A punching device

A thread-passing and punching needle technology, which is applied in medical science, surgery, etc., can solve the problems of threading and finding difficulties, and achieve the effect of enhancing the fixation effect, easy threading, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

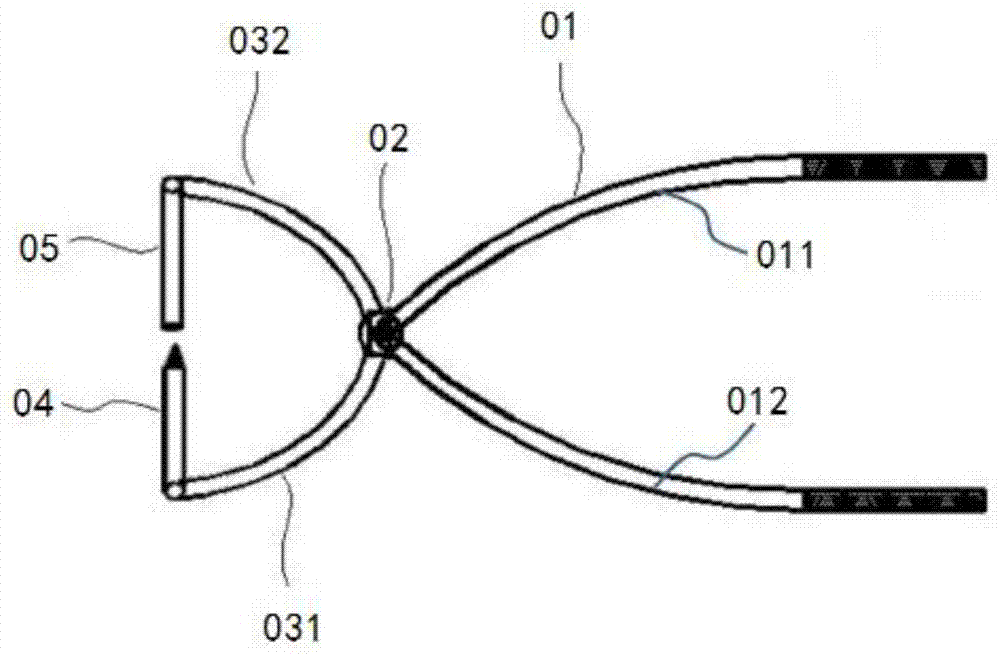

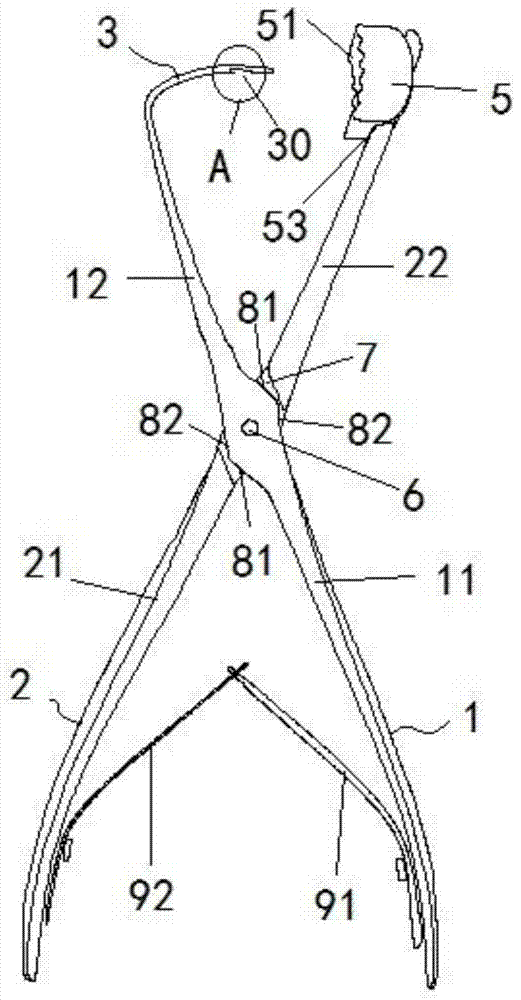

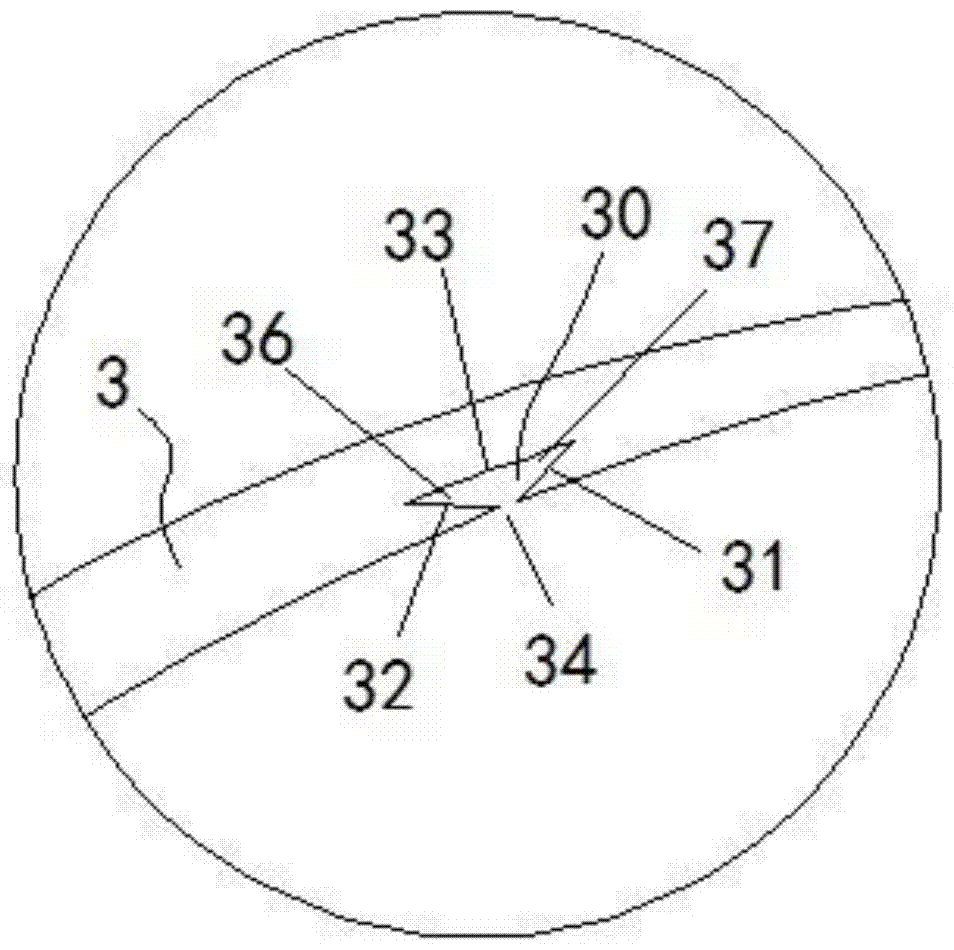

[0044] This embodiment provides a punching wire passing device, such as figure 2 As shown, it includes: a first pliers arm 1, a second pliers arm 2 and a connection structure, wherein the connection structure is used to rotatably connect the cross-placed first pliers arms 1 and the second pliers arms 2, and The first tong arm 1 is divided into a first operation section 11 and a first working section 12, the second tong arm 2 is divided into a second operation section 21 opposite to the first operation section 11, and The second working section 22 opposite to the first working section 12; also includes a perforating needle 3, which is arranged on the first working section 12 and has a threading hole or a threading groove 30 for threading; and a first through hole A hole is provided on the second working section 22, opposite to the perforating needle 3, allowing the perforating needle 3 to pass through.

[0045] In the punching and threading device of this embodiment, the punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com