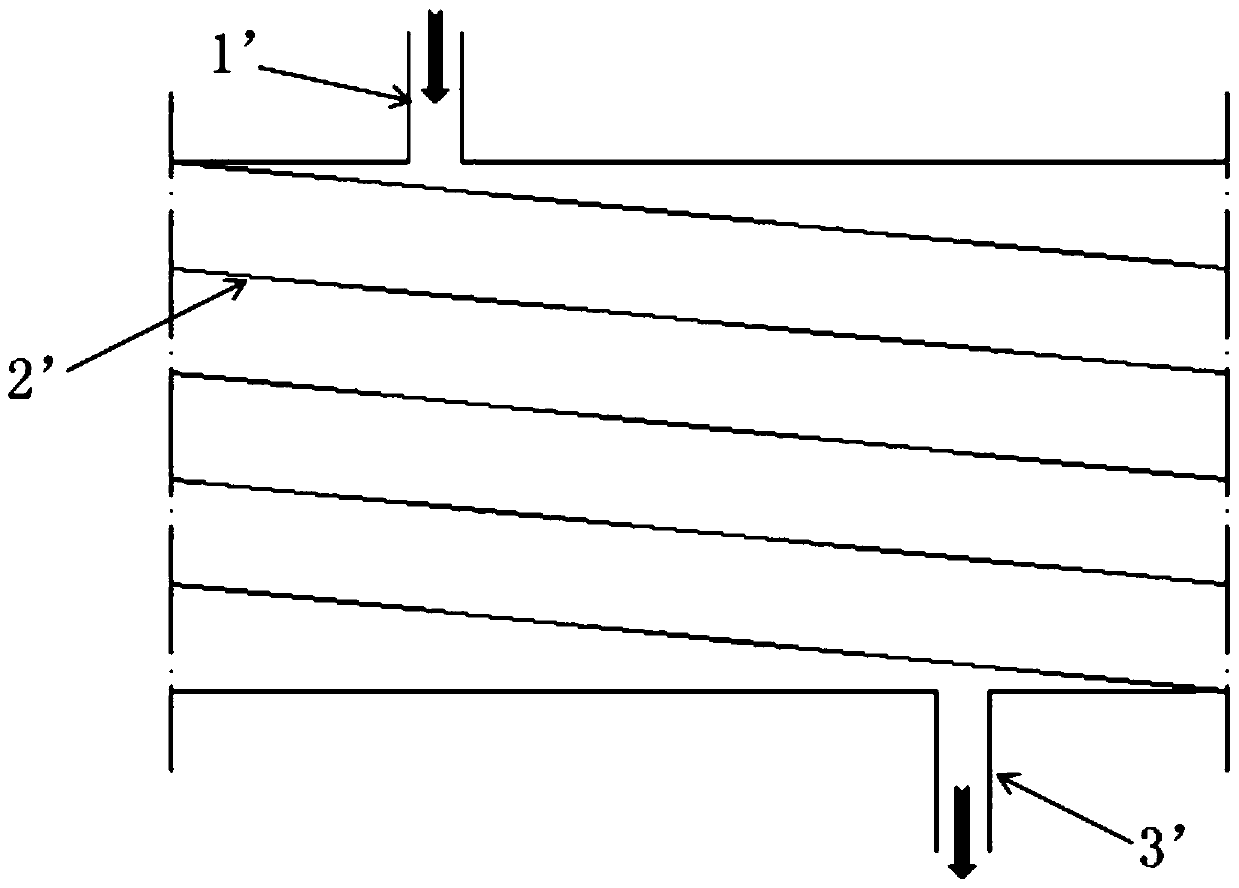

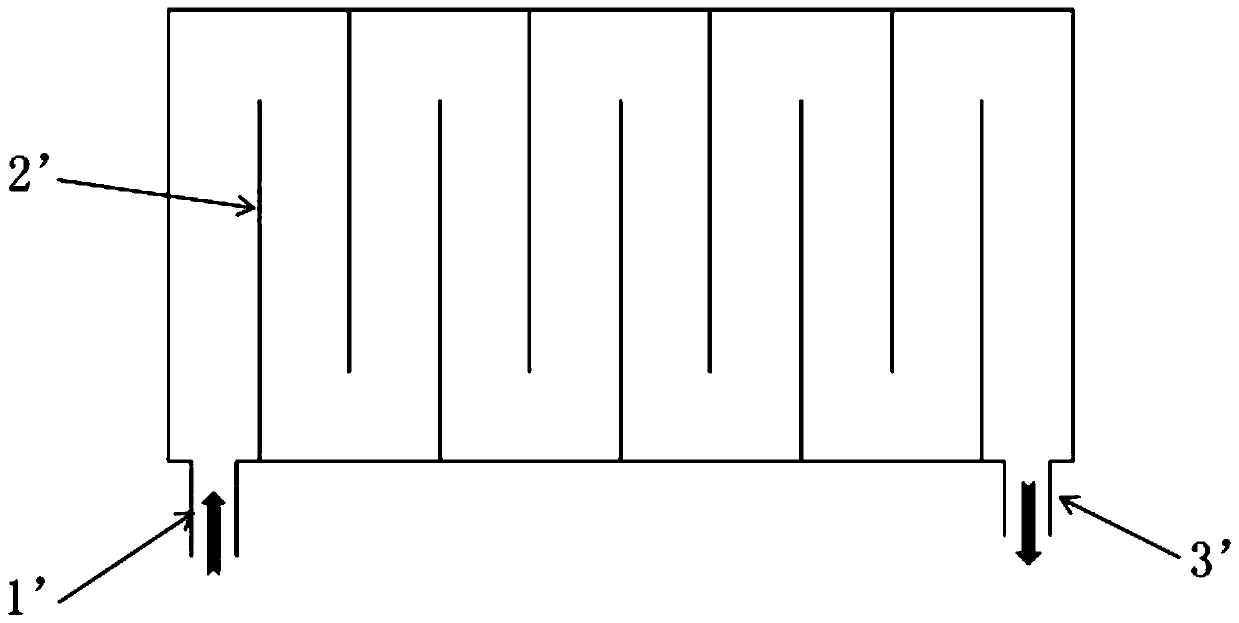

[0017] Please also refer to Figures 1 to 2 , the figure shows two existing single-channel water-cooling heat dissipation structures, that is, spiral and S-shaped, both of which can form a continuous cooling medium channel, but both have the problem of heat concentration at the end of the flow channel.

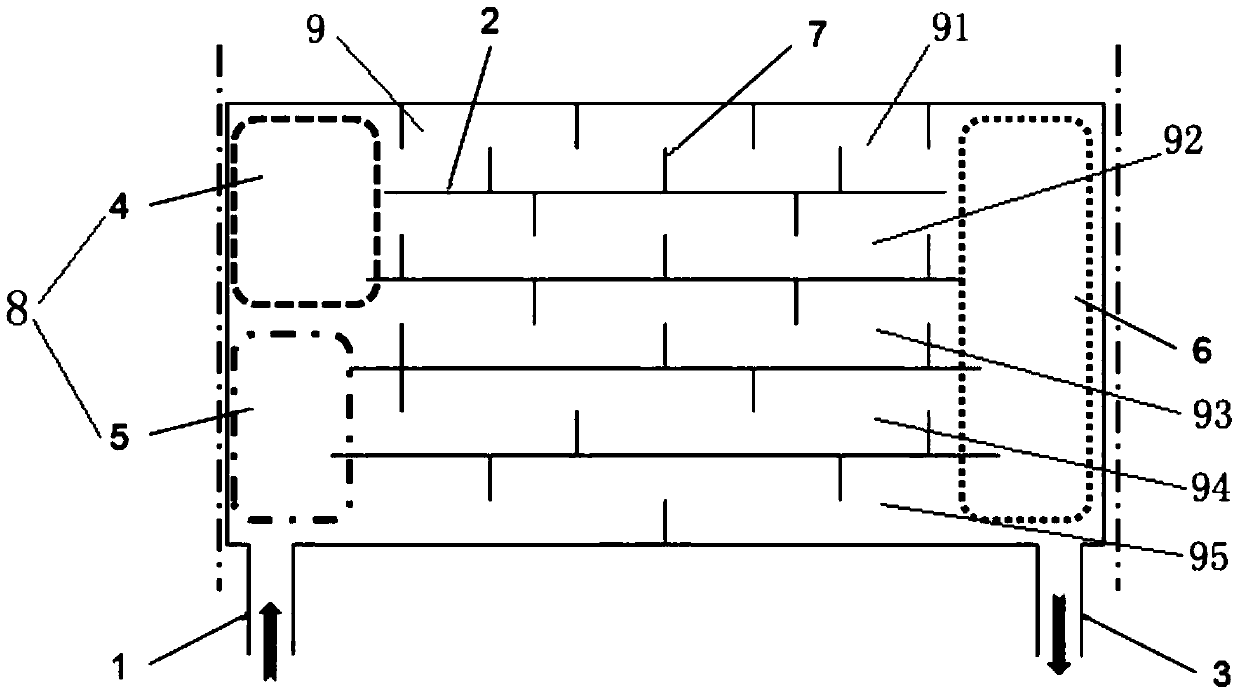

[0018] Examples, see image 3 , a water-cooled heat dissipation structure for driving a motor and a motor controller, comprising a cooling medium inlet 1 and a cooling medium outlet 3, a high-pressure area 8 arranged on the side of the cooling medium inlet 1, and a low-pressure area arranged on the side of the cooling medium outlet 3 6, and five cooling channels 9 arranged between the high pressure area 8 and the low pressure area 6.

[0019] Among them, the high-pressure area 8 is composed of a sub-high pressure area 5 and a high-pressure area 4, the cooling medium inlet 1, the sub-high pressure area 5 and the high-pressure area 4 are arranged linearly in sequence along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com